Making method of long and crisp pepper

A technology for crispy peppers and sea peppers, which is applied in the field of preparation of long crispy peppers, can solve problems such as product sales limitations, and achieve the effects of scientific process, rich nutrition and significant economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

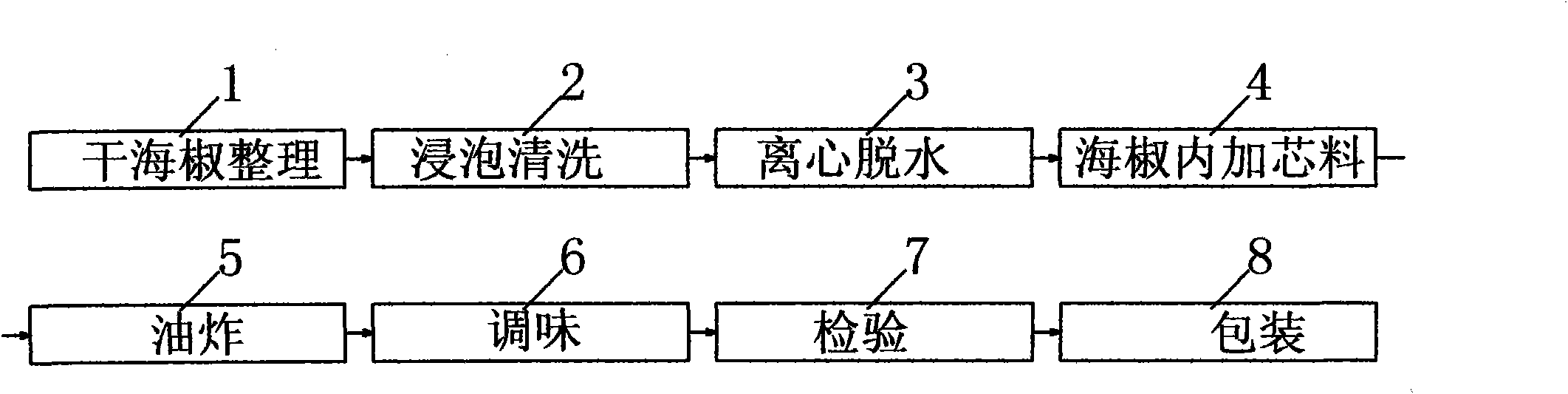

[0017] A method for preparing long-flavored and crispy peppers. The production process is as follows: dried sea peppers finishing 1—soaking and cleaning 2—centrifugal dehydration 3—sea peppers with core material 4—fried 5—seasoning 6— Inspection 7—Packaging 8; core materials are mainly walnut kernels, sesame seeds, peanut kernels, sunflower kernels, and starch. The dry sea pepper sorting 1 is to remove the two ends of the long dried sea pepper and the core and seeds of the dried sea pepper. The soaking and cleaning time of the dried sea pepper is 20-30 hours. The ratio of the core material in parts by weight is: 1-6 parts of walnut kernels, 30-50 parts of sesame seeds, 10-30 parts of peanut kernels, 5-20 parts of sunflower kernels and 20-30 parts of starch. The core material 4 in the sea pepper adopts manual filling core material. Frying 5 is to fry the sea pepper with the core material in the oil pan. Seasoning 6 is to add appropriate monosodium glutamate, salt and seasoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com