Reversing contactor

A contactor and contact bridge technology, applied in relays, electromagnetic relays, non-polar relays, etc., can solve problems affecting the use of electrical products, low electromagnetic utilization, large magnetic loss, etc., to achieve quality improvement, small magnetic flux leakage, and magnetic low loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

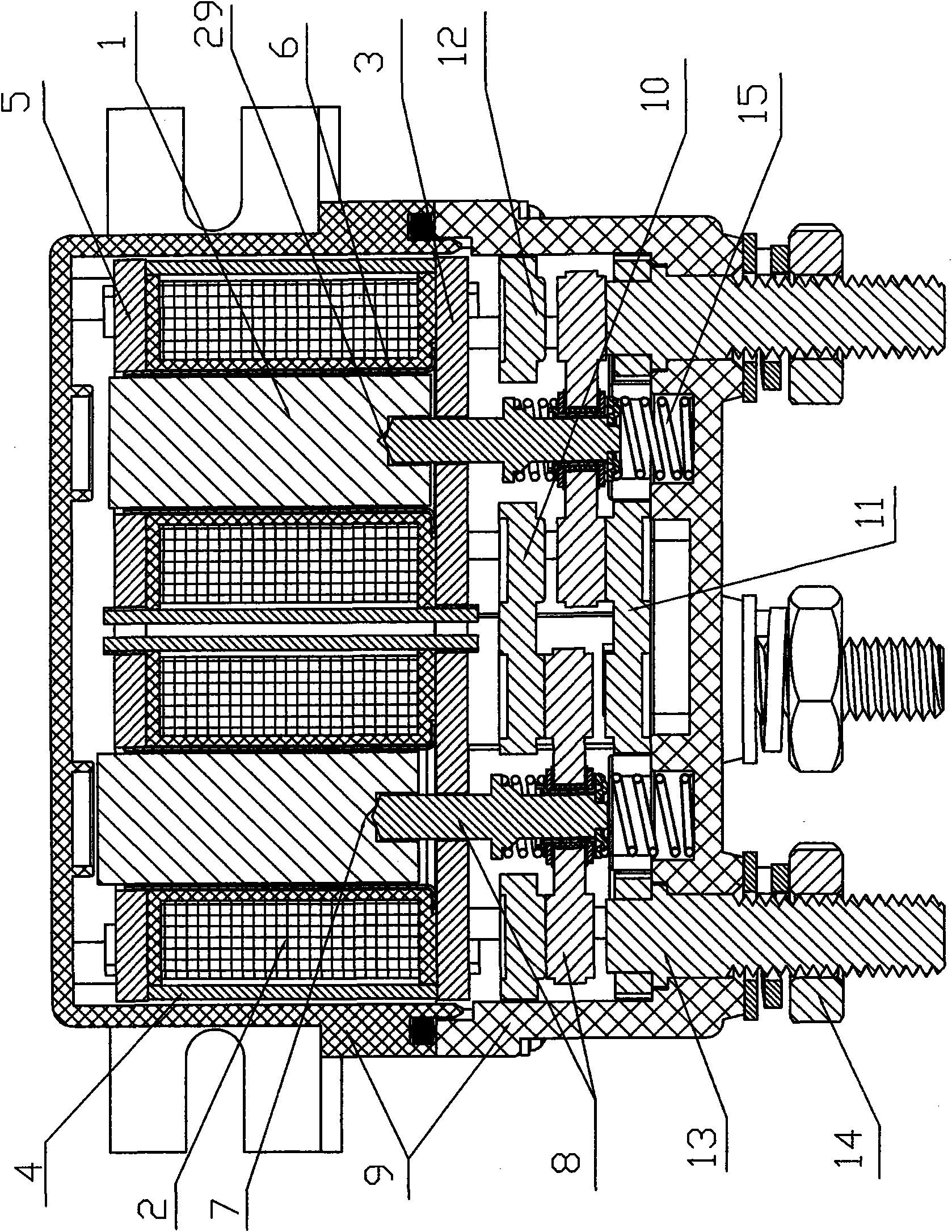

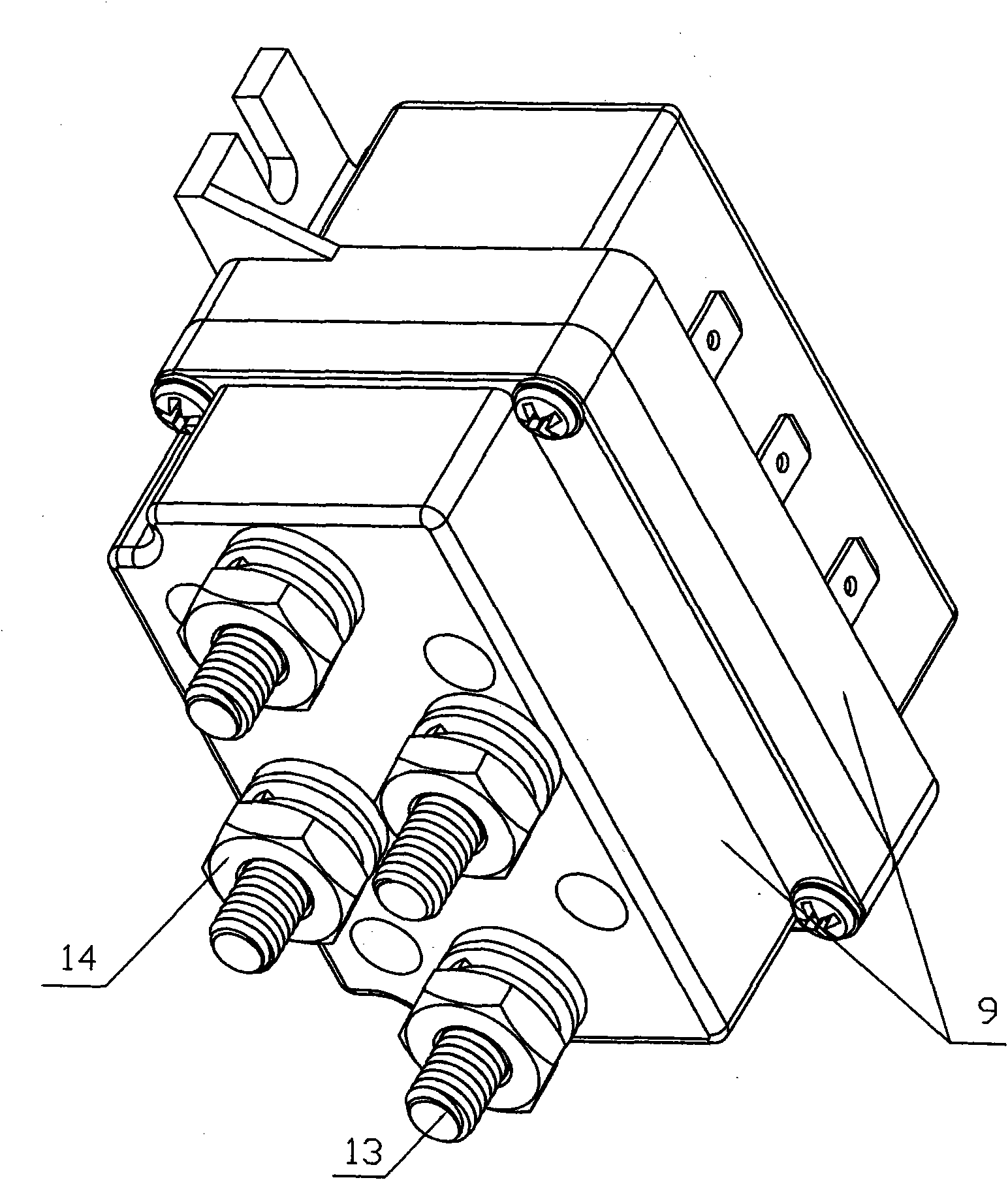

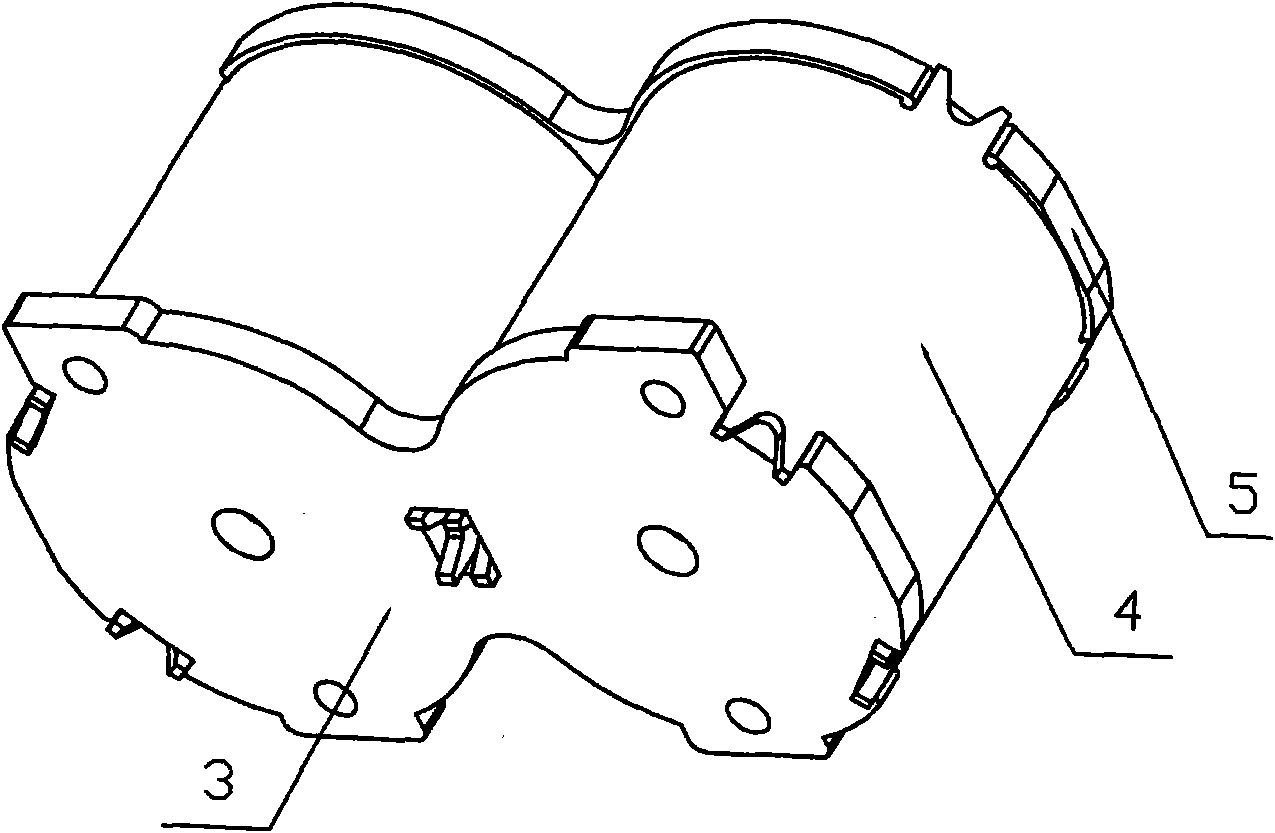

[0011] refer to Figure 1 to Figure 3 It can be seen that the reversing contactor of the present invention consists of electromagnetic components (for two sets), movable contact bridge member 8 (for two sets), upper contact bridge 10, lower contact bridge 11, curved contact bridge 12 (for two sets), curved Bridge studs 13 (and nuts 14, four sets), return springs 15 (two sets, installed corresponding to the movable contact bridge components), housing 9, wherein the electromagnetic components include iron core 1, coil 2 and lower The magnetically conductive plate 3 is equipped with a magnetically permeable outer ring 4 on the periphery of the coil 1, and the magnetically permeable outer ring 4 and the lower magnetically permeable plate 3 surround the coil 2 and the iron core 1 with a "U" shaped square frame (such as figure 1 shown), and an upper magnetically conductive plate 5 is also installed above the coil 1.

[0012] Wherein, the coil 2 is installed in the coil frame 6; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com