Central electrode conveying and loading device

A center electrode, feeding and loading technology, which is applied in the manufacture of spark plugs, etc., can solve the problems that the center electrode cannot be loaded and affects work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

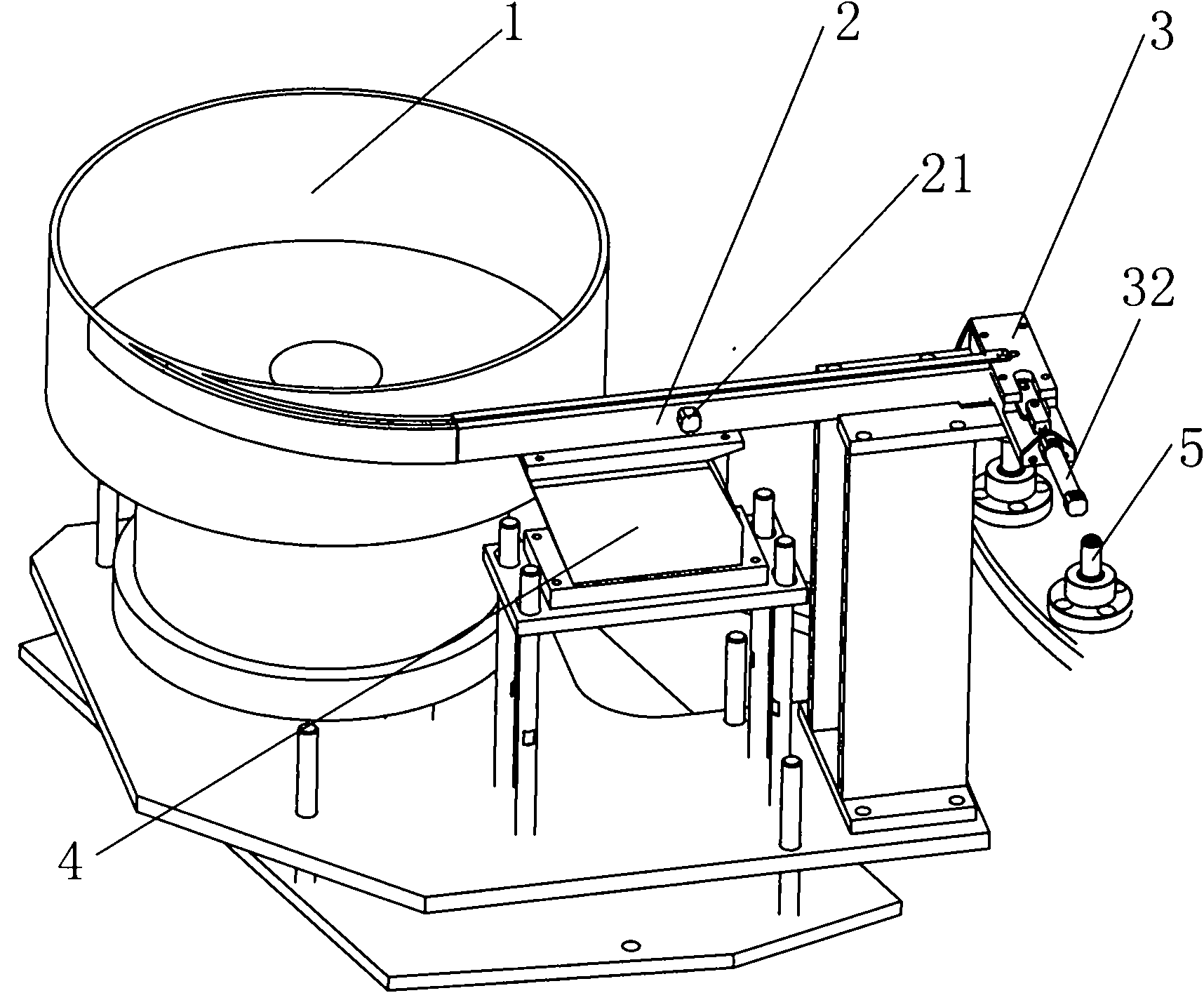

[0027] Embodiment: A central electrode feeding and feeding device, which consists of a vibrating plate 1 for storing the central electrode, a feeding track 2 for conveying the central electrode, and a feeding mechanism 3 for assembling the central electrode. The central electrode on the track 2 is transferred to the material blocking and distribution plate 31 and the cylinder 32 corresponding to the central hole of the ceramic column.

