Method for treating and recycling MTO process wastewater

A wastewater treatment and process technology, applied in aerobic and anaerobic process treatment, natural water treatment, biological water/sewage treatment, etc. Reusing reports, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

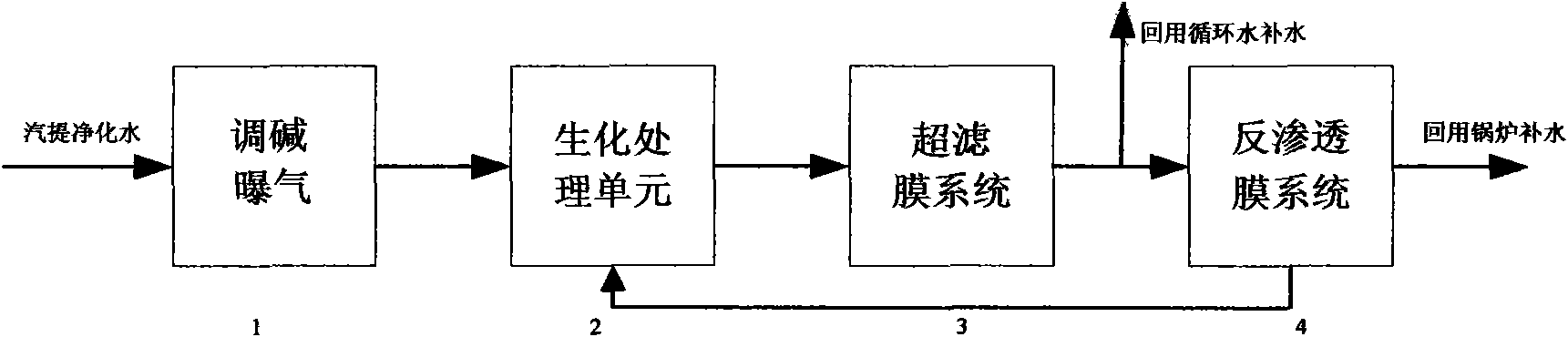

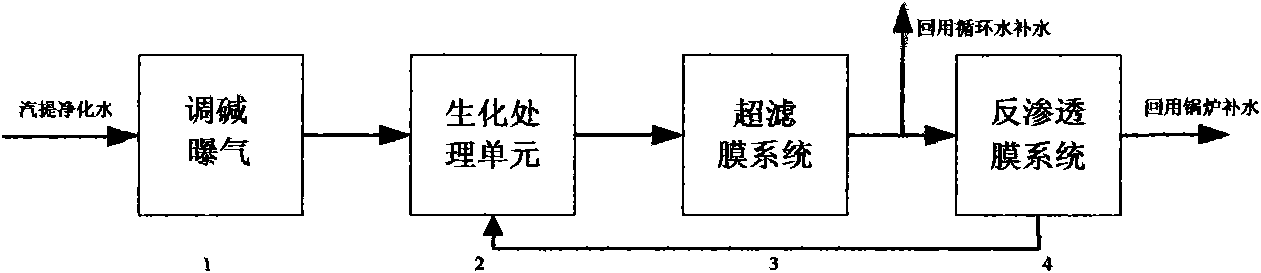

Method used

Image

Examples

Embodiment 1

[0034] The main water quality characteristics of the purified water at the bottom of the stripping tower in the MTO process: the temperature of the purified water is 3°C, the pH is 5, and the COD cr The content of methanol is 400mg / L, the content of methanol is 50mg / L, the content of acetic acid is 100mg / L, and the conductivity is 100μs / cm. The oxygen is 3mg / L, and the sludge concentration is 1.6g / L.

[0035] The waste water after aerobic biochemical treatment enters the PVDF hollow fiber ultrafiltration membrane system with a pore size of 0.05 μm after being settled by the sand filter device in the secondary sedimentation tank. 2 h, after the time interval between water inlet at both ends is 45 minutes, the dispersive washing operation of adding alkali first and then adding acid is carried out, the acid-base dosing cleaning time is 10 seconds, and then the normal operation is continued after 5 seconds of washing operation; the process After repeating the operation 10 times, ...

Embodiment 2

[0039] Water quality characteristics of the purified water at the bottom of the stripping tower of the MTO process: the temperature of the purified water is 40°C, the pH is 8, and the COD cr The content of methanol is 600mg / L, the content of methanol is 100mg / L, the content of acetic acid is 500mg / L, and the conductivity is 800μs / cm. The dissolved oxygen is 4.5mg / L, and the sludge concentration is 3.5g / L.

[0040] After aerobic biochemical treatment, it settles through the sand filter device of the secondary sedimentation tank and enters the PES hollow fiber ultrafiltration membrane system with a pore size of 0.2 μm. It operates in the way of cross-flow filtration, and the operating flux of the ultrafiltration membrane is 300L / m 2 h, after 30 minutes of water inflow at both ends, the dispersive washing operation of adding alkali and acid is carried out. The washing time of acid and alkali is 12 seconds, and then the normal operation is continued after 8 seconds of washing oper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductance | aaaaa | aaaaa |

| Conductance | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com