Electrical drive machine having stator and rotor

A technology for driving motors and rotors, applied to electrical components, electromechanical devices, DC commutators, etc., can solve problems such as reducing service life and achieve the effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

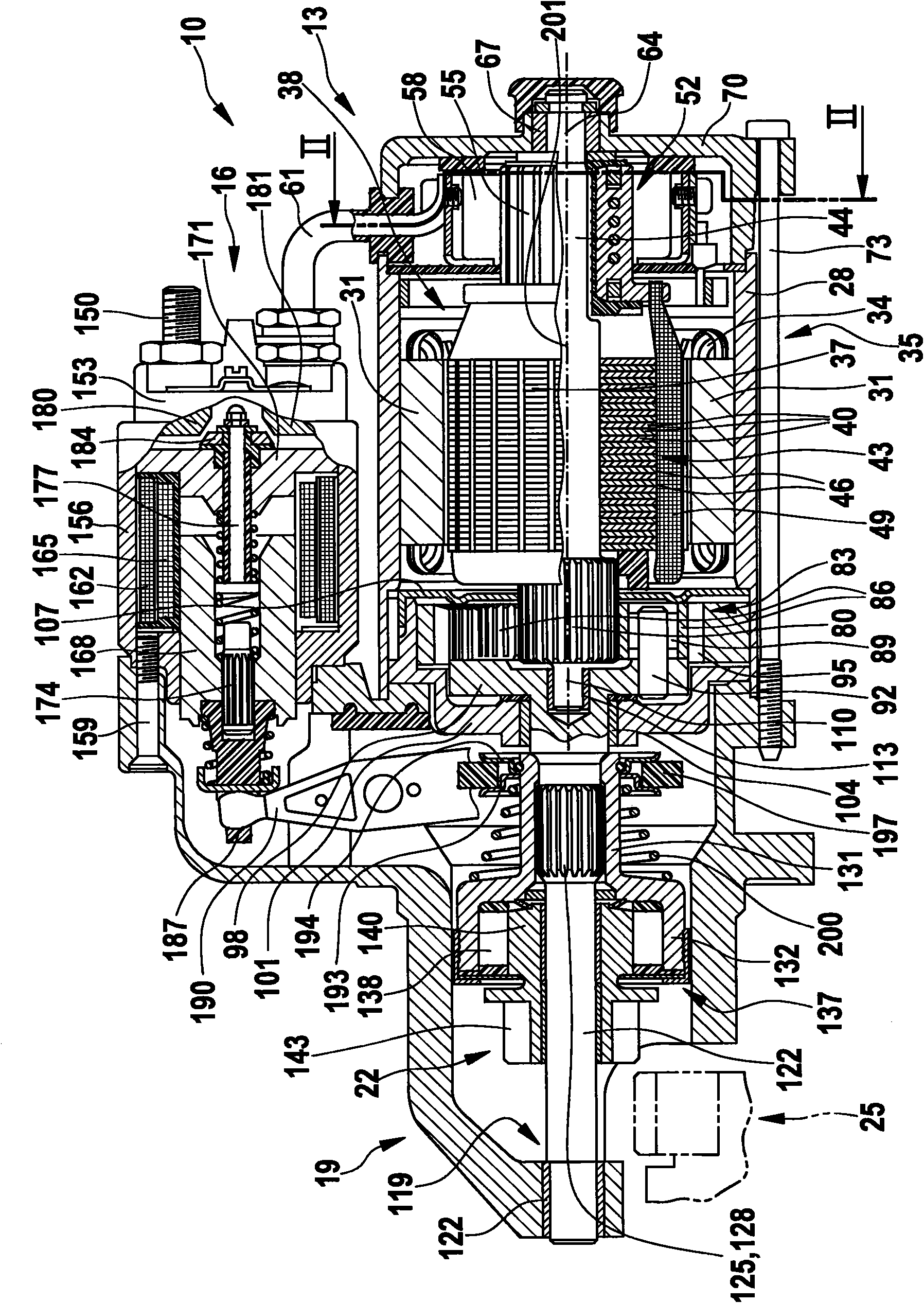

[0010] figure 1 The starting device is shown in longitudinal section. exist figure 1 The starting device 10 is shown in . The starter device 10 has, for example, a starter motor 13 and a switching relay 16 . Both starter motor 13 and switching relay 16 are fastened in a common drive end bearing housing 19 . The starter motor 13 is functionally available to drive the starter pinion 22 when the starter pinion 22 meshes in a ring gear 25 of the internal combustion engine (not shown here).

