Weft tension compensation device

A compensation device and tension technology, which is applied in textiles, textiles, papermaking, looms, etc., can solve the problems of large changes in the folding diameter of woven fabrics, weft yarn foaming, and large changes in weft yarn tension, and improve the unevenness of the cloth surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Further illustrate the present invention below in conjunction with accompanying drawing.

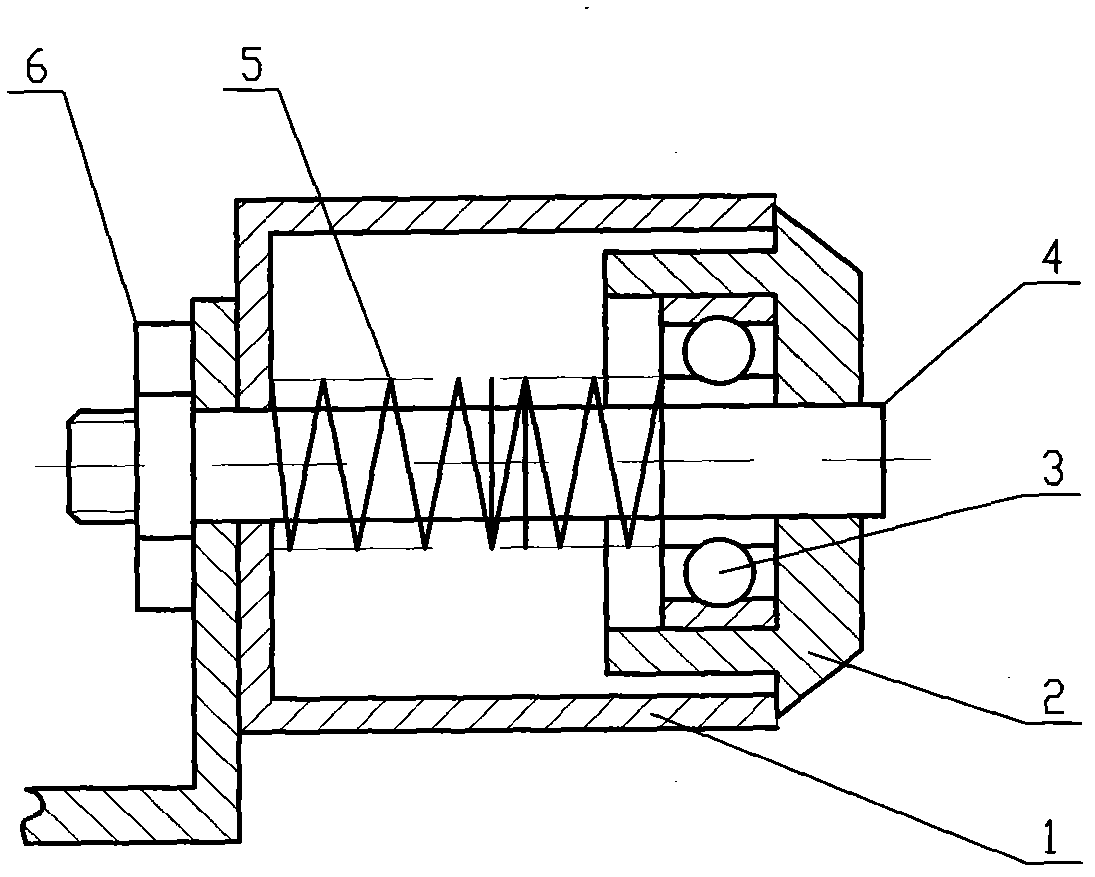

[0026] The structure of the original bobbin chuck is as follows: image 3 , including chuck seat 1, tube rotating chuck 2, bearing 3, chuck mandrel 4, chuck thrust spring 5 and mounting screw 6, chuck mandrel 4 is fixedly connected to chuck seat 1 through mounting screw 6 , the chuck mandrel 4 is equipped with a chuck thrust spring 5, and after the bobbin rotating chuck 2 is inserted into the chuck mandrel 4, it is pressed on the chuck seat 1, and the bobbin rotating chuck 2 and the chuck mandrel 4 A bearing 3 is arranged between them, and the bearing 3 is pressed in the bobbin rotary chuck 2 by the chuck thrust spring 5 .

[0027] The weft tension compensation device of the present invention is to be transformed on the basis of the above-mentioned original device, and its structure is as follows: Figure 4 , specifically: increase the number of bearings 3 in the bobbin rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com