Novel method for designing super oleophobic surface structure

A design method, superoleophobic technology, applied in microstructure technology, microstructure device, nanostructure fabrication, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

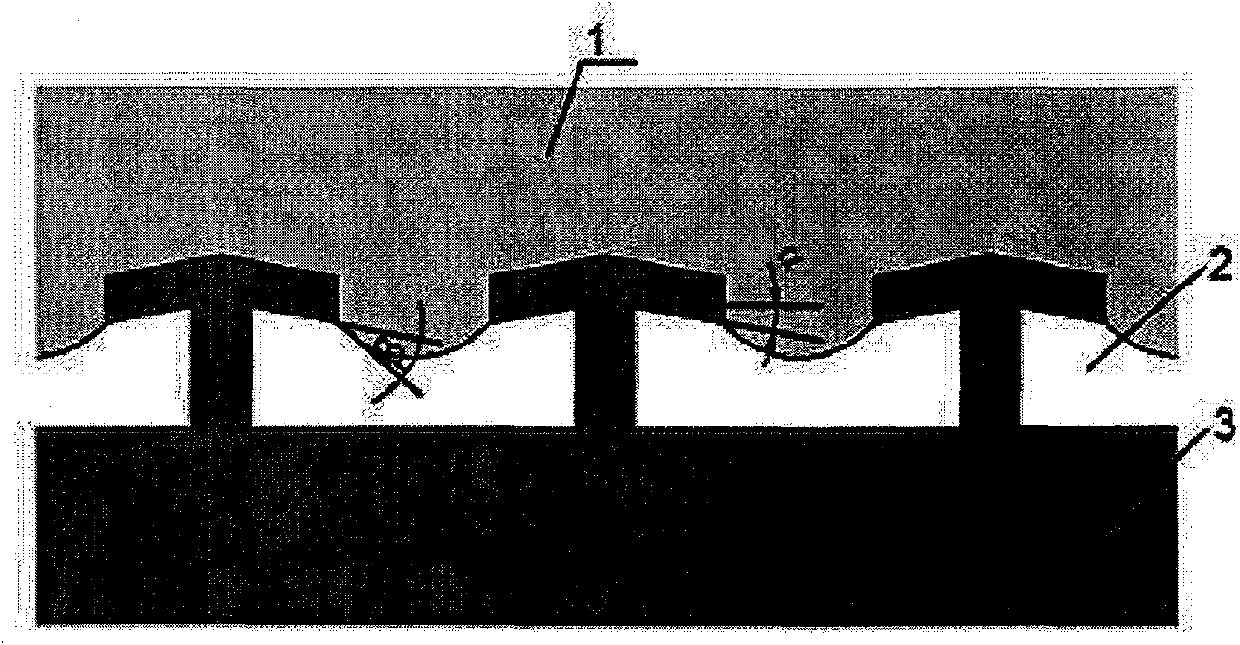

[0025] Embodiment 1 (square column form structure, section structure is figure 1 The structural form, environmental conditions and parameters are: P-P 0 =1kPa, θ=50°, γ=0.02N / m, θ C =140°, α=30°):

[0026] According to the Laplace formula, the curved surface radius of the liquid 1 inside the solid microstructure 3 is calculated, and the curved surface radius is: r=2γ / (P-P 0 )=2×0.02 / 1000=40 μm. Calculate the maximum period of the solid microstructure 3 according to the radius of the curved surface, and the maximum period of the microstructure is L max = 113 μm. At the same time, the protrusion ratio of the structure is calculated according to the Cassie calculation formula. f=(cosθ C +1) / (cosθ+1)=0.1424, ξ = f = 0.3774 .

[0027] Select the solid microstructure 3 whose structural period is L=1 μm, calculate the angle β formed between the interface formed by liquid 1 and air 2 and the vertical wall o...

Embodiment 2

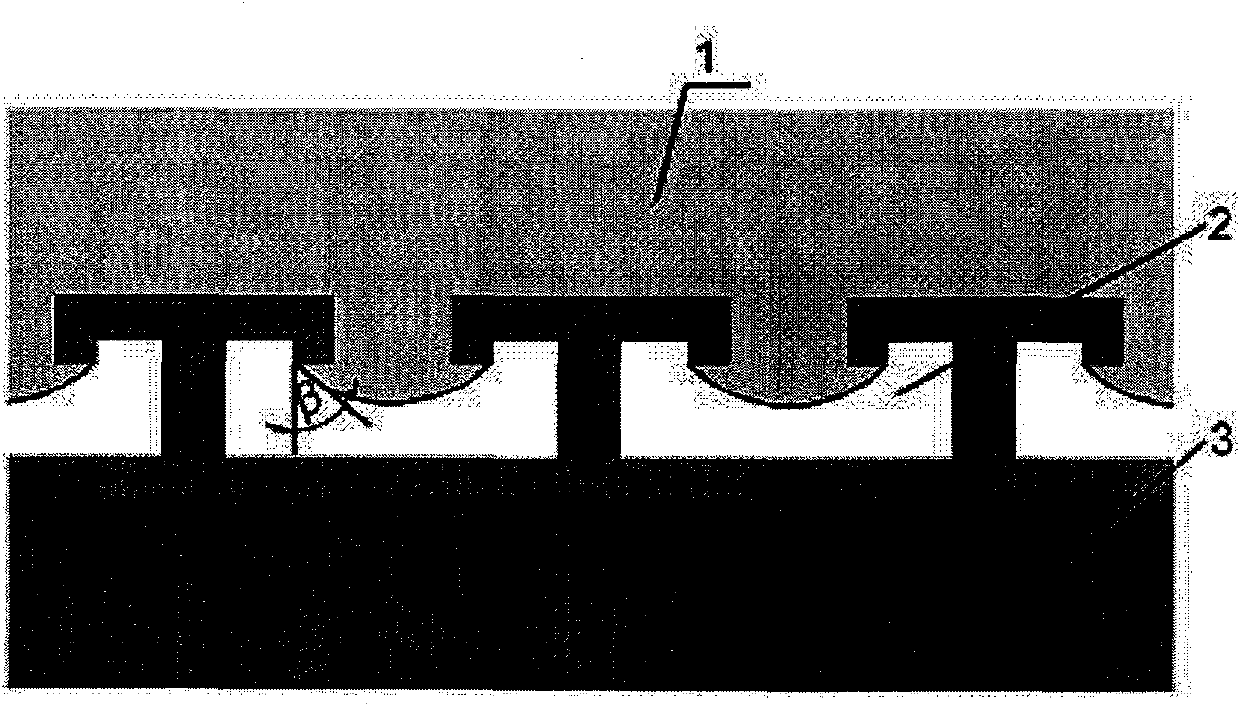

[0029] Embodiment 2 (square column form structure, section structure is figure 2 The structural form, environmental conditions and parameters are: P-P 0 =10kPa, θ=50°, γ=0.02N / m, θ C =140°):

[0030] Calculate the curved surface radius of the liquid surface of the liquid 1 in the solid microstructure 3 according to the Laplace formula, and the curved surface radius is: r=2γ / (P-P 0 )=2×0.02 / 1000=4 μm. Then calculate the maximum period of the structure according to the radius of the surface, and the maximum period of the structure is L max = 11.3 μm. At the same time, the protrusion ratio of the structure is calculated according to the Cassie calculation formula. f=(cosθ C +1) / (cosθ+1)=0.1424, ξ = f = 0.3774 .

[0031] Select a microstructure whose structural period is L=1 μm, and calculate the angle β formed between the interface formed by liquid 1 and air 2 and the wall of solid microstructure 3, β...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com