Full automatic tread abutting machine and abutting method thereof

A laminating machine and fully automatic technology, applied in the field of rubber machinery, can solve the problems of low retreading production efficiency, low processing precision, and waste of materials, and achieve the effects of reducing tire retreading costs, improving work efficiency, and reducing precision control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

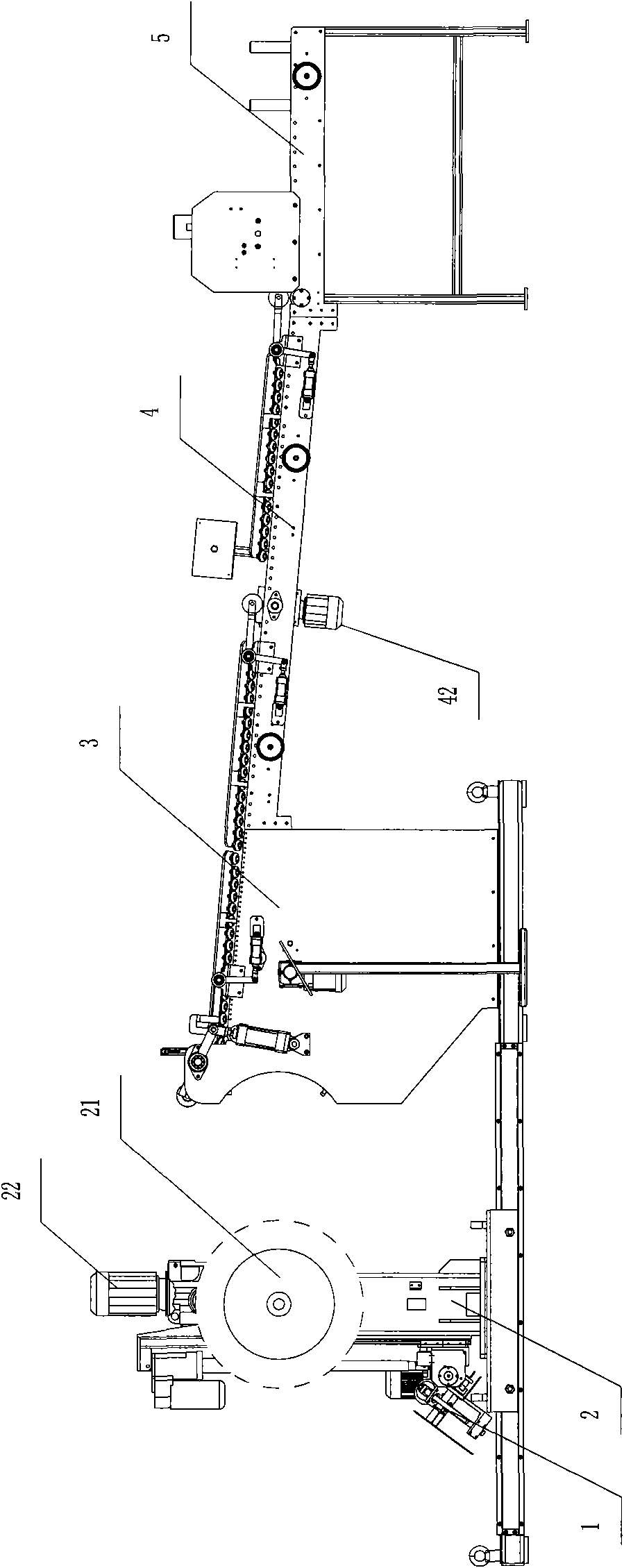

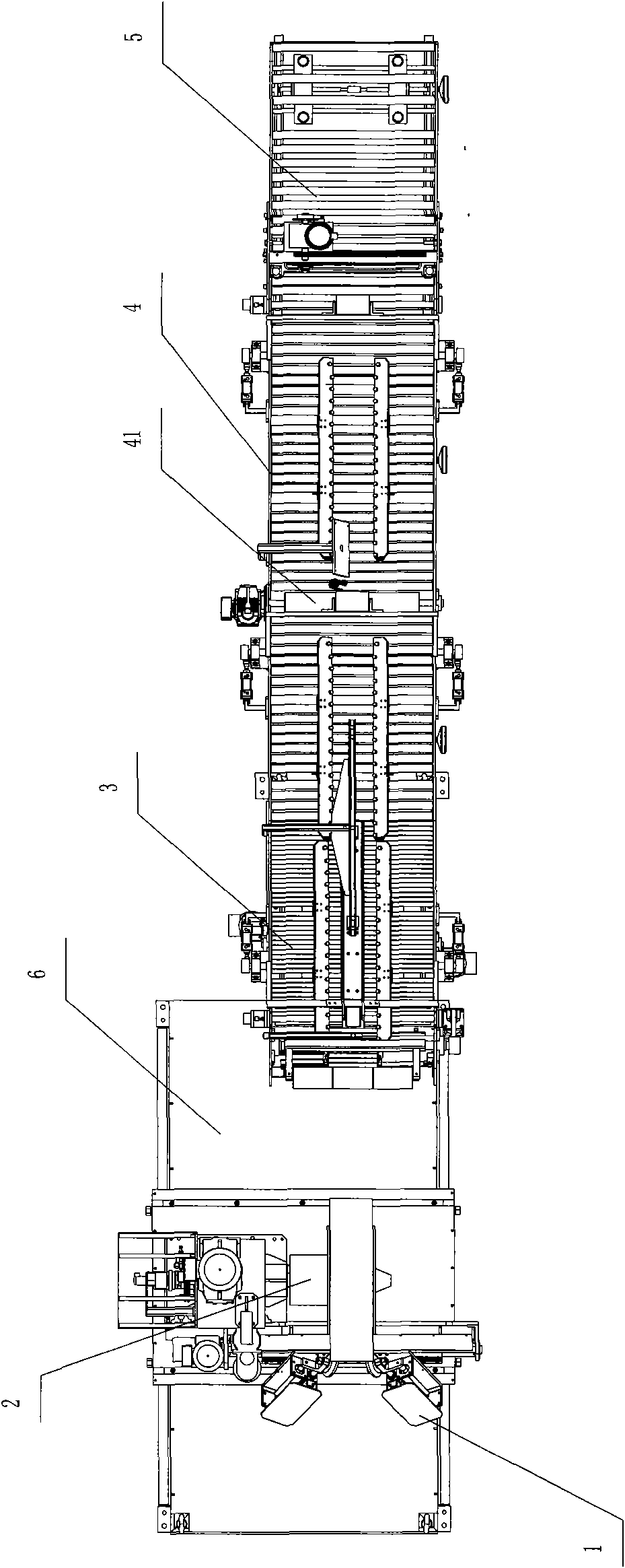

[0069] Example 1, such as figure 1 and figure 2 As shown, the fully automatic tread laminating machine includes a main machine 2, on which a rim 21 driven by a motor and a reducer 22 and carrying the tire to be retreaded is arranged.

