Indirect evaporative chiller and mechanical refrigeration chiller combined cooling and air conditioning system

A technology of evaporative cold water and mechanical refrigeration, which is applied in air-conditioning systems, space heating and ventilation, household heating, etc. To solve problems such as limited air-conditioning, to achieve reasonable air-conditioning solutions, reasonable energy utilization, and high energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

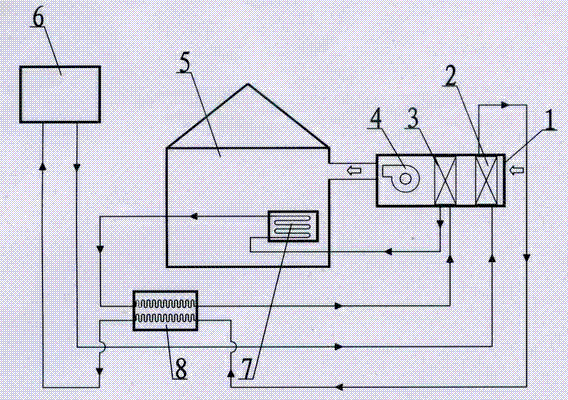

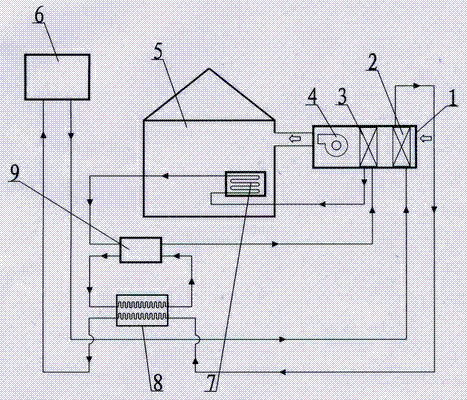

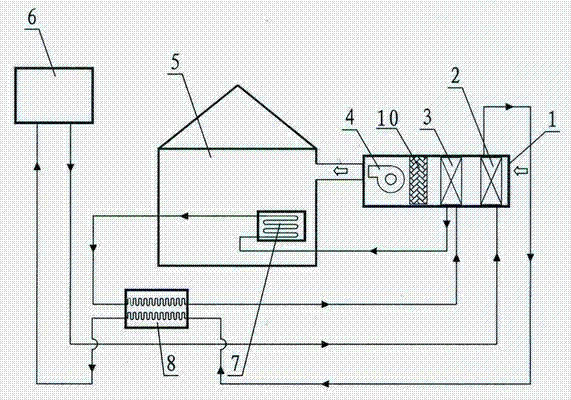

[0029] An indirect evaporative chiller and mechanical refrigeration chiller combined cooling and air conditioning system, such as figure 1 In the shown embodiment 1, in the air handler 1 casing having an air inlet and an air outlet, a primary surface heat exchanger 2, a secondary surface heat exchanger 3 and The air blower 4 and the outlet pipe of the indirect evaporative chiller 6 are connected to the water inlet of the primary surface heat exchanger 2 of the air handler 1, and the outlet pipe of the primary surface heat exchanger 2 is connected to the cooling of the traditional low-temperature chiller 8 The water inlet, the cooling water outlet of the traditional low-temperature chiller 8 is connected to the water inlet of the indirect evaporative chiller 6, the chilled water outlet of the traditional low-temperature chiller 8 is connected to the water inlet of the secondary surface heat exchanger 3, The outlet pipe of the secondary surface heat exchanger 3 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com