Device for cold foil embossing

A technology of film and carrier film, which is applied in printing devices, printing and printing of special varieties of printed matter, and can solve problems such as inflexible application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

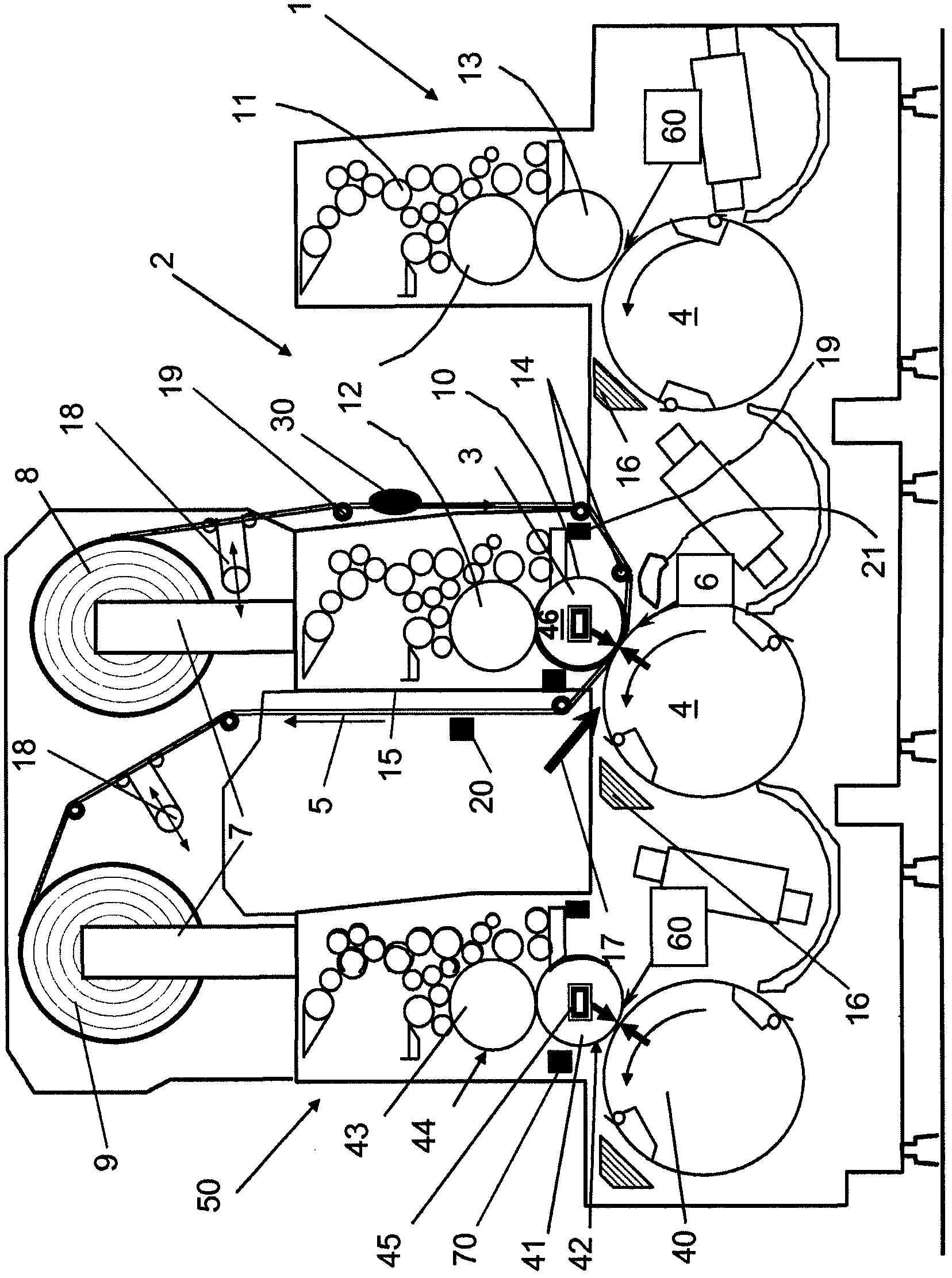

[0028] figure 1 Shown are parts of a sheet-fed rotary press (Bogenrotationsdruckmaschine), which comprises two printing units and is used for the following purposes:

[0029] - First, the printed paper is provided with a planar or image-imparting adhesive pattern (printing unit as application unit (Auftragwerk) 1 ).

