Grading mechanism of surface mounted type electronic component testing and sorting machine

A technology for electronic components, testing and sorting machines, applied in sorting and other directions, can solve the problems affecting product sorting quality, expensive spline shafts, unstable operation, etc., to achieve simple structure, small inertia, improve quality and The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

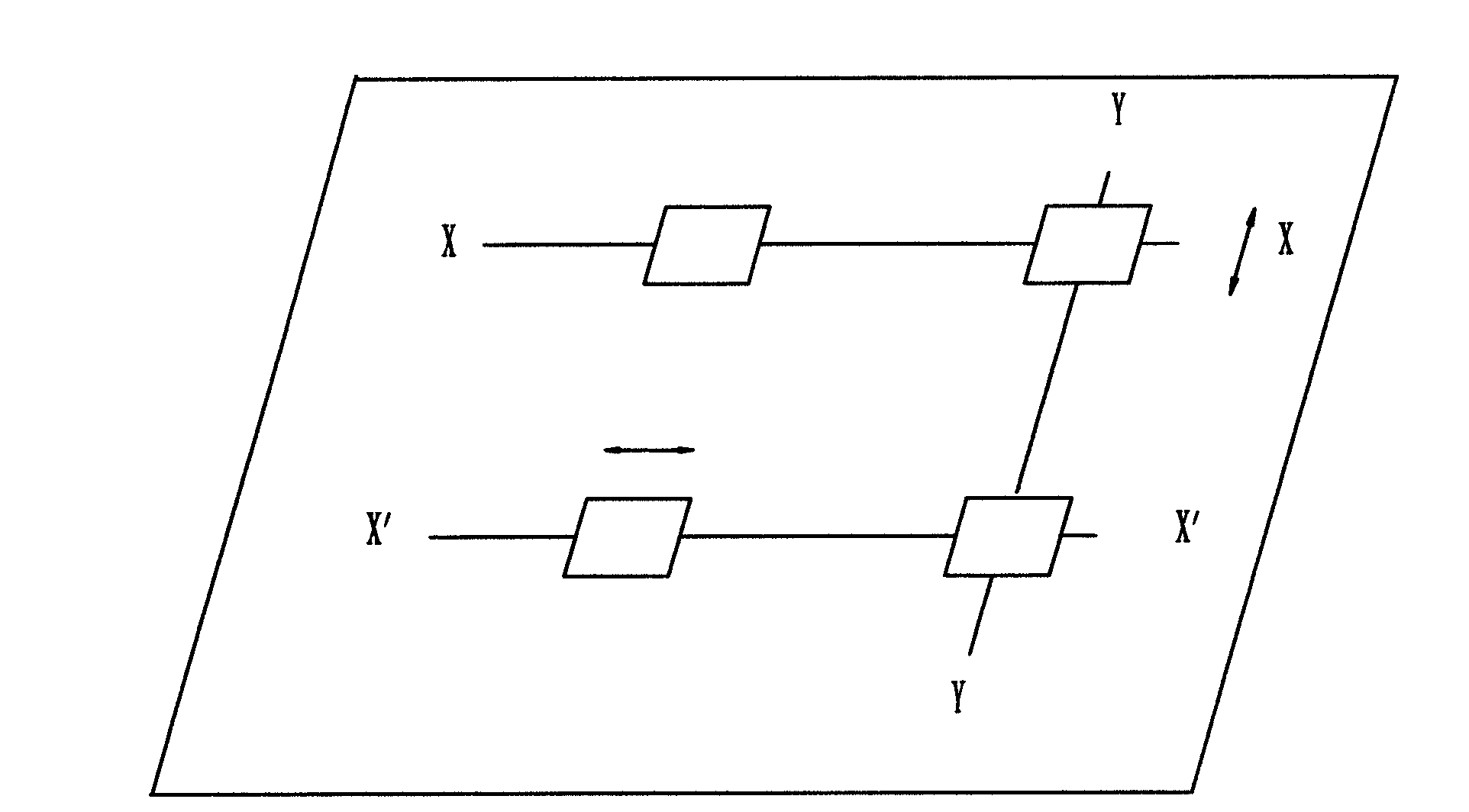

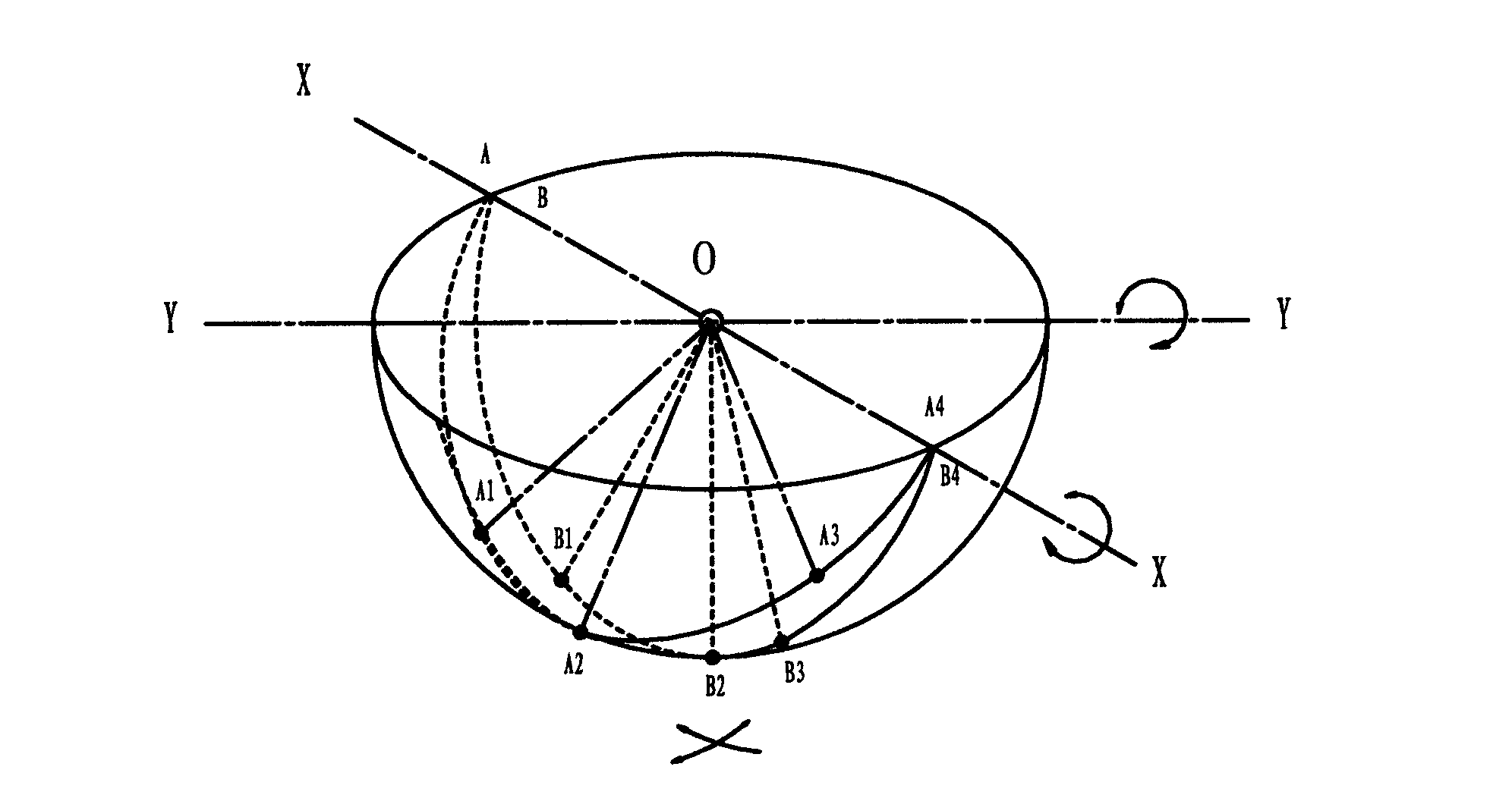

[0028] An embodiment of the present invention provides a sorting mechanism for a surface-mounted electronic component testing and sorting machine, which is used in a fully automatic surface-mounted electronic component testing and sorting machine in the field of semiconductor manufacturing, which includes a first timing belt conveyor device, a second synchronous belt transmission device that is in transmission connection with the first synchronous belt transmission device, a material distribution device that is in transmission connection with the first synchronous belt transmission device or the second synchronous belt transmission device, and a The material receiving device below the material distribution device is used to receive electronic devices, and the movement area of the material distribution device is the inner wall of the material receiving device. The utility model has the advantages of low cost, simple structure, large number of bins, high speed and stable operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com