Automatic blanking device for coating fluid used in production process of fiberglass cloth

A technology of automatic cutting and production process, which is applied to the device and coating of the surface coating liquid, which can solve the problems of uneven cutting and complicated operation, and achieve uniform cutting process, quality assurance and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

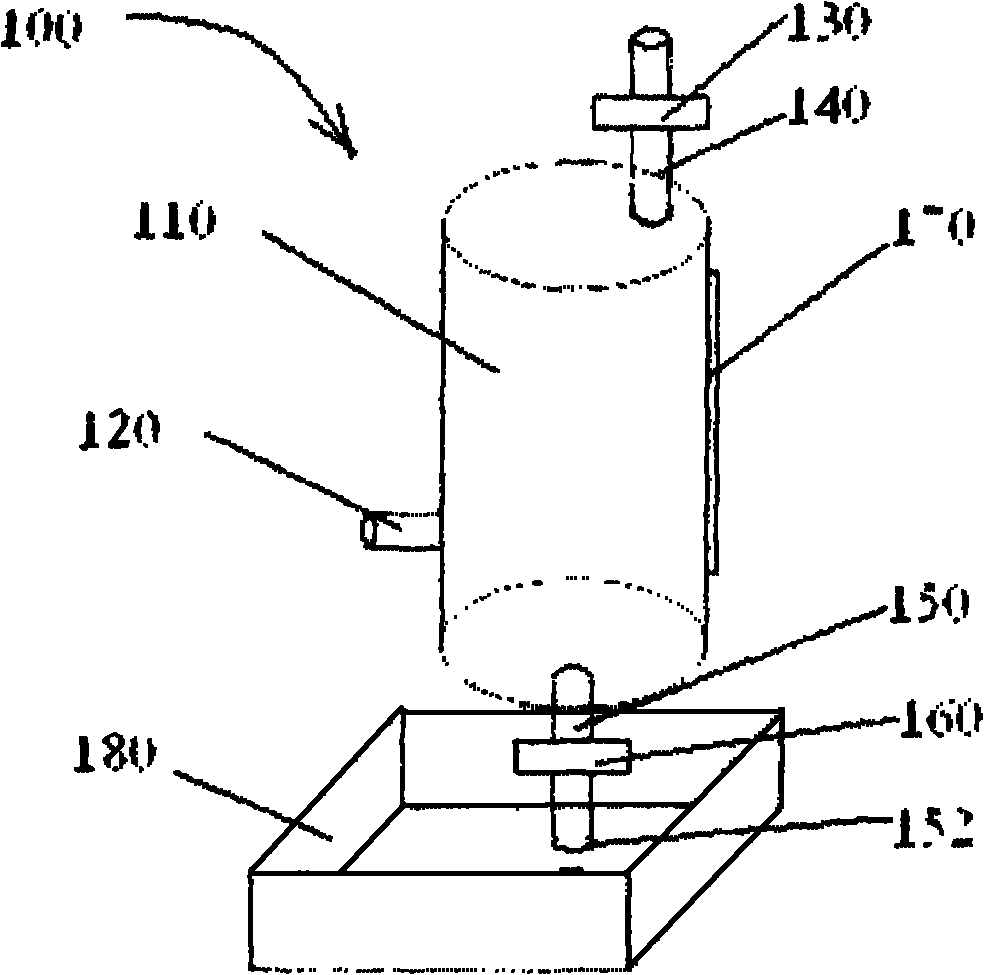

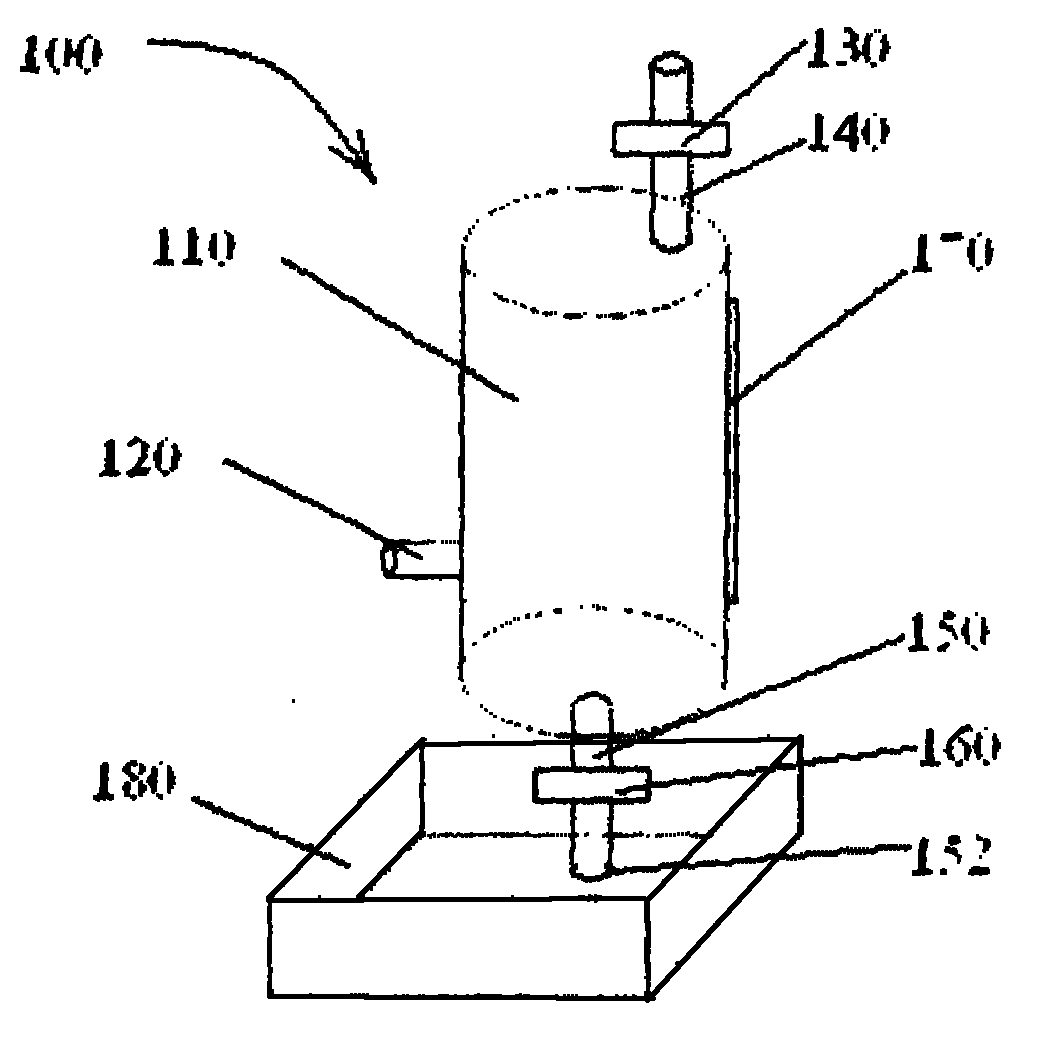

[0016] see figure 1 As shown, the coating liquid automatic feeding device 100 according to the present invention includes a main body 110 in which is provided a housing chamber (not shown) for holding the coating liquid. A raw material receiving port 120 for receiving coating liquid injection is provided on one side of the housing chamber. An air discharge pipe 130 is provided at the upper end of the receiving cavity, and an air discharge valve 140 is also provided thereon. A conveying pipe 150 is arranged at the lower part of the containing chamber, and the coating solution contained therein is discharged through this pipe. Moreover, an on-off valve 160 is provided on the delivery pipe 150 to close the delivery pipe 150 when necessary.

[0017] Further, in order to observe the storage condition of the raw material coating liquid in the sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com