Continuous production equipment of vacuum glass

A vacuum glass and production equipment technology, applied in glass production, glass manufacturing equipment, glass molding, etc., can solve the problems of high energy consumption, high cost, low vacuum degree, etc., and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

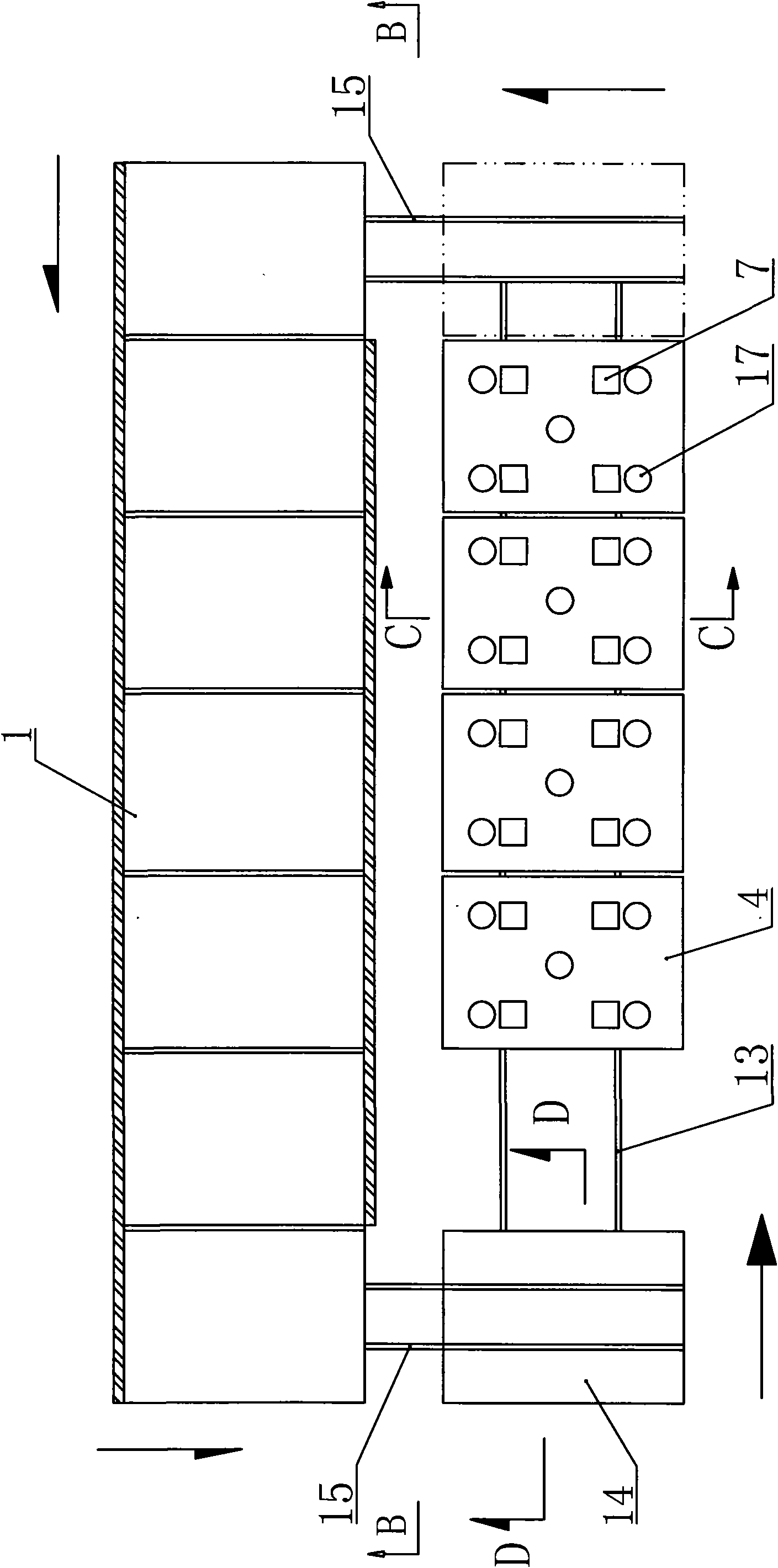

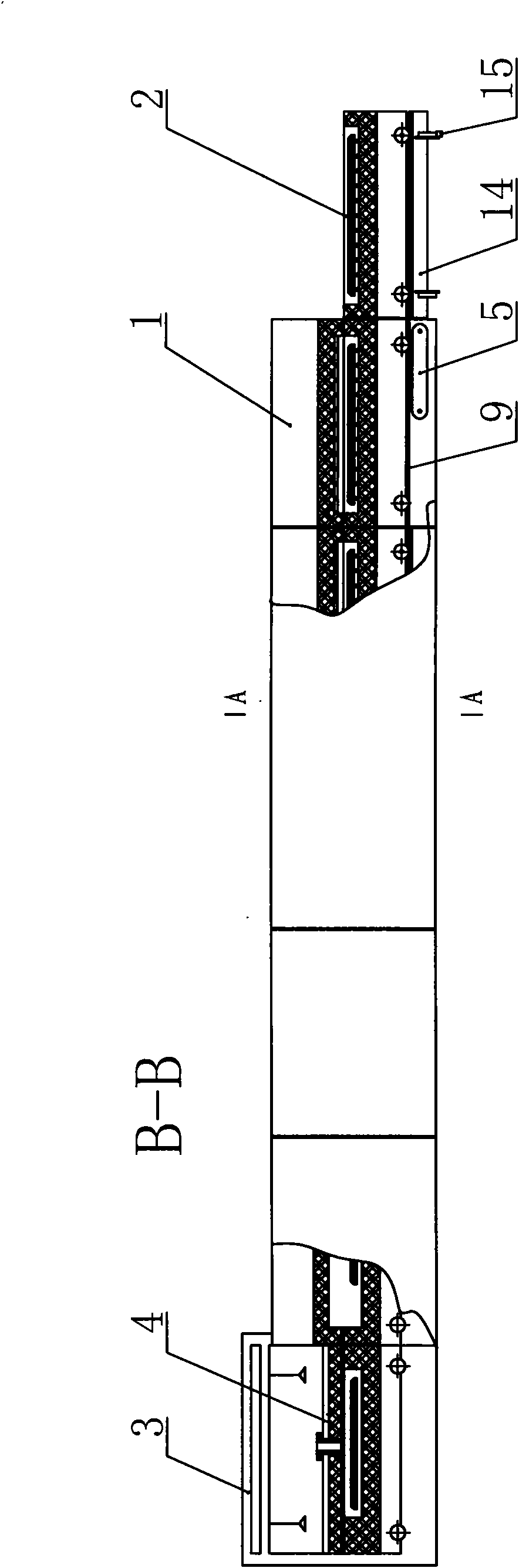

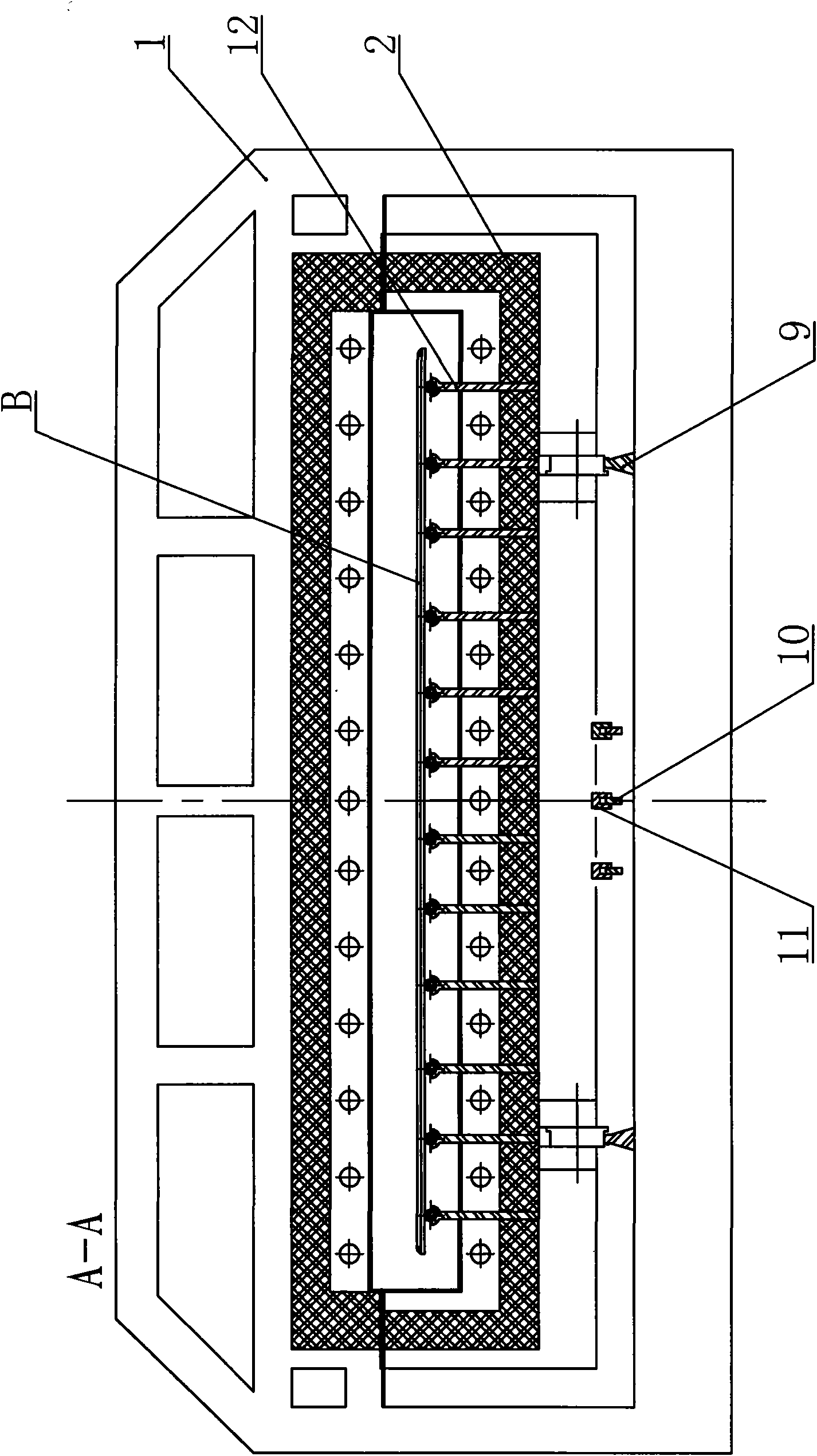

[0017] See Figure 1 ~ Figure 5 The present invention includes an edge-sealing furnace body 1, a heating box body 2, a vacuum exhaust sealing mechanism 7, and a glass taking-out and placing mechanism 8. Each heating box body 2 is provided with a bracket 12 for placing vacuum glass. The edge-sealing furnace body 1 is arranged in a row in sections, and the edge-sealing heater (in order to control the temperature in sections) is installed in the edge-sealing furnace body 1 of each section. A main rail 9 and a power supply bar 10 for supplying power to the heating box 2 are installed below, and a plurality of heating boxes 2 are equipped with rollers and arranged on the main rail 9 underneath; An auxiliary rail 13 parallel to the main rail 9 is provided on the outside of the edge banding furnace body 1, and a transition rail 15 is provided between the main rail 9 and the auxiliary rail 13 outside the two ends of the edge banding furnace body 1. The transition rail 15 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com