Analysis method for fatigue of torsion beam welding assembly

An analysis method and torsion beam technology, applied in the analysis of materials, strength properties, measuring devices, etc., can solve problems such as low reliability, complex fatigue analysis, and imperfect analysis methods, saving project costs and reducing compression. Development cycle, the effect of accurate analysis results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

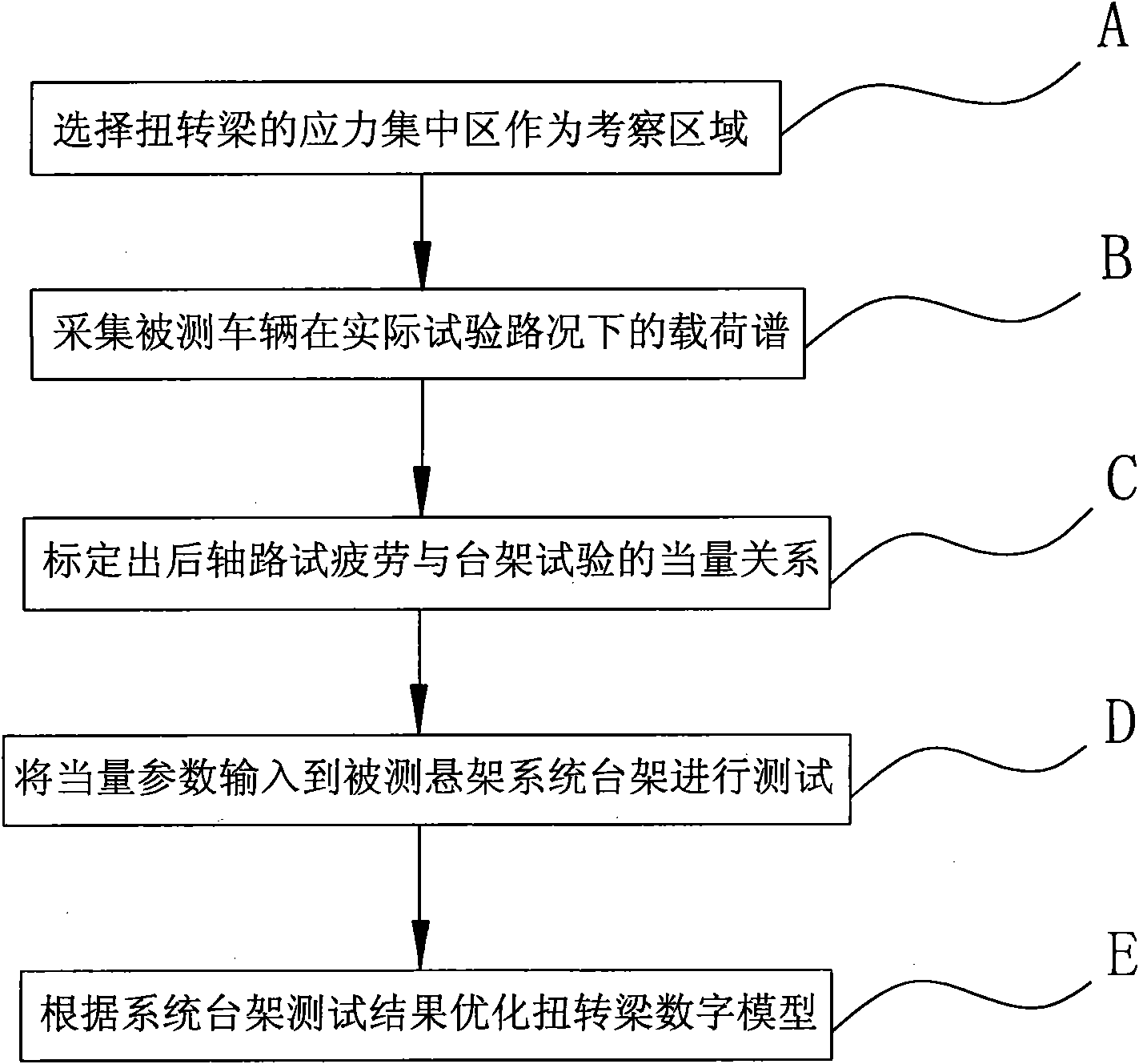

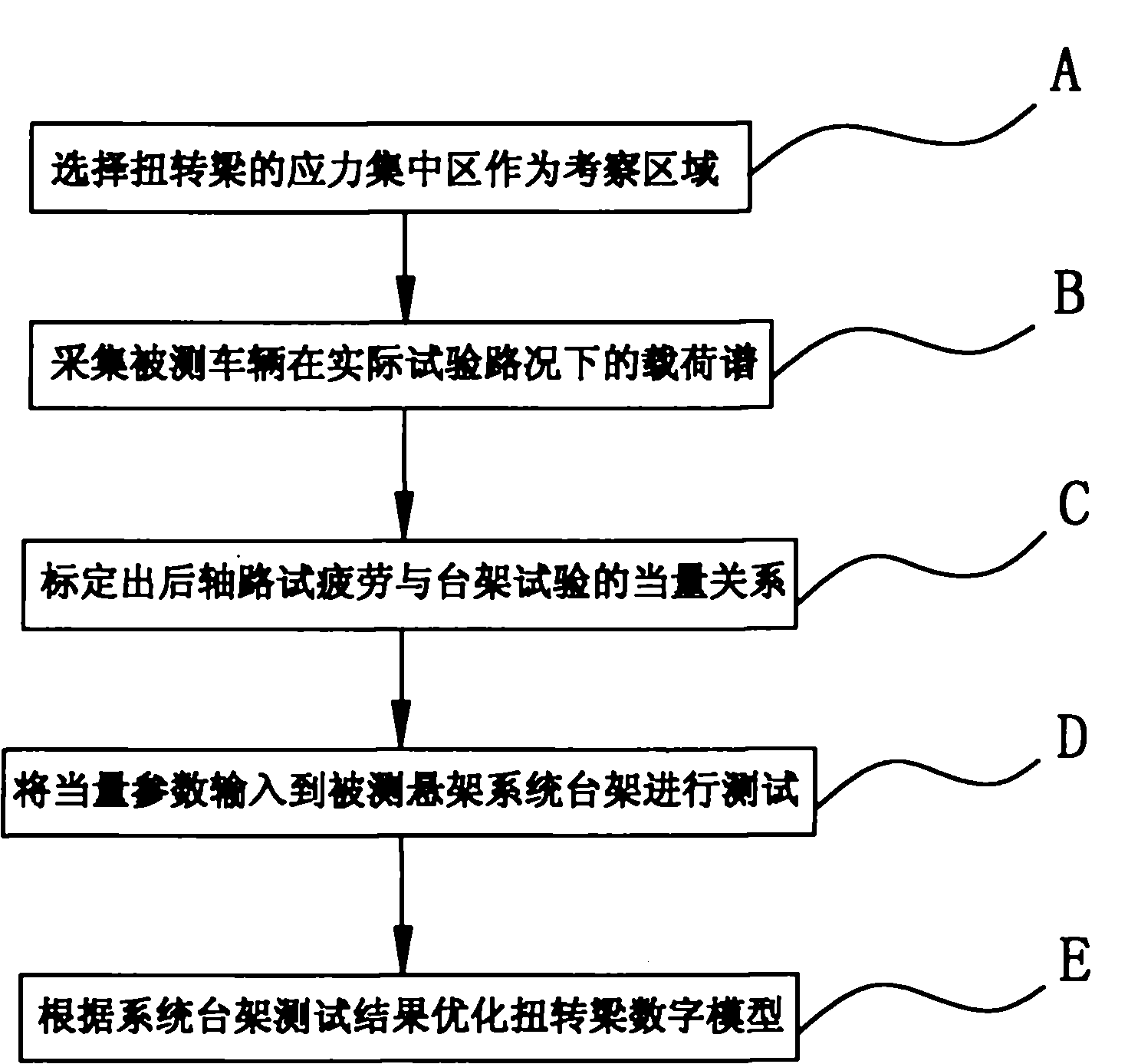

[0023] Such as figure 1 Shown, the analysis method of the fatigue degree of torsion beam welded assembly of the present invention comprises the steps:

[0024] A: Use the CAE analysis method to simulate the force of the torsion beam in the vehicle, and select the stress concentration area as the investigation area;

[0025] B: Paste the sensor strain gauge on the inspection area of the sample torsion beam, and then collect the load spectrum of the sample torsion beam of the tested vehicle under the actual test road conditions through the sensor strain gauge;

[0026] In step B, paste T-shaped strain rosettes on the tensile and compressive stress concentration area of the sample torsion beam, paste scissor rosettes on the torsional stress concentration area, and paste uniaxial strain gauges on the one-dimensional stress concentration area; the position of the strain gauges is left-right symmetrical, The resistance of the strain gauges is 350 ohms to improve the accuracy of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com