Regulating method of outlet lifting roller way of steel rail rolling mill

A technology of rail rolling mill and adjustment method, which is applied in metal rolling, metal rolling, metal processing equipment, etc., can solve problems such as side bending and hard bending defects, and achieve the effects of improving surface quality, reducing scratches, and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

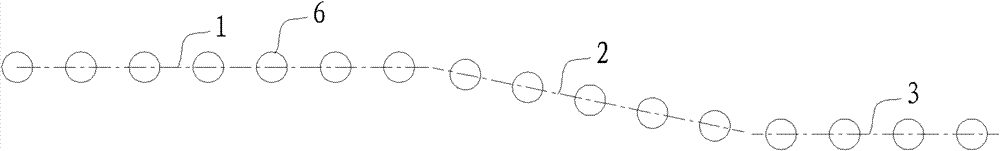

[0037] There are three universal rolling mills, universal intermediate milling and universal finishing mills in a certain universal rolling area, where E1, E2 and UF stands are the tapping stands of the three mills.

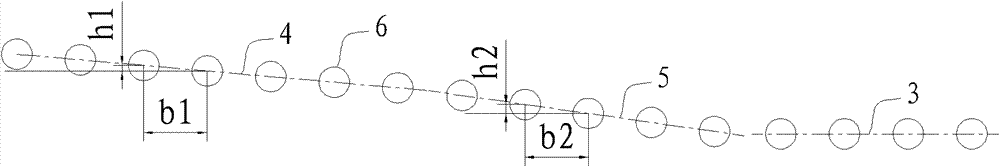

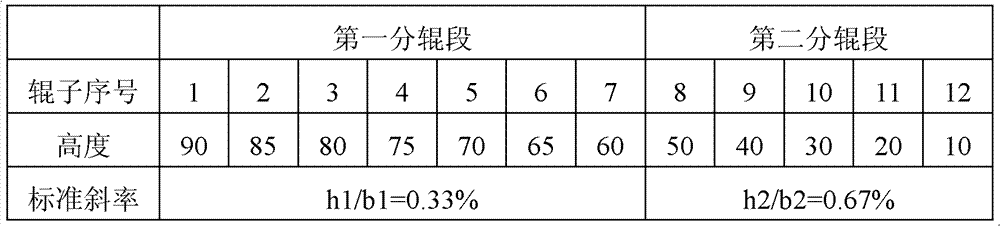

[0038] E1 and E2 racks have a length of 16.5m for the exit lifting roller table, 12 rollers are used, the diameter of the roller is 310mm, the horizontal distance between two adjacent rollers is 1500mm, the distance from the centerline of the first roller to the centerline of the roller It is 1950mm.

[0039] The length of the lifting roller table at the exit of the UF frame is 6m, using 5 rollers, the diameter of the roller is 310mm, the horizontal distance between two adjacent rollers is 1500mm, and the distance from the centerline of the first roller to the centerline of the roll is 1950mm. The entire exit lifting roller table is composed of a section of sub-roller table.

[0040] Process: Take the U75V 60kg / m rail as the standard rail, and establish the curve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com