High-accelerated speed linear electromagnetic propelling system

A linear electromagnetic and propulsion system technology, applied in the direction of propulsion systems, electromechanical devices, electric vehicles, etc., can solve the problems of low power factor of linear induction motors, achieve the effect of increasing acceleration and payload, reducing capacity and cost, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

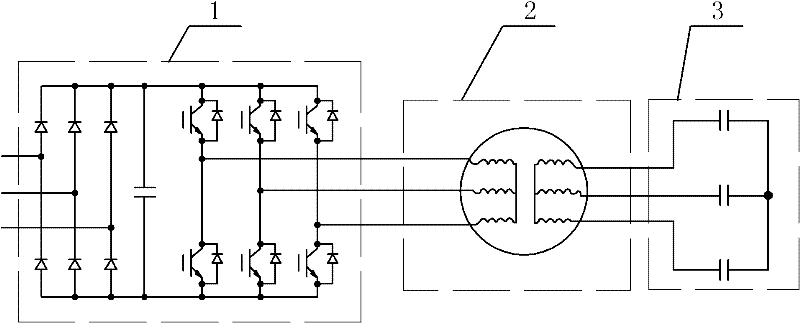

[0019] Specific implementation mode one: the following combination figure 1 , figure 2 and image 3 Describe this embodiment, this embodiment is made up of power converter 1, linear motor 2 and excitation capacitor 3,

[0020] Each capacitor in the exciting capacitor 3 is connected in a star shape or a polygon;

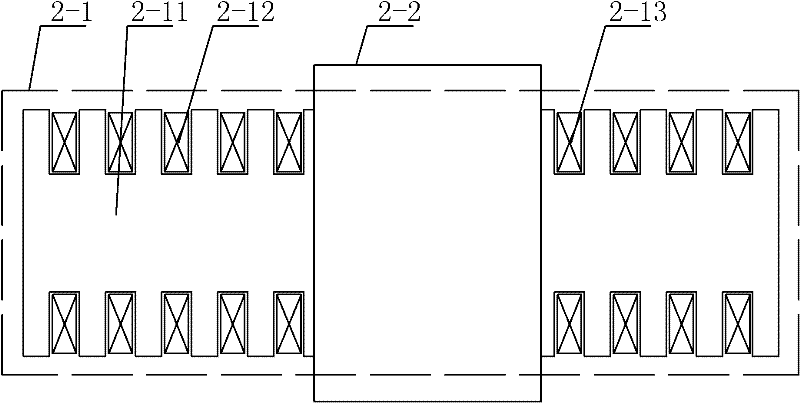

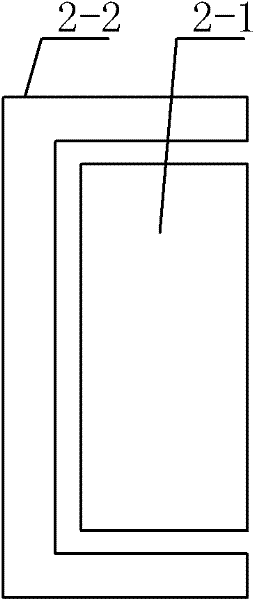

[0021] The linear motor 2 includes an armature 2-1 and a secondary 2-2, the secondary 2-2 is in the shape of a gate, the two vertical sides of the secondary 2-2 gate are conductor plates, and the inner side of the conductor plate is a low-resistivity metal material, the outer side of the conductor plate is a high magnetic permeability metal material; the secondary 2-2 straddles the armature 2-1, and the inner side of the secondary 2-2 is separated from the upper surface and both sides of the armature 2-1 by an air gap relatively;

[0022] The armature 2-1 is composed of the main iron core 2-11, the main winding 2-12 and the auxiliary winding 2-13. -13 is embedde...

specific Embodiment approach 2

[0025] Specific implementation mode two: the following combination Figure 4 and Figure 5 Describe this embodiment. The difference between this embodiment and Embodiment 1 is that it also includes two auxiliary iron cores 2-14, one auxiliary iron core 2-14 is provided on both sides of the air gap side of the armature 2-1, and the secondary The outer sides of each vertical edge of the 2-2 door shape are respectively opposite to an auxiliary iron core 2-14 separated by an air gap. Other components and connections are the same as those in Embodiment 1.

[0026] In this embodiment, the two auxiliary cores 2-14 are not slotted.

specific Embodiment approach 3

[0027] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that each of the main winding 2-12 and the auxiliary winding 2-13 is a set of annular windings or there is a set of each in the slots on each side of the main core 2-11. A main winding 2-12 and a set of auxiliary windings 2-13. Other compositions and connections are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com