Electronic liquid filling device

A filling device and electronic technology, which is applied in the field of electronic liquid filling devices, can solve the problems of increasing, inability to effectively realize exhaust and pressure relief, unfavorable output, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The electronic liquid filling machine in the prior art includes a material cylinder for containing the liquid to be filled into the liquid container, an electronic liquid filling device for filling the liquid in the material cylinder into the liquid container, A container pushing mechanism for pushing the liquid container to / from a position where it can be filled by the electronic liquid filling device and a rotating disk for driving the electronic liquid filling device and the material cylinder to rotate relative to the container pushing mechanism. Since the present invention only relates to the improvement of the electronic liquid filling device, it only focuses on the structure and operation of the electronic liquid filling device, and omits the electronic liquid filling machine which is the same as the prior art and is similar to the present invention. Improve instructions for other parts that are not relevant.

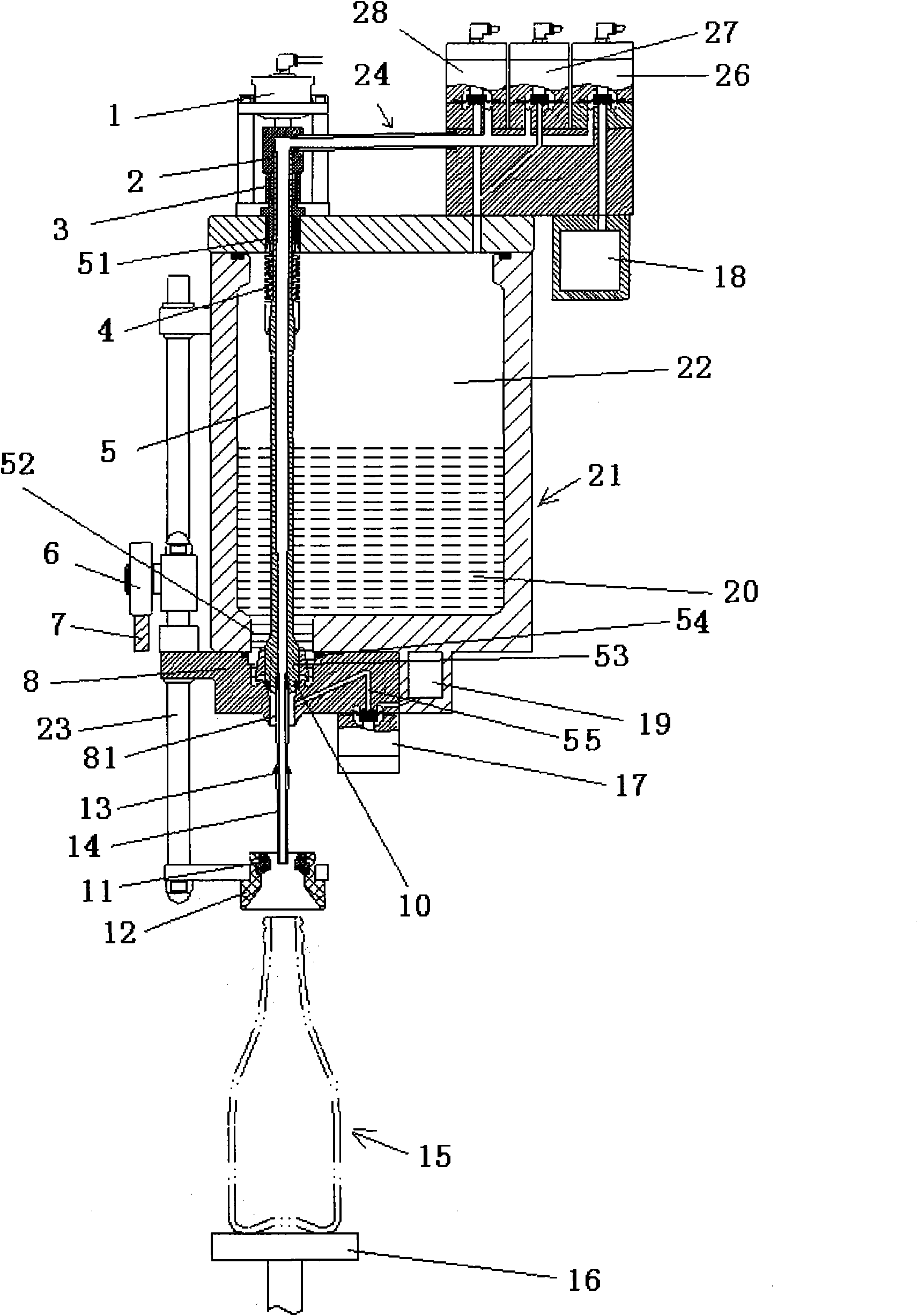

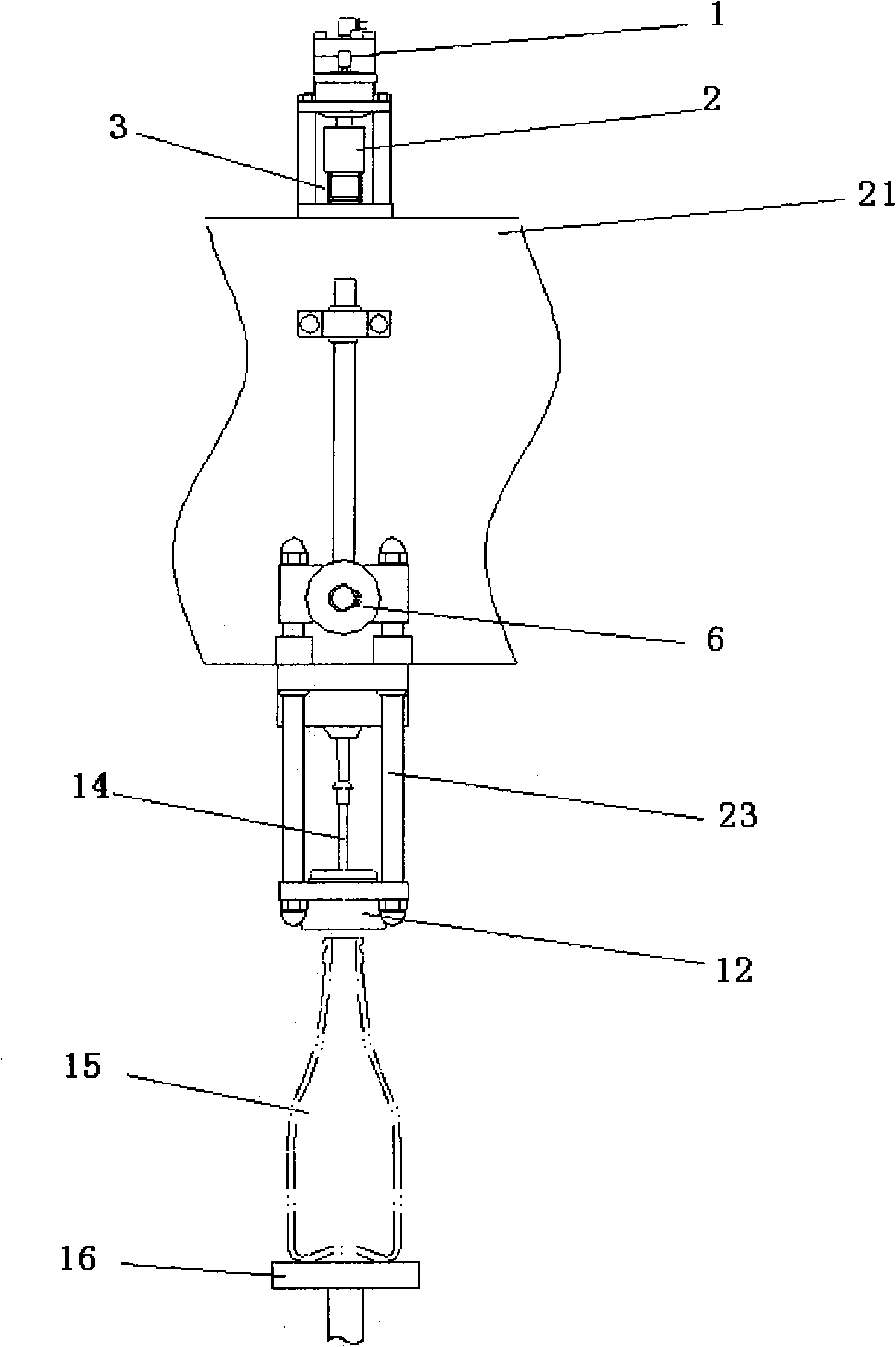

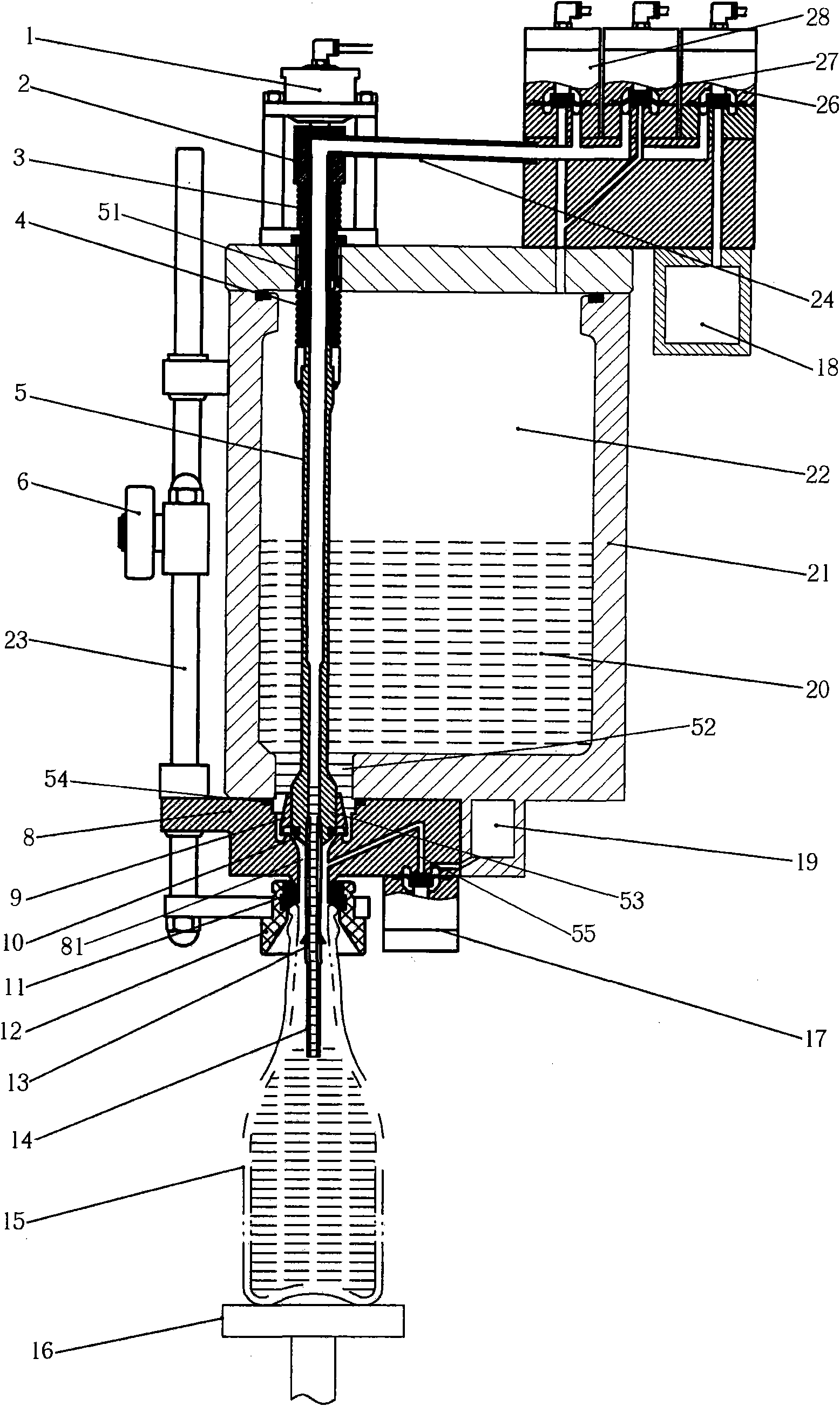

[0012] figure 1 Shown is the structure of the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com