Device and method for controlling discharge of sintering bunker group

A control device and control method technology, applied in chemical instruments and methods, dissolution, furnace types, etc., can solve problems such as waste of manpower, waste of silo resources, troubles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

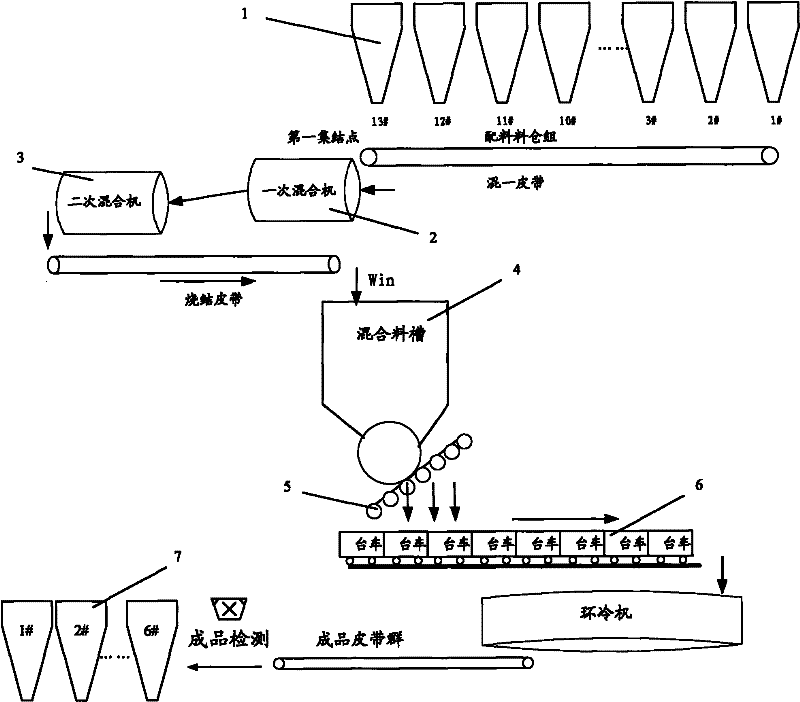

[0060] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0061] The technical problem to be solved by the present invention is to provide a control device and method for unloading of sintering bunker groups, which can realize the coordinated unloading problem among the corresponding bunkers of each raw material in the unloading group of the sintering system.

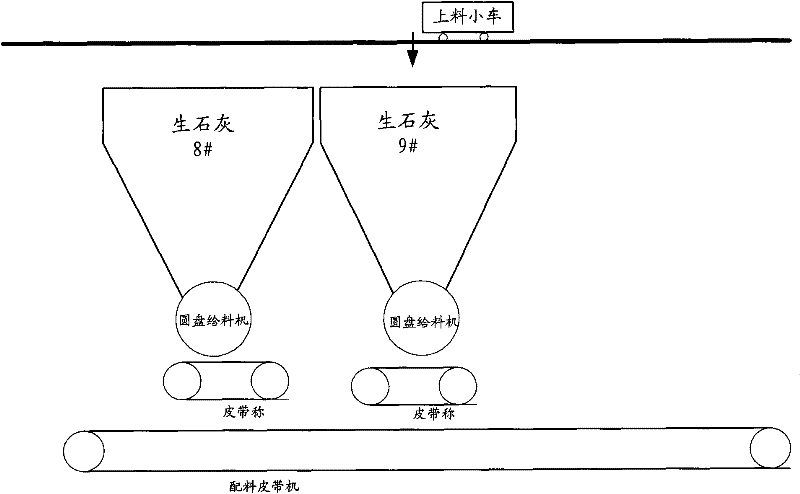

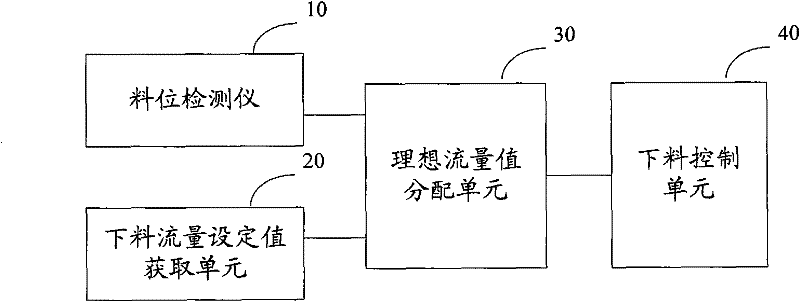

[0062] The principle of the control device for unloading of sintering bunker group according to the present invention is: for a plurality of bunkers corresponding to the same raw material, according to the current material level value of each bunker, the ideal feeding flow rate value is allocated to each bunker in proportion . For a silo with a higher current material level and a large stock, the ideal discharge flow value is assi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com