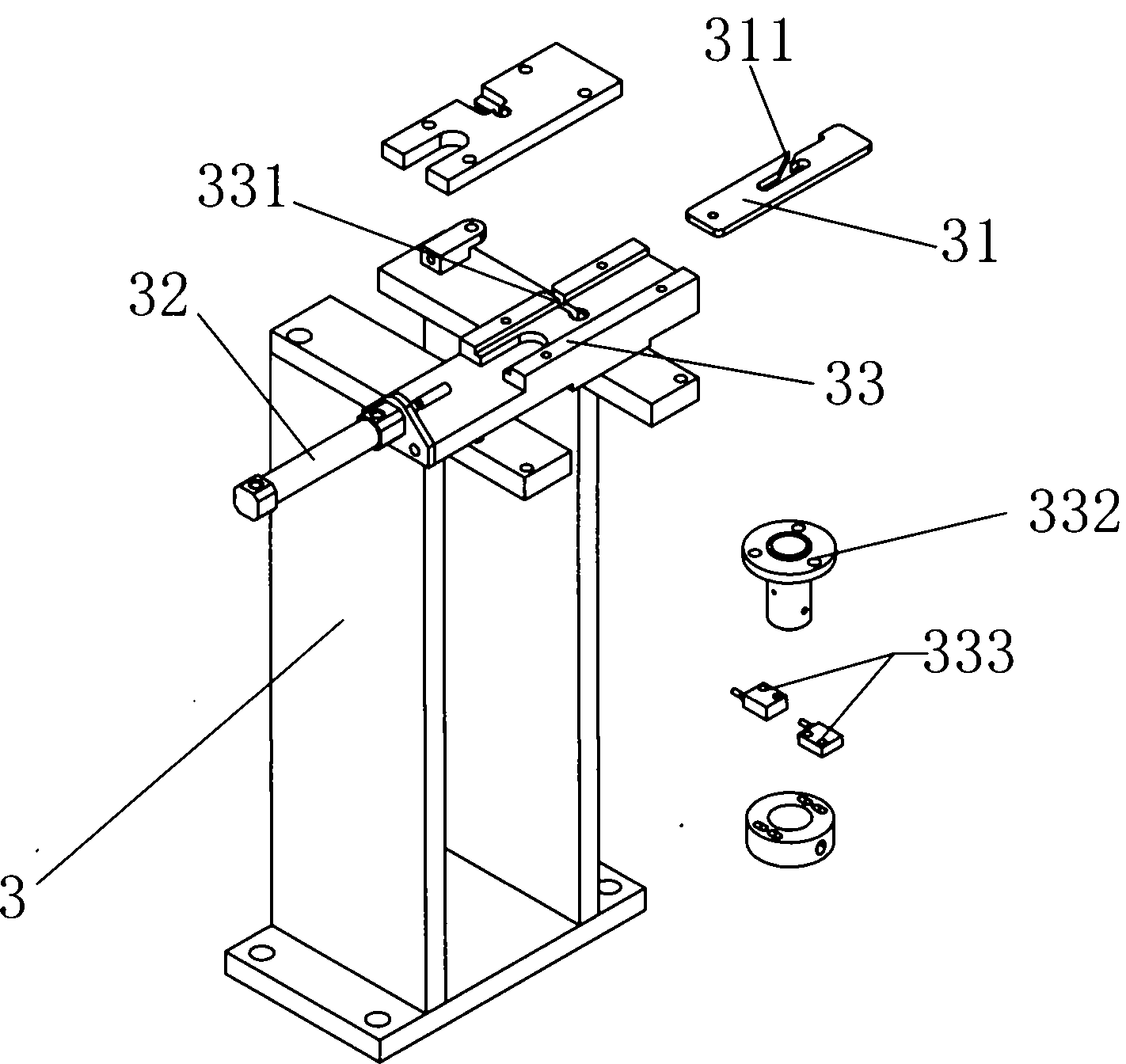

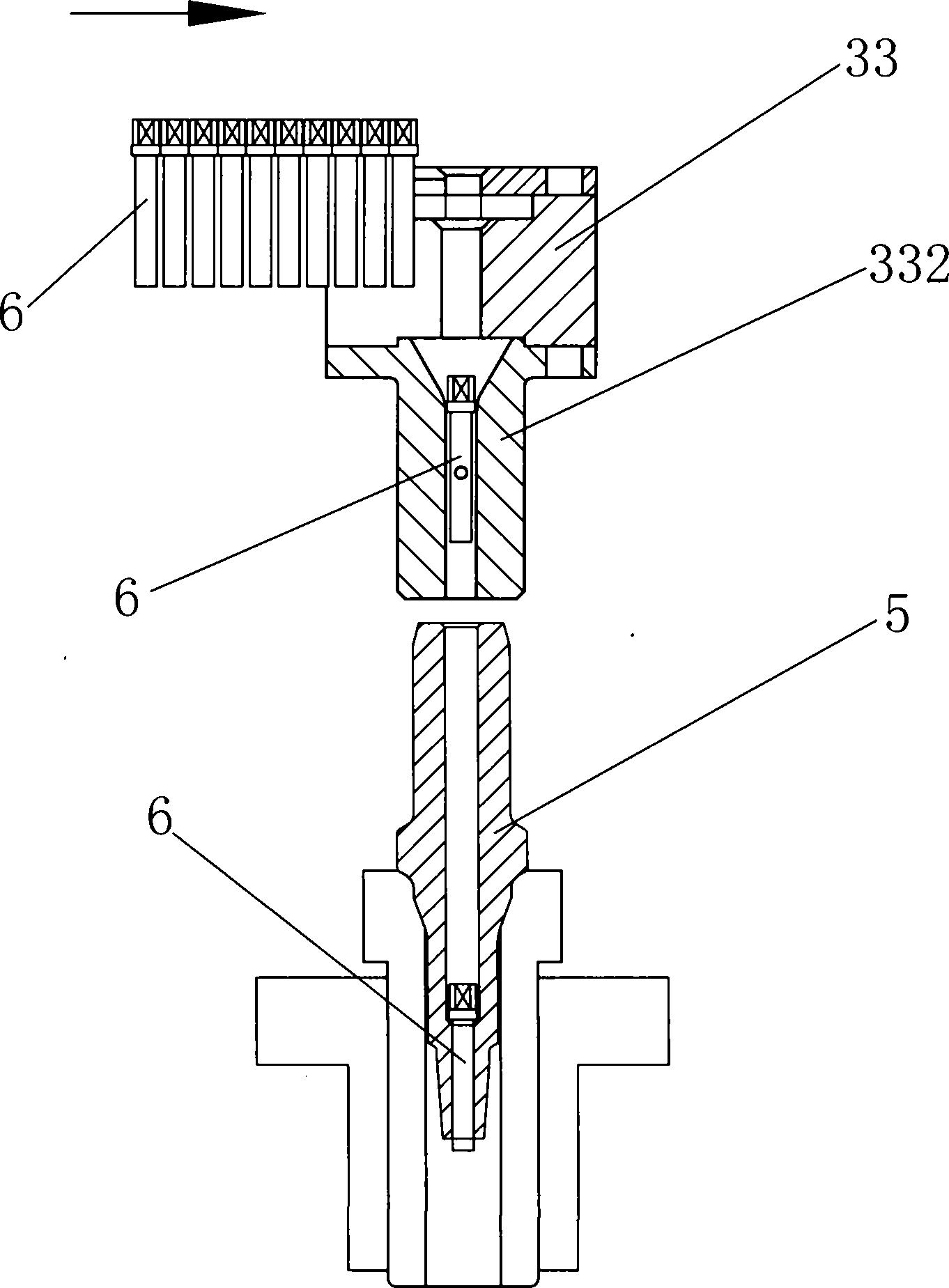

[0028] The blocking and distributing plate 31 is placed in the chute 33 on the feeding mechanism 3 and controlled to slide by the air cylinder 32. The chute 33 is provided with one end connected to the discharge port of the feeding track 2 and the other end corresponding to the porcelain column The transverse groove 331 of the central hole 5, the material blocking and distribution plate 31 is provided with an oblique groove 311 whose one end communicates with the transverse groove 331 and the other end corresponds to the central hole 5 of the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com