Drinking water softener and softening method and equipment thereof

A softener and drinking water technology, applied in the direction of water softening, etc., can solve the problems of non-application and water application restrictions, and achieve the effects of eliminating scaling tendency, low investment and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Sodium carbonate, calcium carbonate, clay and water are mixed in a weight ratio of 10:20:70:100, stirred evenly, and poured into a mold. Put the mold into an oven and dry it at 100°C to obtain sodium carbonate sustained-release granules. The granules are embedded in a polyvinylidene fluoride microporous membrane with a pore size of 1 micron, and then the polyvinylidene fluoride microporous membrane embedded with sodium carbonate sustained-release particles is filled into a cylindrical plastic shell to form a Slow release softening filter.

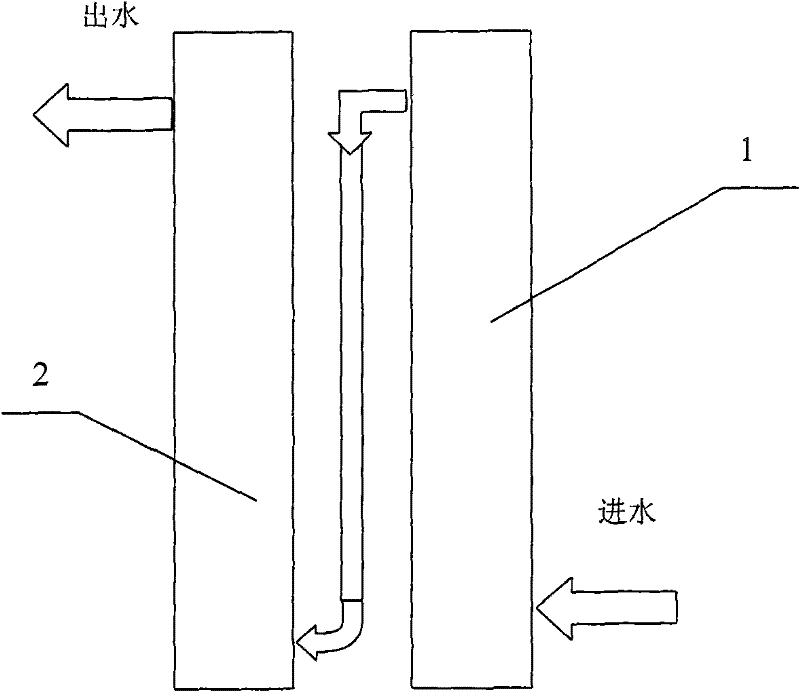

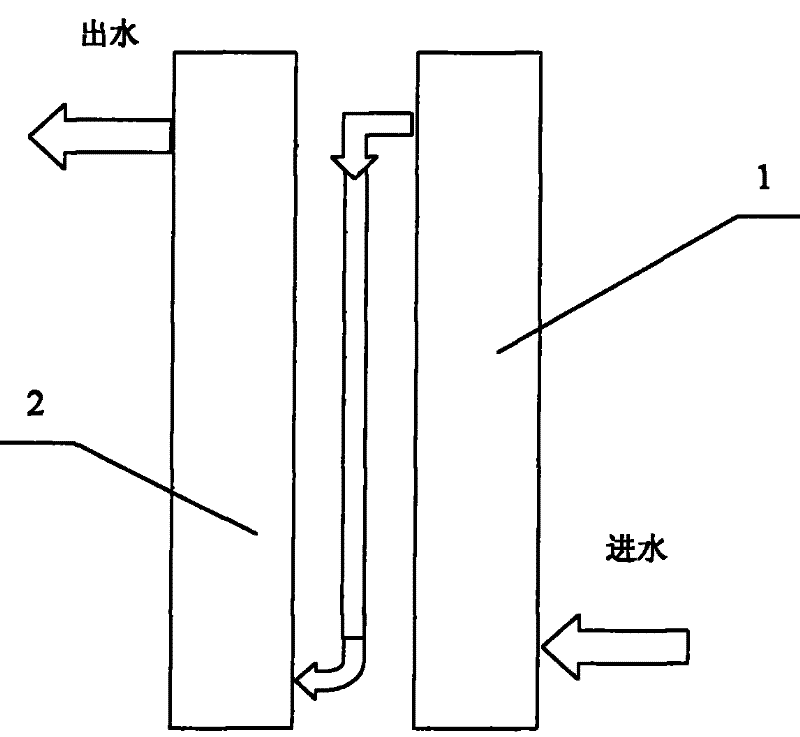

[0032] Calcium hardness is 300ppm (as CaCO 3 meter), pH = 7 water through such as figure 1 device shown. figure 1 Among them, a device for partially softening drinking water, including a slow-release softening filter element 1 and an ultrafiltration device 2.

[0033] Then detect the pH value of water, turbidity and calcium hardness, obtain: pH=7.6, turbidity3 count).

Embodiment 2

[0035] Sodium carbonate, calcium carbonate, clay and water are mixed in a weight ratio of 20:20:60:100, stirred evenly, and poured into a mold. Put the mold into an oven and dry it at 100°C to obtain sodium carbonate sustained-release granules. The granules are embedded in a polyvinylidene fluoride microporous membrane with a pore size of 2 to 3 microns, and then the polyvinylidene fluoride microporous membrane embedded with sodium carbonate sustained-release particles is filled into a cylindrical plastic shell, Made into a slow-release softening filter.

[0036] Calcium hardness is 400ppm (as CaCO 3 meter), pH = 7 water through such as figure 1 device shown. figure 1 Among them, a device for partially softening drinking water, including a slow-release softening filter element 1 and an ultrafiltration device 2.

[0037] Then detect the pH value of water, turbidity and calcium hardness, obtain: pH=8.2, turbidity3 count).

[0038] The results show that the calcium hardness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com