Coal gas washing, dedusting and purifying process

A purification process and gas washing technology, which can be used in gas dust removal, combustible gas purification, combustible gas purification/reconstruction, etc., can solve problems such as unclean purification and unclean dust removal, and achieve small maintenance workload, low investment and processing cost, The effect of improving the comprehensive utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

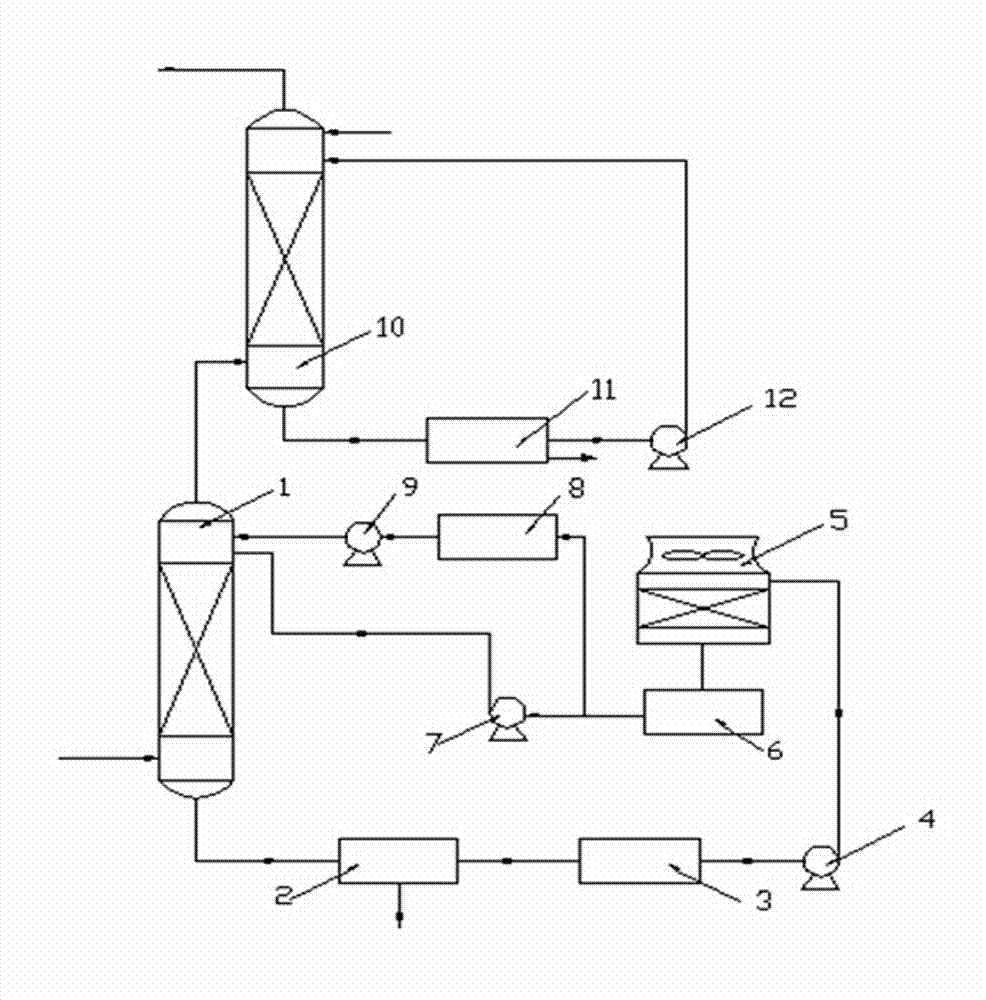

[0010] A coal gas washing and dust removal purification process, the process is achieved by the following steps: a. Pass the dust-laden gas into the dust-removing scrubber 1, make the dust-laden gas contact with the cooling water in the upper part of the dust-removing scrubber 1 for countercurrent washing, and then countercurrently contact with the purified water at the top of the dust-removing scrubber 1 for further washing and dedusting; b. The waste water after dedusting and washing flows into the sedimentation tank 2 through the bottom of the dedusting and washing tower 1 for precipitation, and the settled water flows into the hot water pool 3, and then flows into the cooling water tower 5 through the hot water pump 4 for cooling, and the cooled water enters the cooling water tank. The pool 6 is divided into two roads, one of which is driven into the upper part of the dust removal washing tower 1 by the cold water pump 7 for recycling, and the other road is purified by the ...

Embodiment 2

[0012] A coal gas washing and dust removal purification process, the process is achieved by the following steps: a. Pass the dust-laden gas into the dust-removing scrubber 1, make the dust-laden gas contact with the cooling water in the upper part of the dust-removing scrubber 1 for countercurrent washing, and then countercurrently contact with the purified water at the top of the dust-removing scrubber 1 for further washing and dedusting; b. The waste water after dedusting and washing flows into the sedimentation tank 2 through the bottom of the dedusting and washing tower 1 for precipitation, and the settled water flows into the hot water pool 3, and then flows into the cooling water tower 5 through the hot water pump 4 for cooling, and the cooled water enters the cooling water tank. The pool 6 is divided into two roads, one of which is driven into the upper part of the dust removal washing tower 1 by the cold water pump 7 for recycling, and the other road is purified by the ...

Embodiment 3

[0014] A coal gas washing and dust removal purification process, the process is achieved by the following steps: a. Pass the dust-laden gas into the dust-removing scrubber 1, make the dust-laden gas contact with the cooling water in the upper part of the dust-removing scrubber 1 for countercurrent washing, and then countercurrently contact with the purified water at the top of the dust-removing scrubber 1 for further washing and dedusting; b. The waste water after dedusting and washing flows into the sedimentation tank 2 through the bottom of the dedusting and washing tower 1 for precipitation, and the settled water flows into the hot water pool 3, and then flows into the cooling water tower 5 through the hot water pump 4 for cooling, and the cooled water enters the cooling water tank. The pool 6 is divided into two roads, one of which is driven into the upper part of the dust removal washing tower 1 by the cold water pump 7 for recycling, and the other road is purified by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com