Motor vehicle power train

A technology for motor vehicles and drive trains, which is applied to motor vehicles, electric vehicles, hybrid vehicles, etc., and can solve problems such as expensive, complex structures, and difficult manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

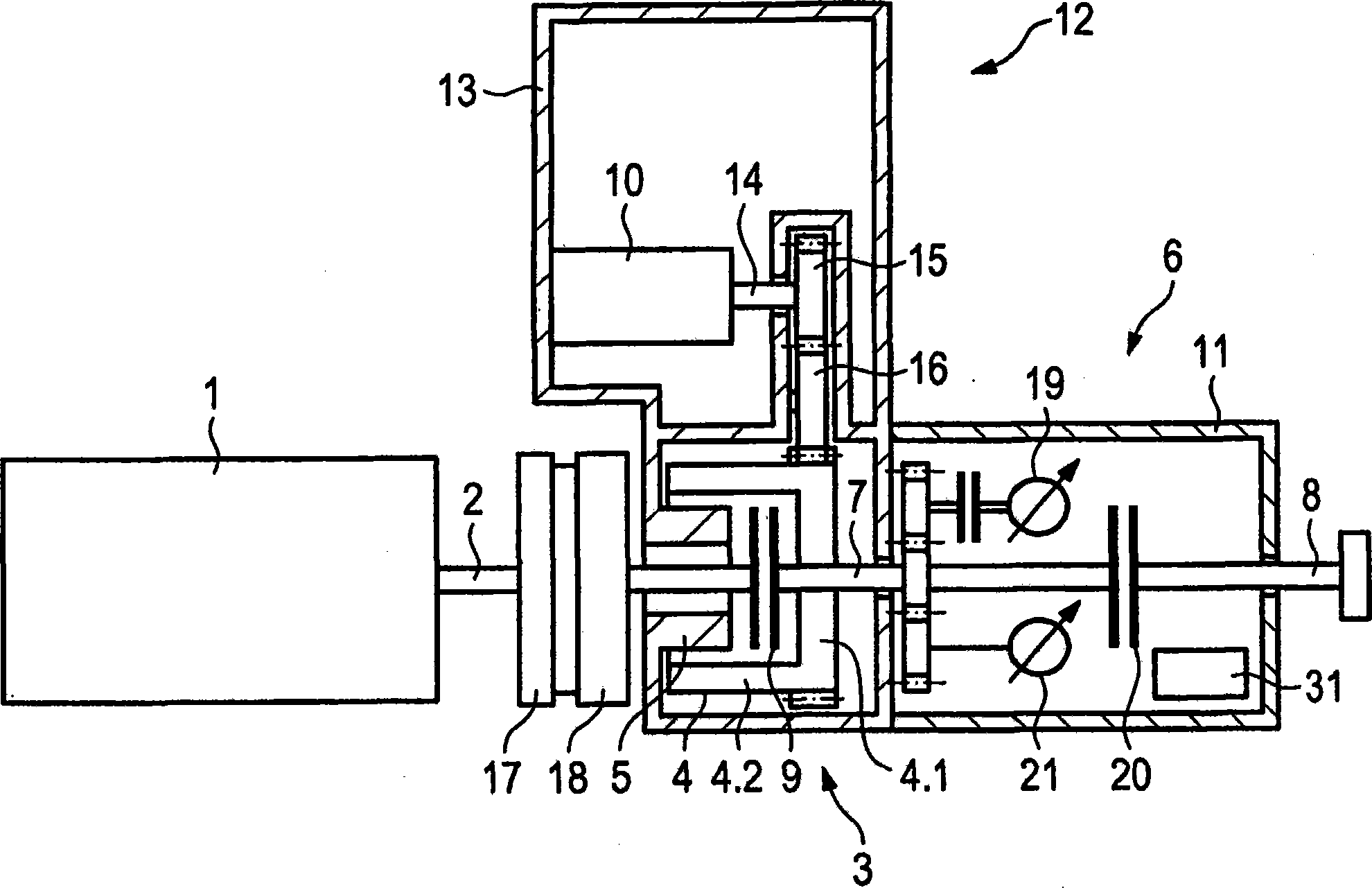

[0024] figure 1A schematic diagram of a first embodiment of a motor vehicle drive train according to the invention is shown. Here, viewed in the direction of power transmission, the following components are connected in series: the main drive motor 1, the driven shaft 2, the flywheel 17, the torsional vibration damper 18, the first separation clutch 9, the electric motor 3 and the first and The gearbox 6 of the second pump 19 , 21 , the second separating clutch 20 and the gearbox output shaft 8 . Currently, the main drive engine 1 is designed as an internal combustion engine and drives the gearbox input shaft 7, the gearbox output shaft 8 of the gearbox 6 and is drive-connected to the gearbox output shaft 8 in a first operating state when the first separating clutch 9 is engaged. A cardan shaft, not shown, drives the drive wheels of the vehicle, also not shown (first power branch). At the same time, the drive power is transmitted via the rotor 4 of the electric motor 3 , whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com