Method for automatically testing repeater based on instrument control

An automated test and repeater technology, applied in transmission monitoring, transmitter monitoring, radio relay systems, etc., can solve the problems of incomplete utilization of instrument resources, heavy workload, technical obstacles, etc., to facilitate tracking management and The effect of controlling, improving production efficiency, and reducing employment standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

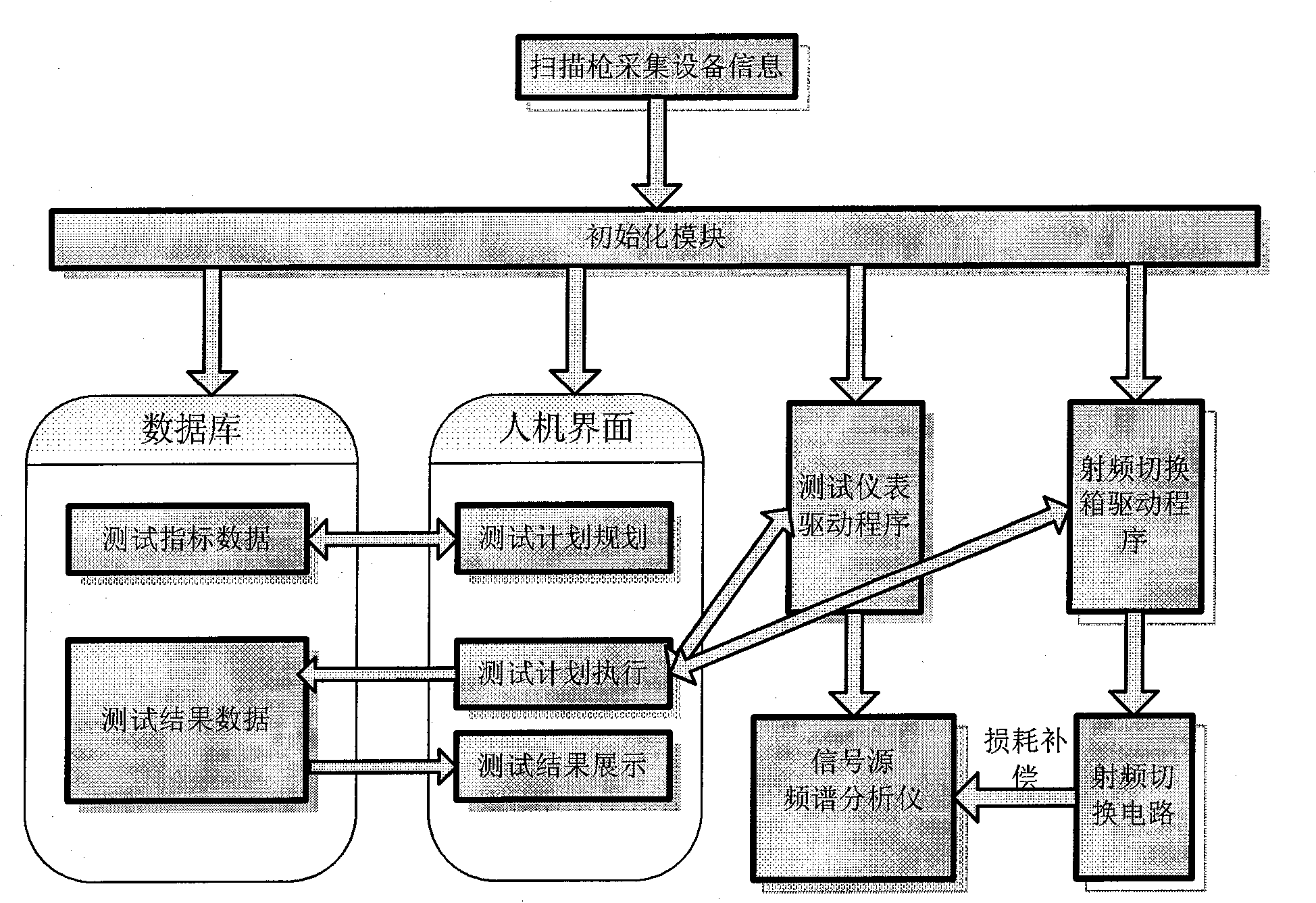

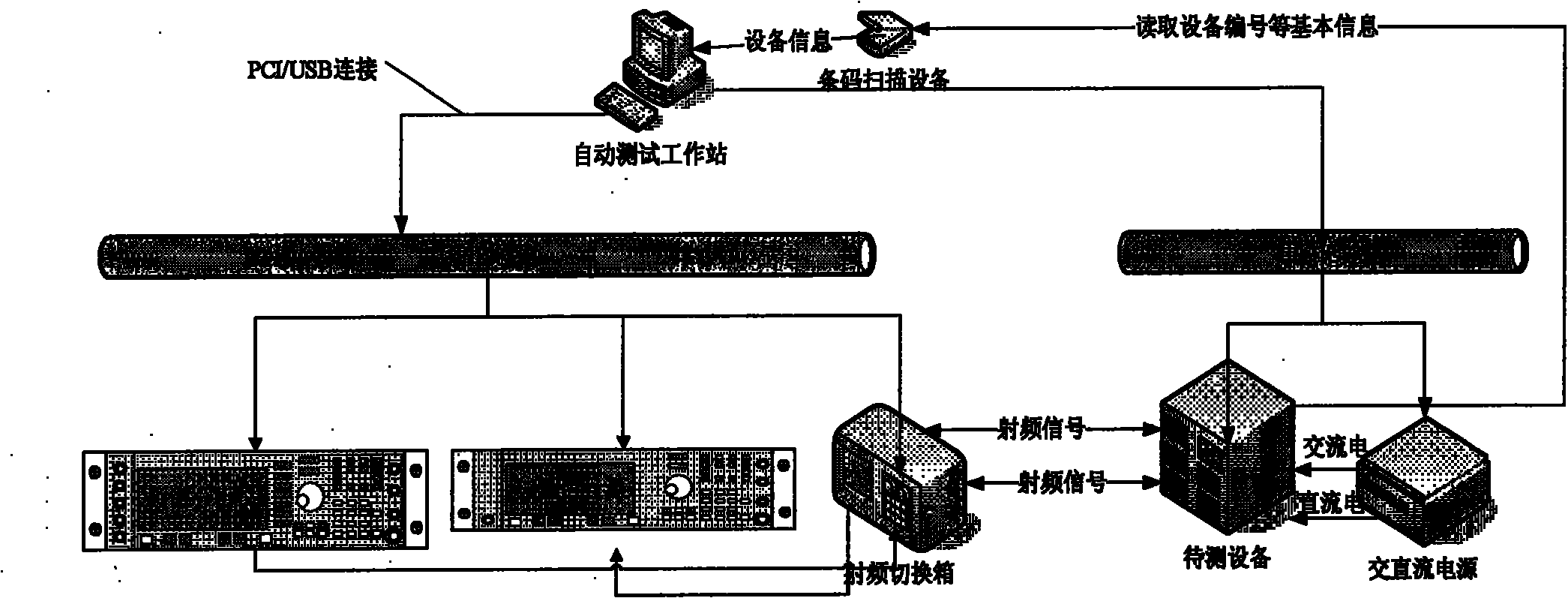