[0030] - In the subsequent printing unit, the printing paper is guided under pressure together with the transfer film 5 through the transfer nip 6, (coating unit 2 ).

[0031] The application unit 1 can be a known offset printing unit with an inking unit 11 , a plate cylinder 12 and a cloth cylinder 13 . The cloth cylinder 13 cooperates with the impression cylinder 4 .

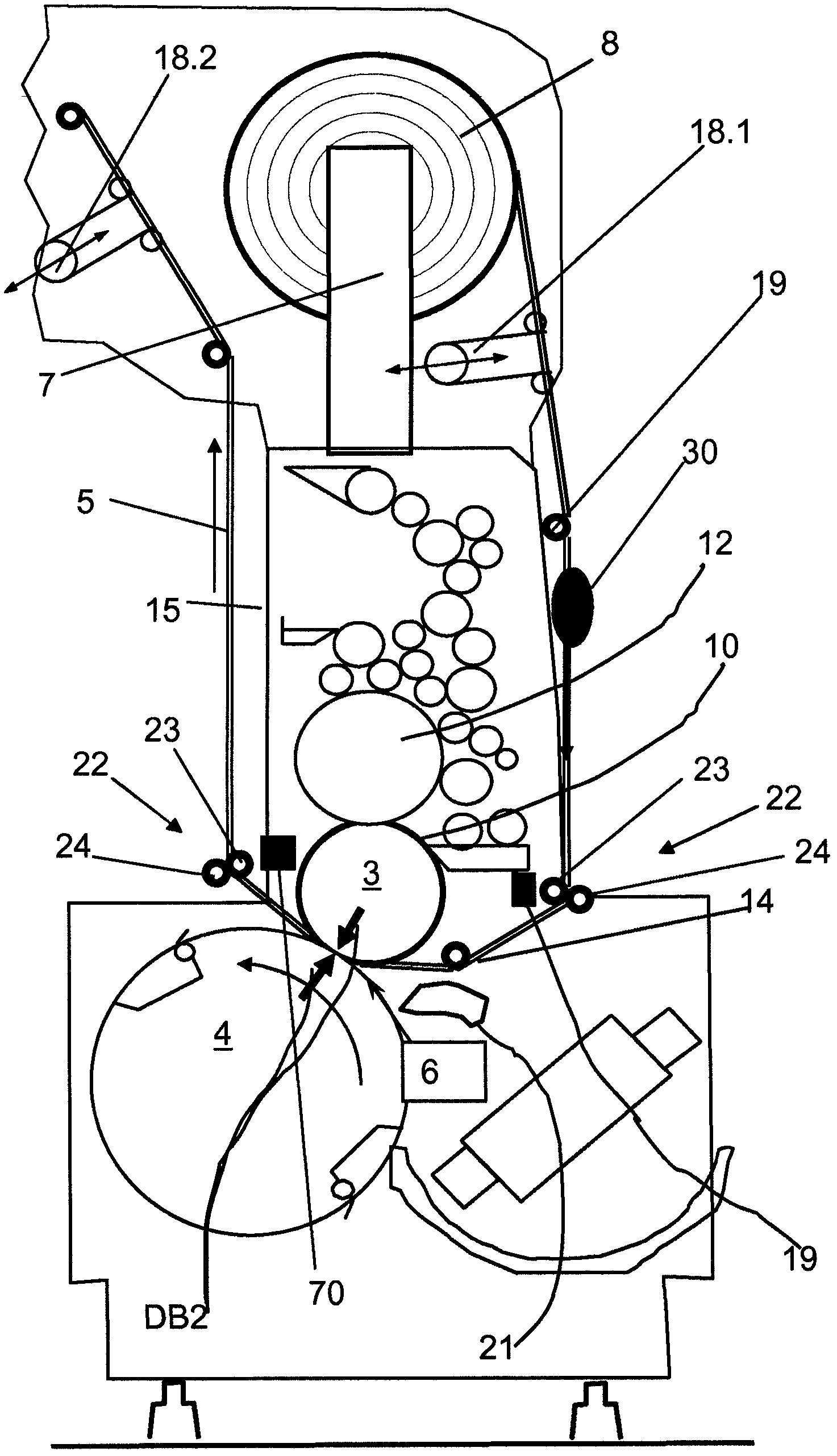

