High-strength electron beam welding process of titanium metal material and copper or copper alloy

An electron beam welding, titanium metal technology, applied in the welding process of titanium metal material and copper or copper alloy, titanium metal material and copper or copper alloy high-strength electron beam welding technology field, can solve the problems of poor plasticity and low joint strength, etc. , to achieve the effect of improving strength and plasticity, smoothing welds, and eliminating brittle compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

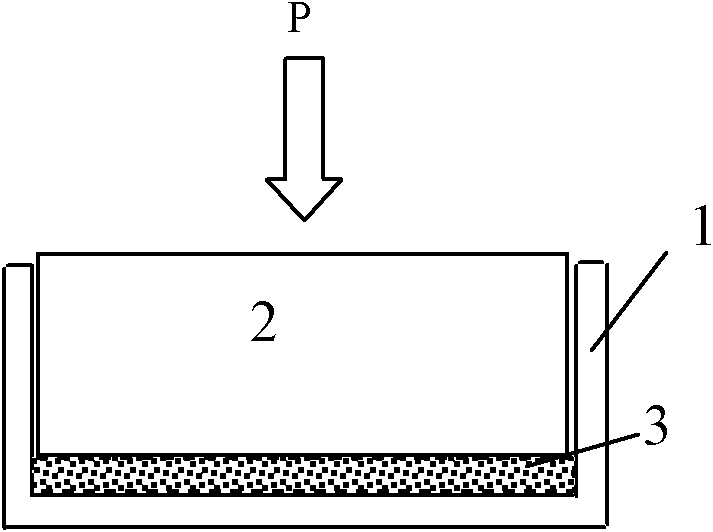

[0010] Specific implementation mode one: combine Figure 1-Figure 3 To illustrate this embodiment, the steps of a titanium metal material and copper or copper alloy high-intensity electron beam welding process in this embodiment are:

[0011] Step 1. Make filling material. In the special mold 1, fill the powder evenly mixed with vanadium powder and copper powder. The mass percentage of vanadium powder in the mixed powder is 20-70%, and the balance is copper powder. The mixed powder is put in the press Under the action of punch 2, it is formed by cold pressing, the pressure is 500-700Mpa, and the metal thickness of the filling layer after pressing is 0.5-2.0mm. Put the pressed filling layer into a vacuum heating furnace at a temperature of 830-970℃ Diffusion treatment is carried out for 1-6h to form a filling layer, which is a vanadium-copper alloy layer 3;

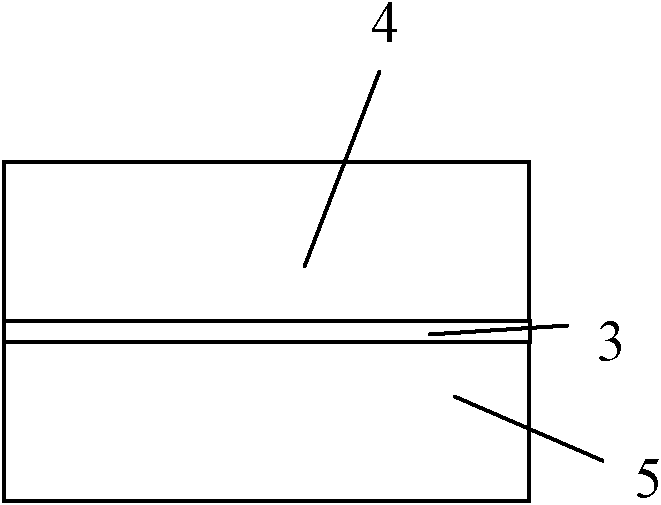

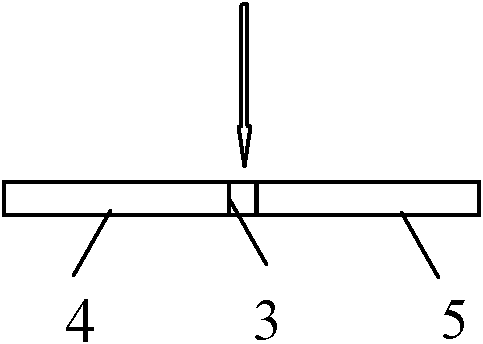

[0012] Step 2, preset vanadium-copper alloy layer 3 in the butt joint of titanium metal material 4 and copper or copper...

specific Embodiment approach 2

[0014] Embodiment 2: The purity of the vanadium powder and the copper powder in the step 1 of this embodiment is above 99.9%. Other conditions and steps are the same as in Embodiment 1.

specific Embodiment approach 3

[0015] Embodiment 3: In step 1 of this embodiment, the particle size of the copper powder is 200-500 mesh, and the particle size of the vanadium powder is 200-500 mesh. Easy to shape. Other conditions and steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com