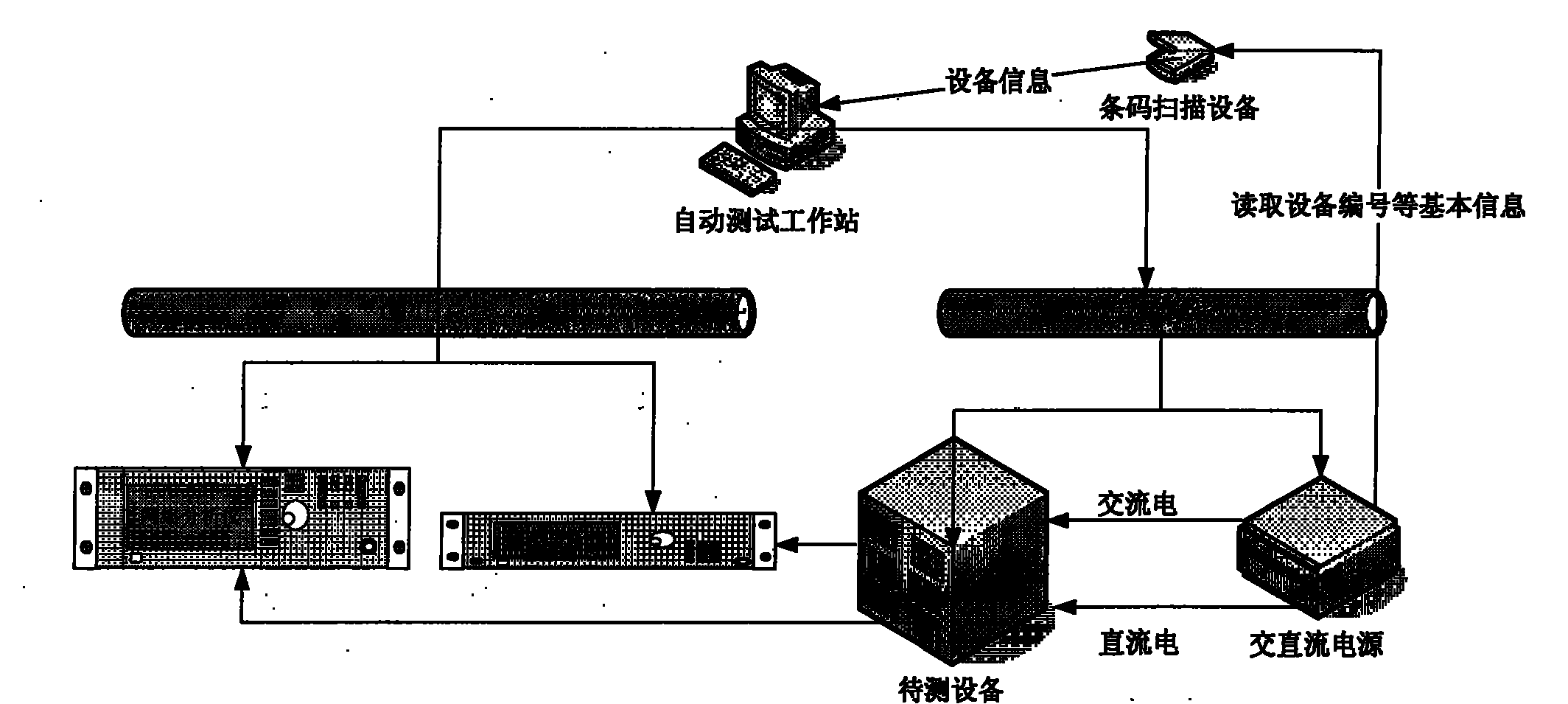

Method used

Image

Examples

Embodiment Construction

[0059] The repeater automatic test method based on instrument control, it includes the instrument automatic calibration process, which is implemented sequentially according to the following steps:

[0060] (1) Initialize the signal source and power meter;

[0061] (2) Power meter zeroing and calibration;

[0062] (3) User access signal source and power meter;

[0063] (4) switch the interface box;

[0064] (5) The frequency cycle reads the power, calculates the loss and saves it in the file;

[0065] (6) Complete path judgment, if yes, end; if not, return to step (2).

[0066] The present invention also includes a test plan customization process, which is implemented sequentially according to the following steps:

[0067] (1) Create a new test plan;

[0068] (2) Select existing test items into the test plan;

[0069] (3) Modify the parameter value of the test item;

[0070] (4) Judgment that the test plan is completed, if yes, save the test plan; if not, return to step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com