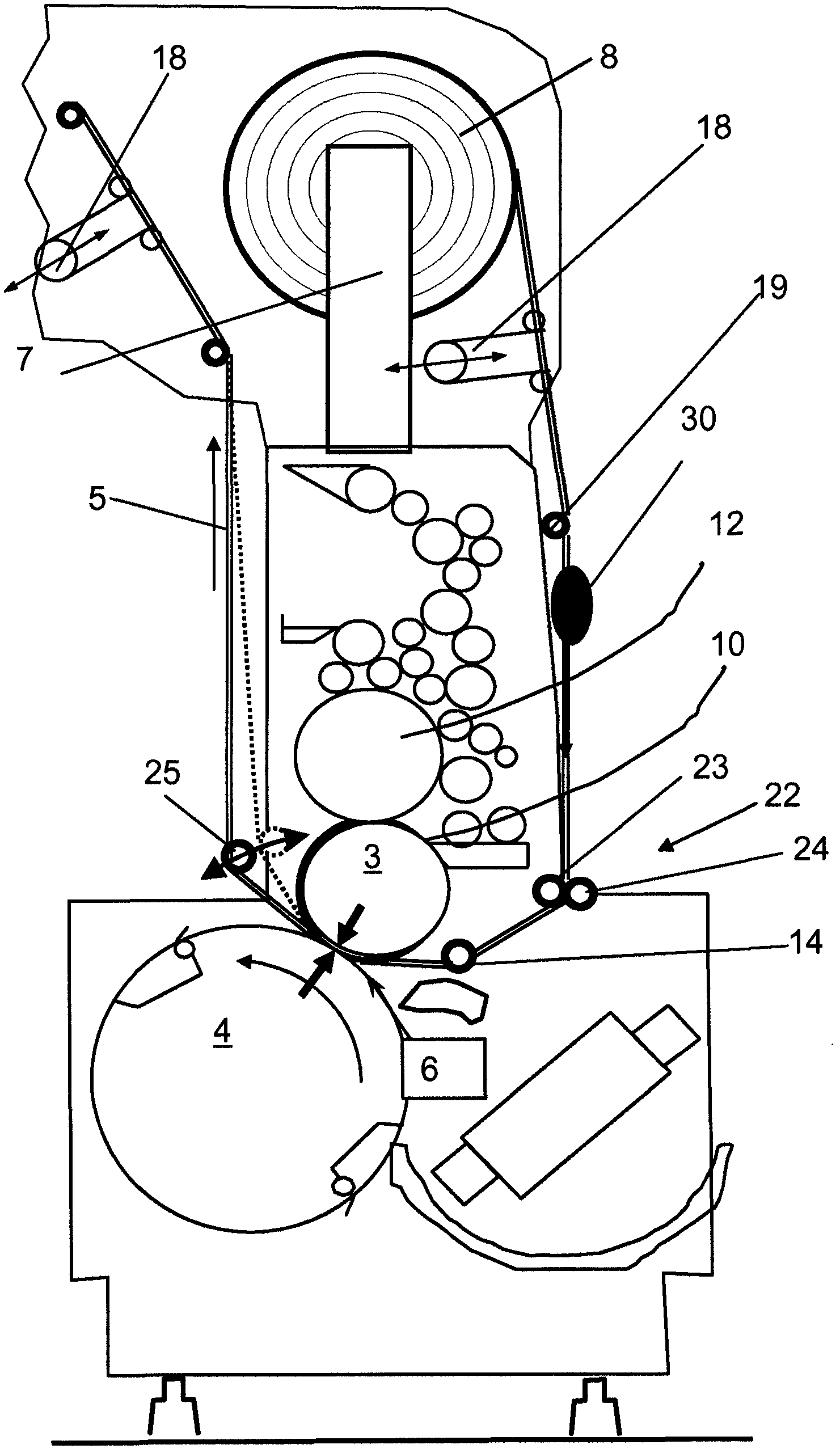

[0032] Likewise, the coating means 2 can be formed by a lithographic means. The transfer nip 6 in the coating unit 2 is formed by the pressure roller 3 and the impression cylinder 4 . The pressing roller 3 can correspond to a printing cloth cylinder. The pressure roller 3 can also correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com