[0070] The main machine 2 is slidably connected to the rails on both sides of the base 6 , and a separating and closing roller device 1 for pressing the tread rubber is also arranged on one side of the main machine 2 .

[0071] A cutting device 5, a rear conveying device 4 and a front conveying device 3 are sequentially connected along the tread rubber conveying direction.

[0072] The main driving roller 41 in the rear conveying device 4 is driven to rotate by the motor and the reducer 42, thereby providing the power for the forward conveying of the tread rubber.

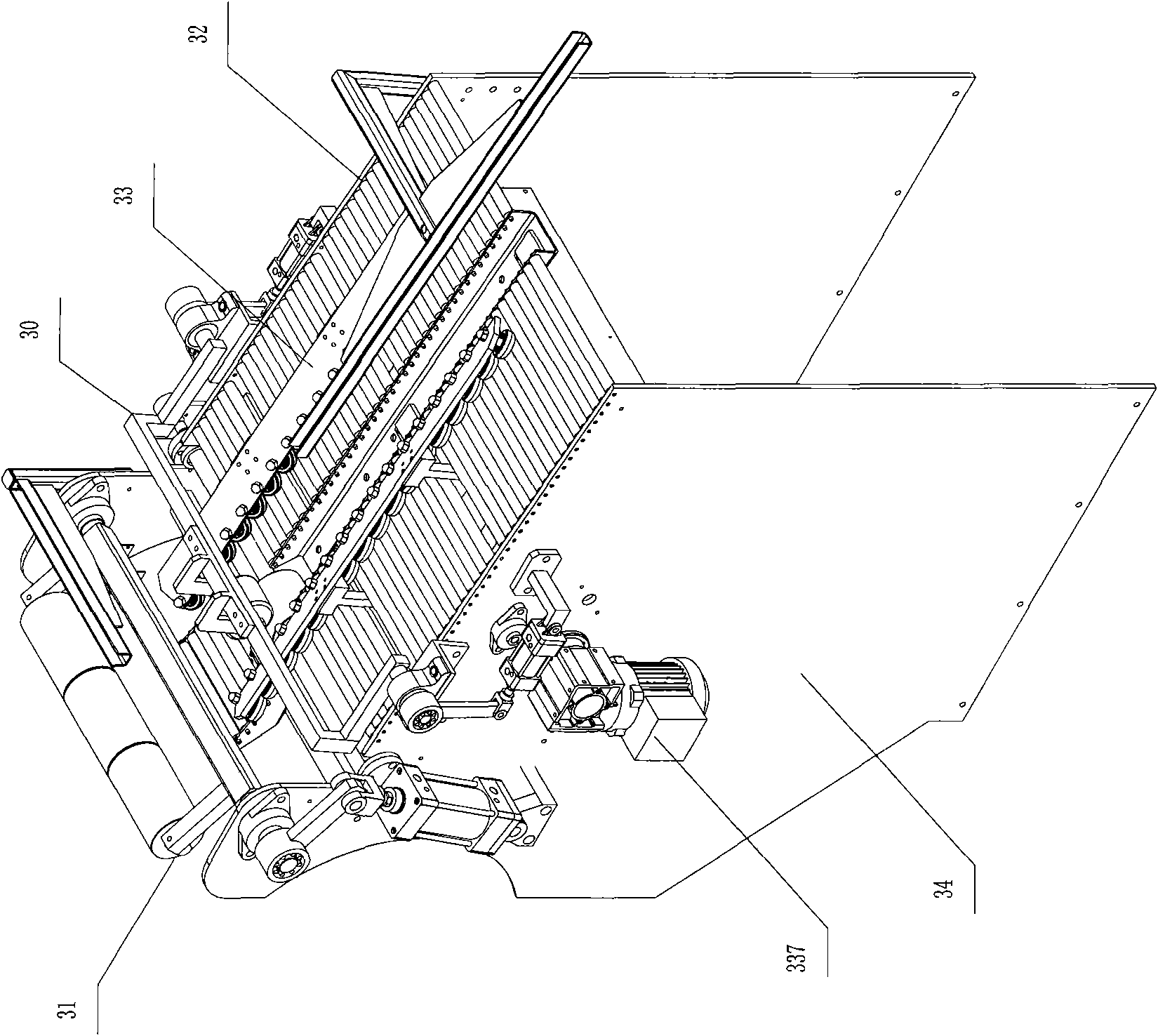

[0073] like Figure 3 to Figure 10 As shown, the front conveying device 3 has a front pressing roller assembly 30 , an intermediate pressing roller assembly 31 , a conveying roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com