Full-automatic accurate adjustment device for track plate of ballastless track of rapid transit railway

A ballastless track and fine-tuning equipment technology, applied in tracks, track laying, track maintenance, etc., can solve the problems of error-prone, difficult to achieve movement accuracy, high labor intensity, etc., and achieve a reasonable adjustment structure design, fast and reliable connection mode , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

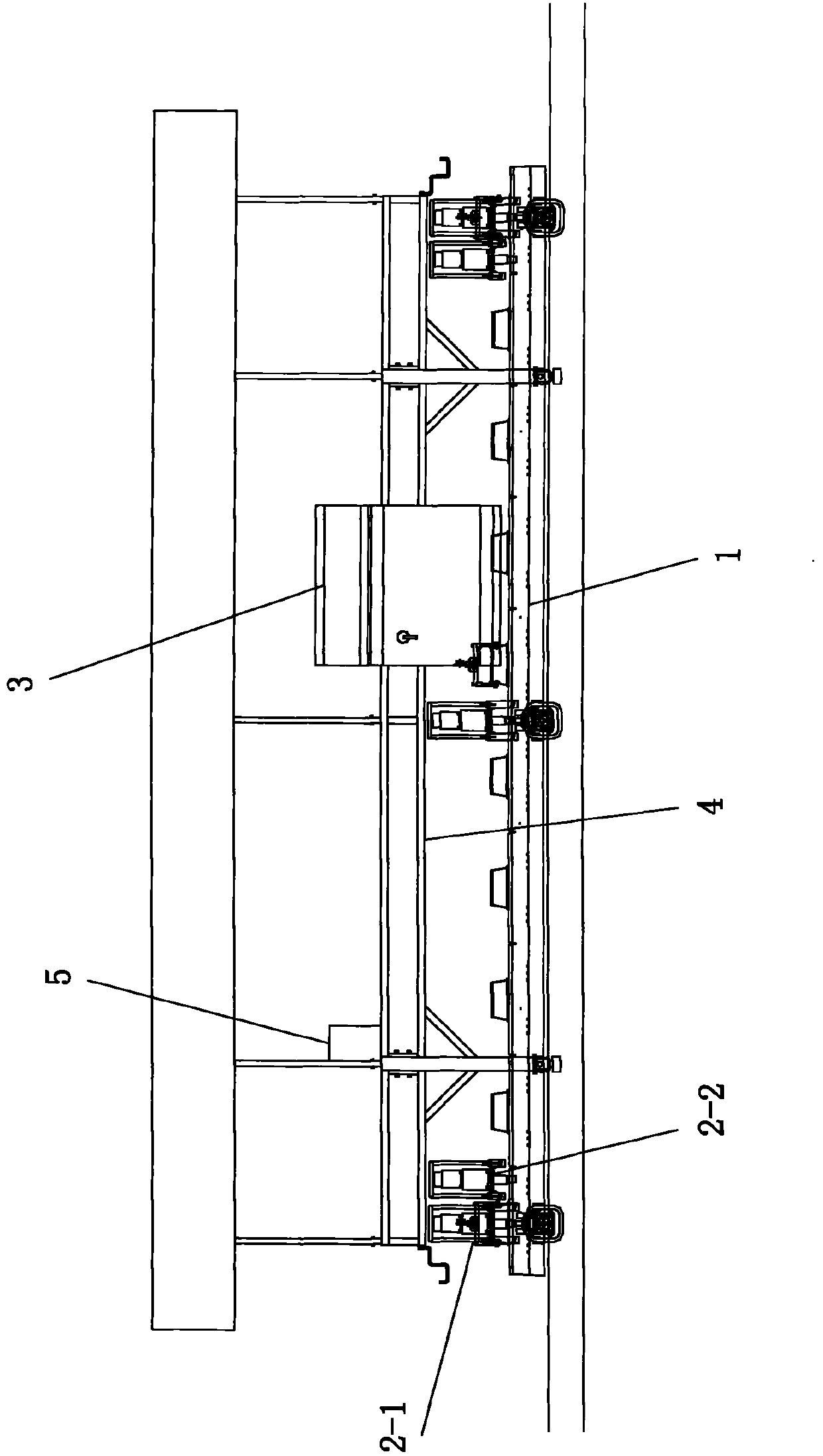

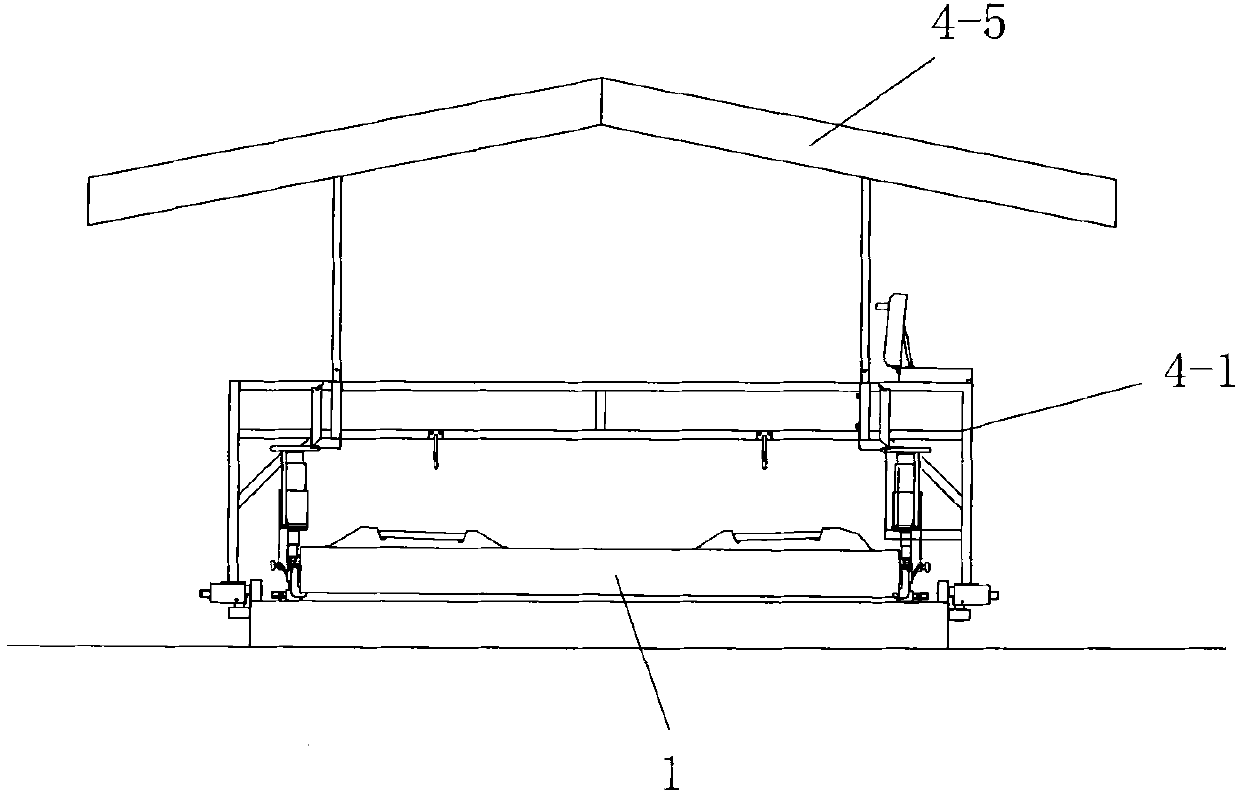

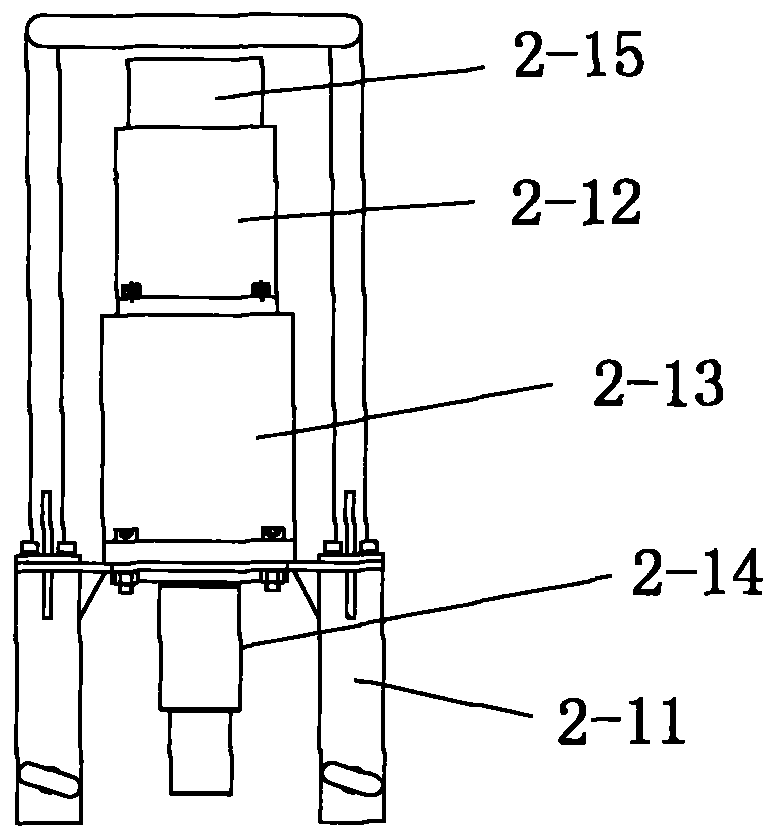

[0053] Such as figure 1 , figure 2 A full-automatic fine-tuning device for the track slab of a high-speed railway ballastless track shown, including adjusting a plurality of fine-tuning claws installed on the track slab 1 to be fine-tuned and positioned, so as to accurately adjust the installation position of the track slab 1 Positioning multiple adjusters, according to the deviation value between the actual position of the track plate 1 measured by the measuring device (6) and the design position, synchronously controls the adjustment direction and adjustment amount of multiple said adjusters and drives the control Platform 3, the power distribution box 5 connected with the console 3 and the mobile frame 4 that can move back and forth along the track plate 1, a plurality of the adjusters and the console 3 are all installed on the mobile frame 4, a plurality of The adjusters are all electrically connected with the console 3 . The fine adjustment claw includes a support body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com