Test device and test method thereof for automobile air-conditioning system

A technology of an automobile air-conditioning system and a testing method, which is applied in the field of testing devices of an automobile air-conditioning system, and can solve problems such as errors, large data costs, and large ring mold room costs, and achieve the effects of reduced product costs, minimum costs, and reduced pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

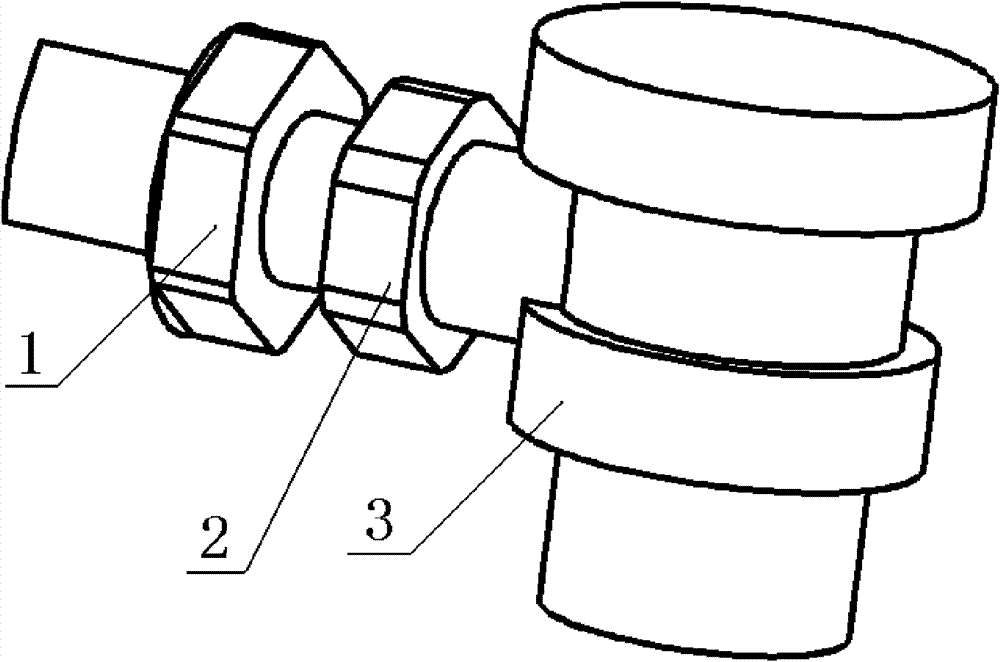

[0038] Depend on Figure 1-2 Combining the shown structures, it can be seen that the test device for the automotive air-conditioning system includes an intermediate connection tooling 2, one end of the intermediate connection tooling 2 is connected to one end of the pressure sensor 1, and the other end of the pressure sensor 1 is connected to the data recorder, and the data is recorded. The instrument collects the pressure and temperature signals of the automobile air-conditioning system through the pressure sensor 1 and the temperature probe; the other end of the intermediate connection tool 2 is connected to the fast charging connector 3 connected to the pipeline of the whole vehicle.

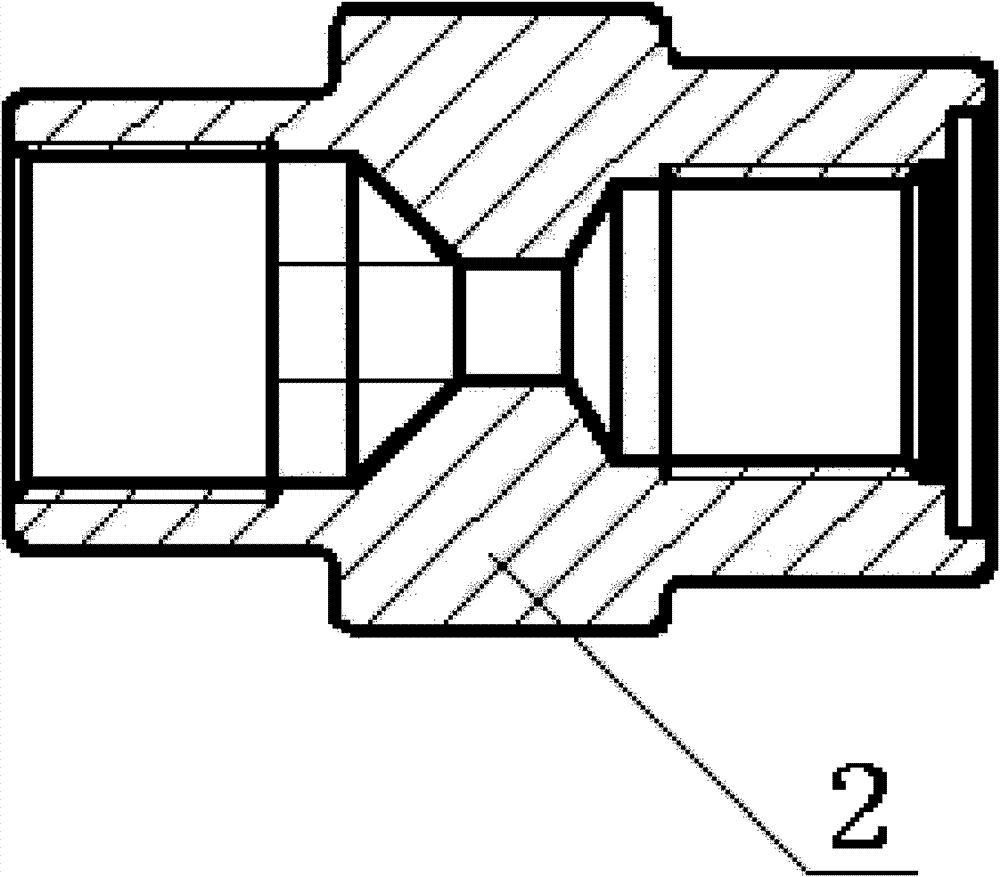

[0039] The intermediate connection tooling 2 is a "ten"-shaped structure with a through-hole structure in the axial direction, and the inner hole diameter at the middle position is smaller than the inner hole diameter at both ends; the inner hole diameter at the end where the intermediate conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com