Operating speed control system and method for combine harvester

A combined harvester and speed control technology, which is applied to harvesters, agriculture, cutters, etc., can solve the problems of low sensitivity of mechanical induction sensors, limited adjustment accuracy, and poor ability to feel the change of feeding amount, so as to reduce machine hands. The effect of reducing the number of operations, reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

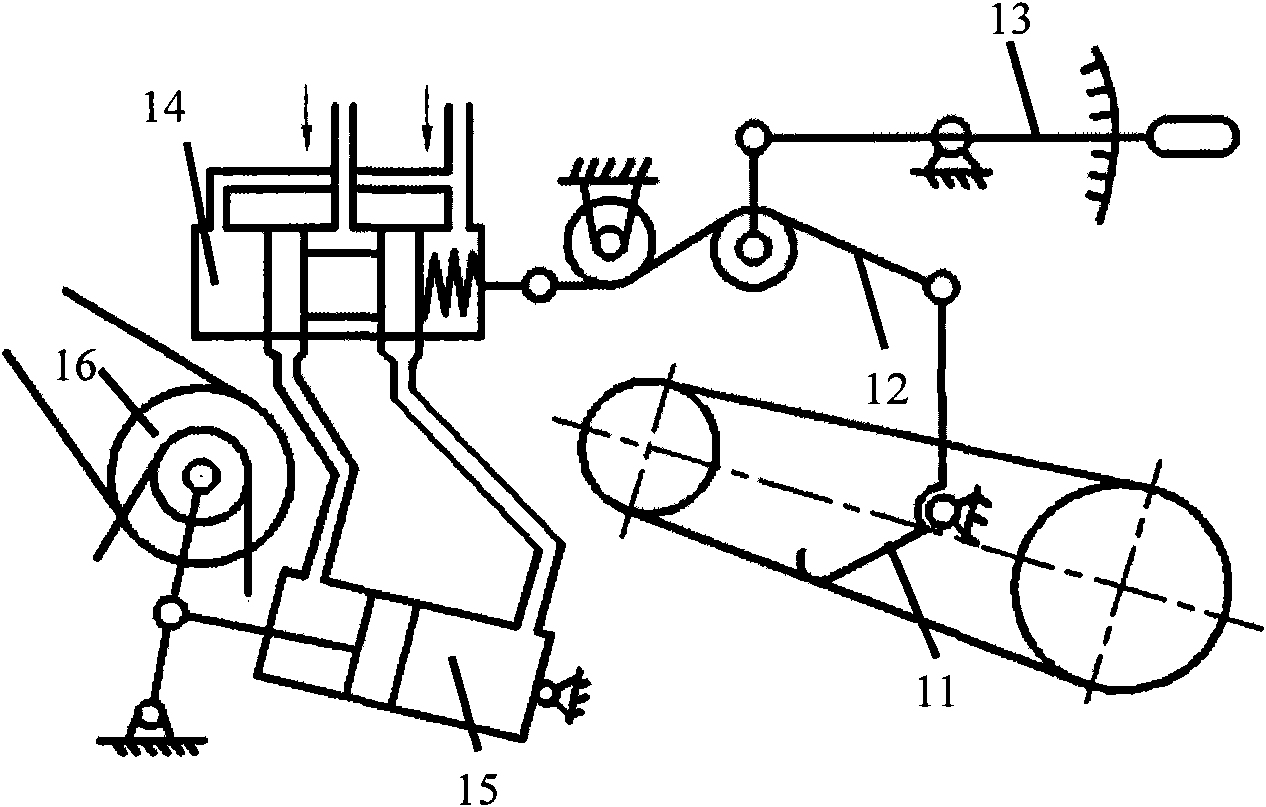

[0034] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

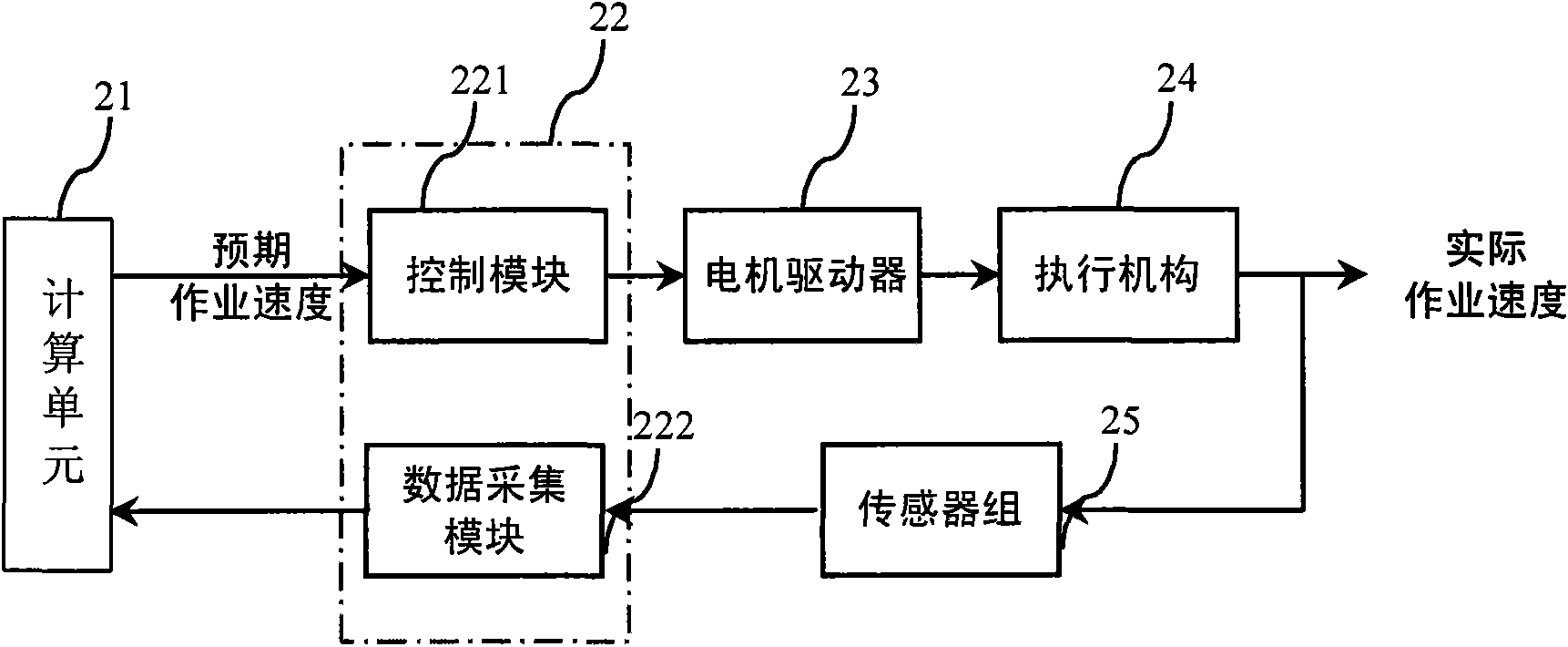

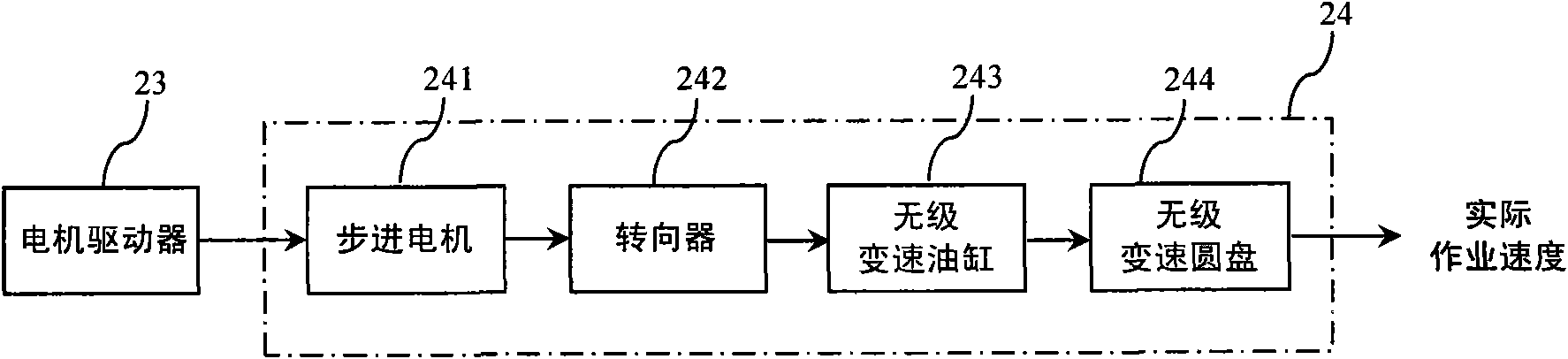

[0035] Such as figure 2 As shown, the combined harvester operating speed control system provided by the present invention includes a computing unit 21, which is used to process the received data and issue control instructions with the expected operating speed as the target; the measurement and control box 22 is used to collect sensor groups 25 The obtained data is transmitted to the calculation unit 21, and the control instruction of the calculation unit 21 is converted into a pulse control signal, and output to the motor driver 23; the motor driver 23 is used to receive the pulse control signal and control the actuator 24 according to the control Instruction work; the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com