Insulation structure of LNG carrier cargo tank and construction method thereof

A technology for liquefied natural gas and transport ships, applied in the field of seams formed, can solve the problems of complex and laborious transport ships

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Some embodiments of the present invention will be described below with reference to the accompanying drawings.

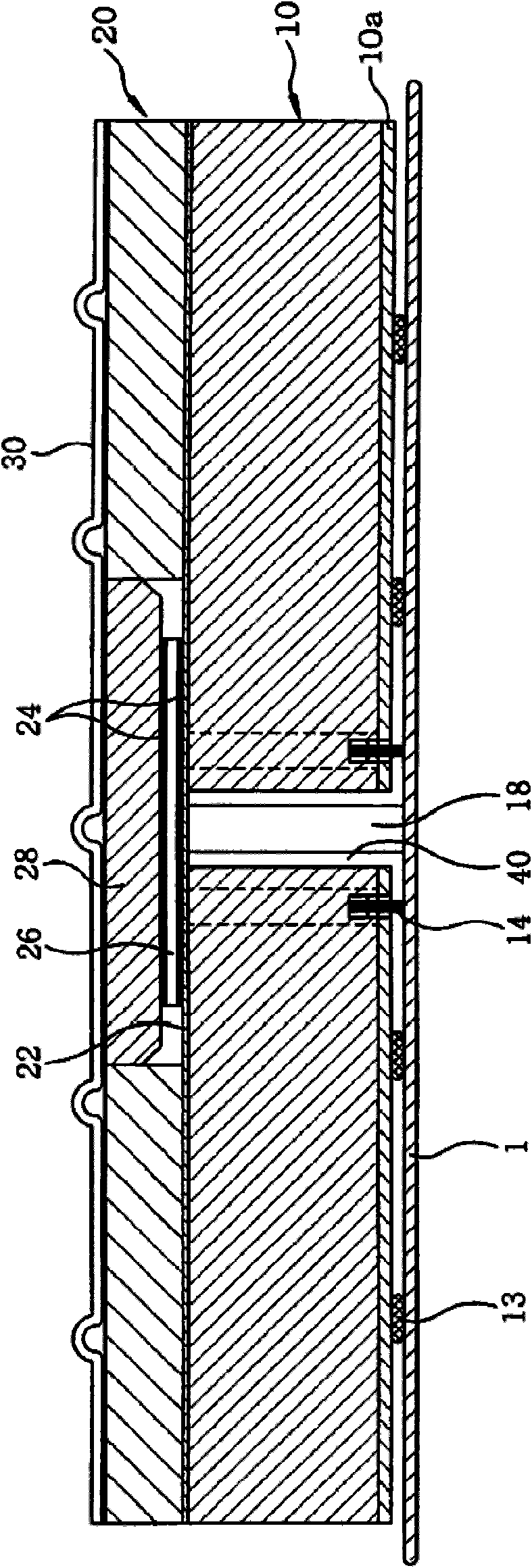

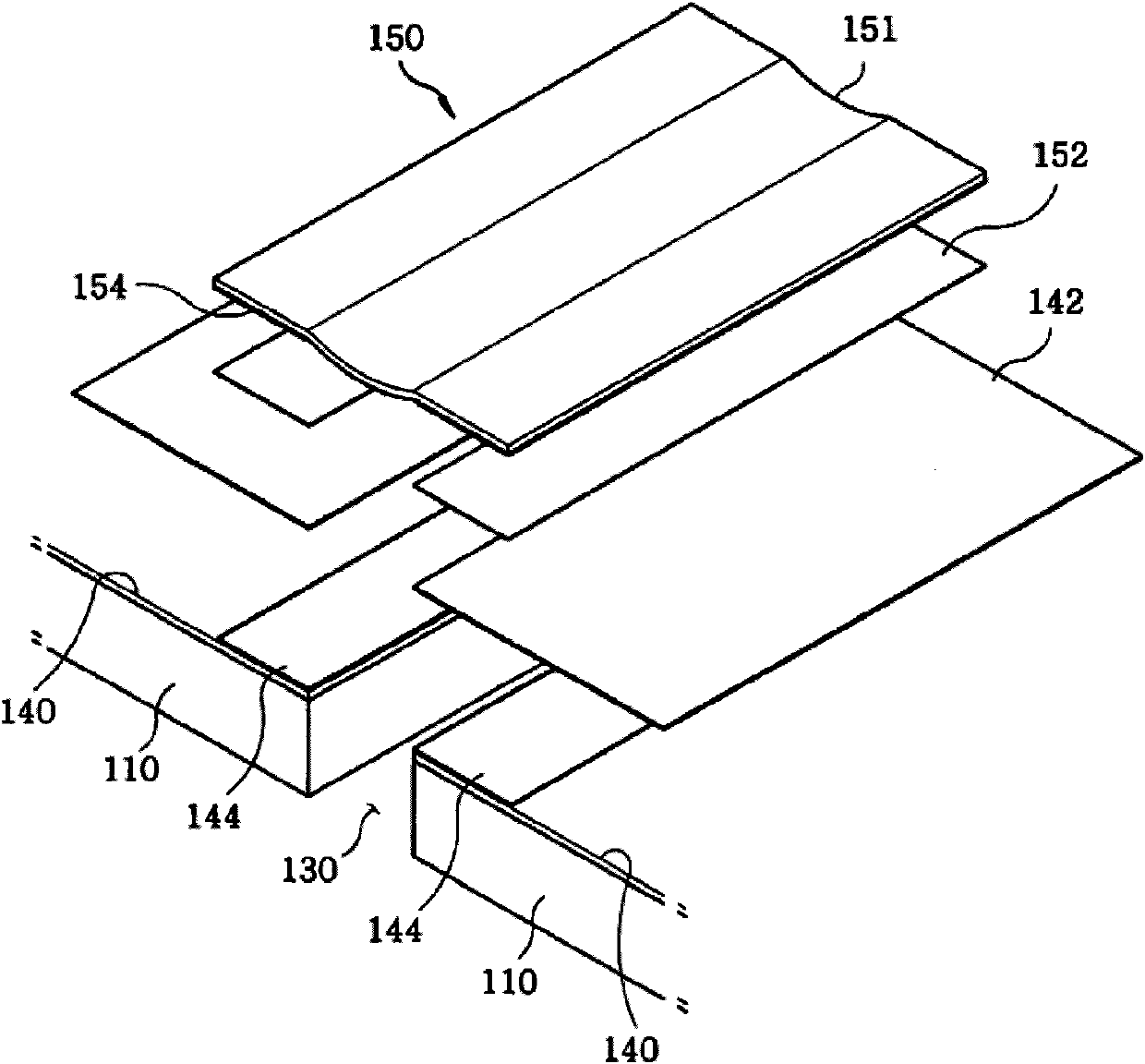

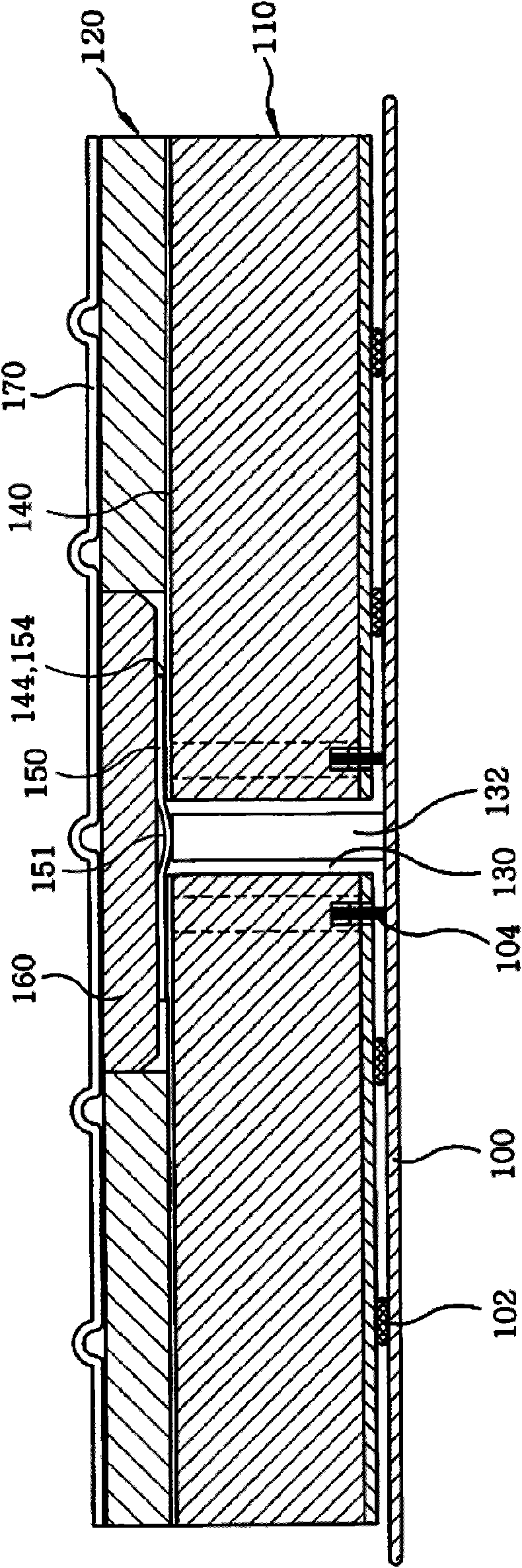

[0032] figure 2 is an exploded perspective view of a heat insulation structure of a cargo tank of an LNG carrier according to an embodiment of the present invention, image 3 is a sectional view of a heat insulation structure of a cargo hold of an LNG carrier according to an embodiment of the present invention.

[0033] exist figure 2 and image 3 In the structure of the cryogenic liquid cargo tank of the LNG carrier shown, the bottom heat insulation panel 110 is glued and fixed on the inner surface of the hull 100 of the LNG carrier with epoxy resin mastic 102 and stud bolts 104. A top insulation panel 120 is mounted on the bottom insulation panel 110 to form a part of the auxiliary barrier.

[0034] Here, a first metal sheet 140 is glued and installed between the bottom insulation panel 110 and the top insulation panel 120 .

[0035] The first metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com