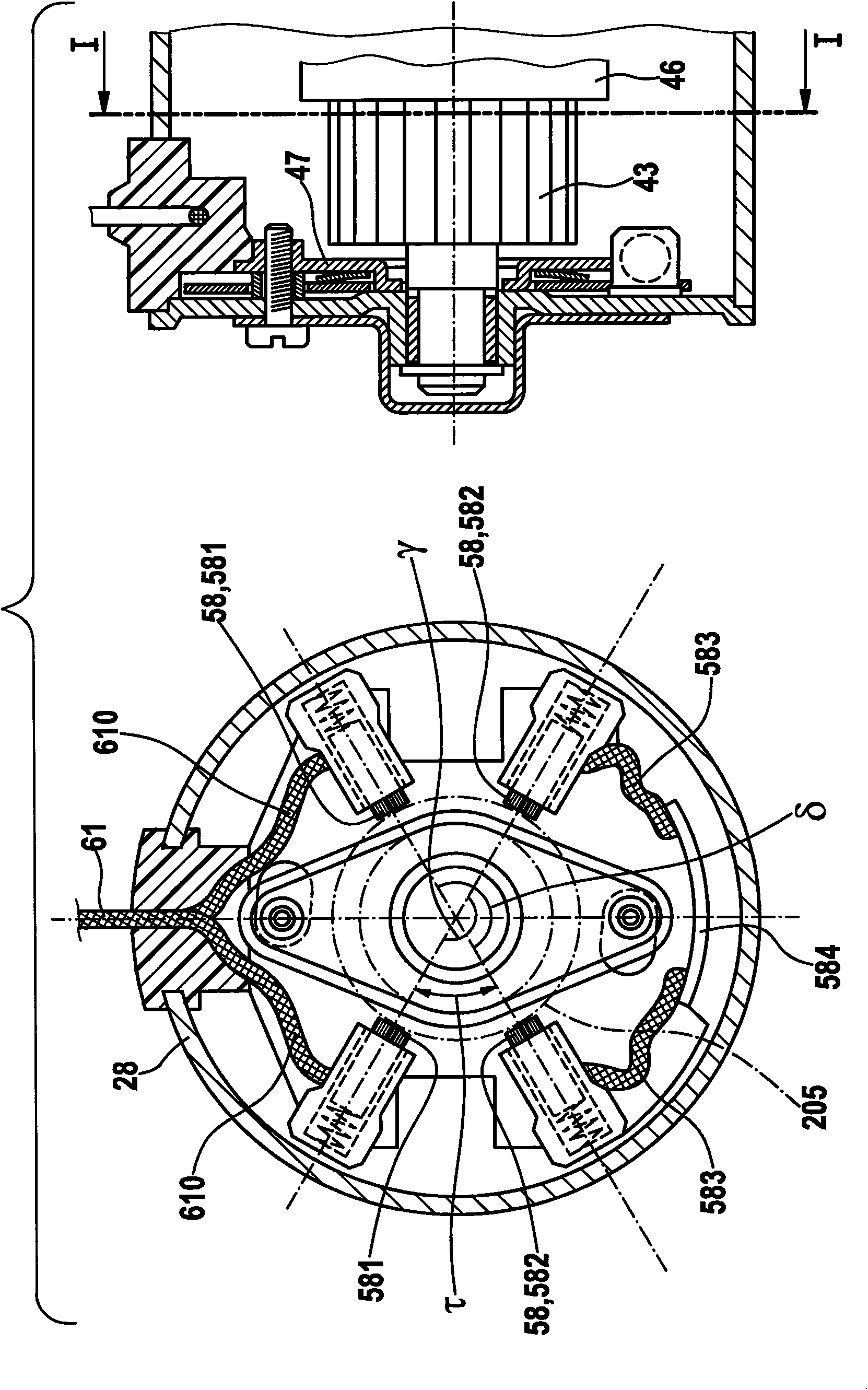

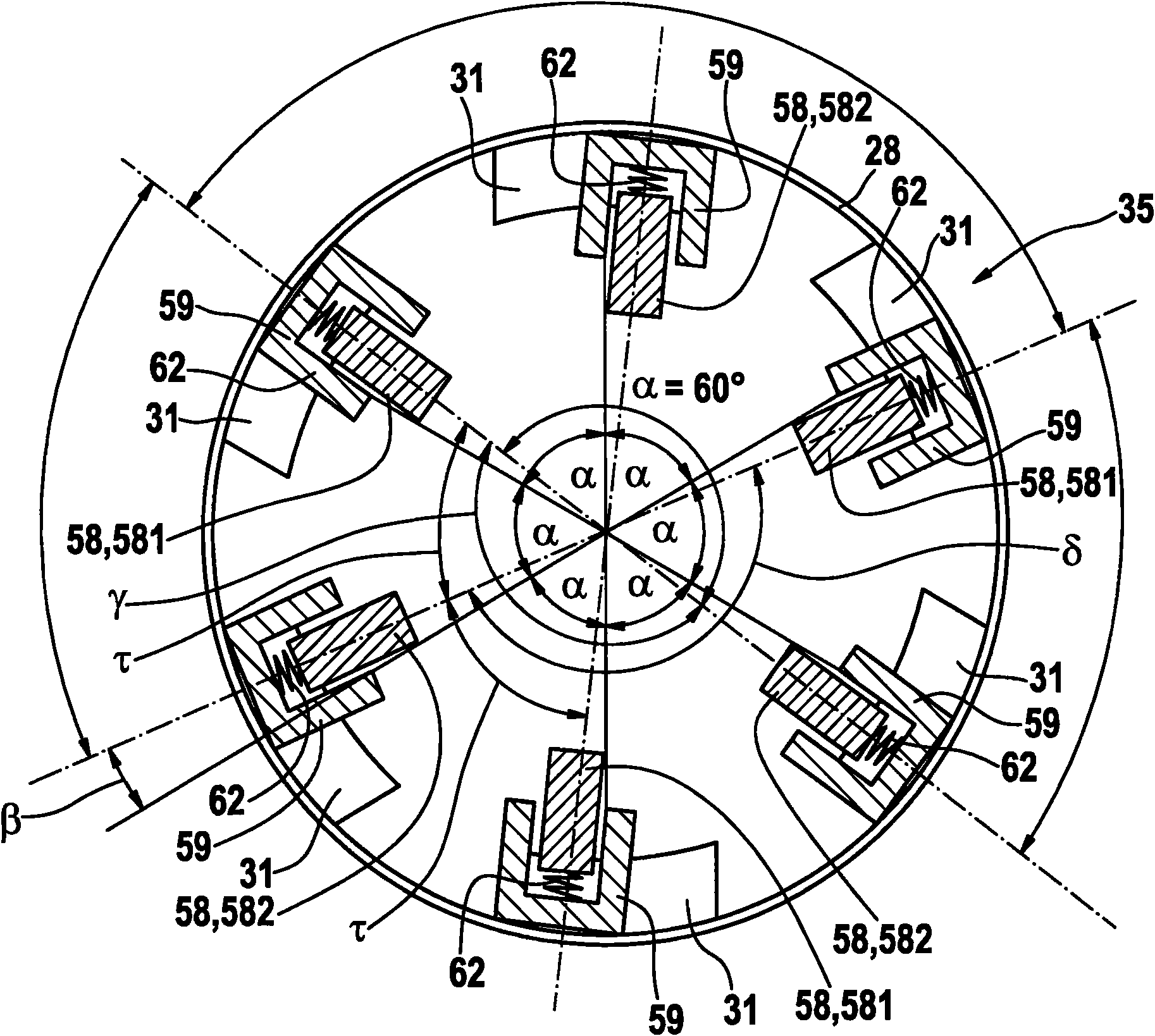

[0011] The starter motor 13 as a drive motor of the starter has a pole tube 28 as a housing, which has a plurality of pole shoes 31 each wound by a field winding 34 on its inner periphery. The pole shoe 31 in turn surrounds an armature 37 , ie a rotor 38 , which has an armature core 43 consisting of laminations 40 and an armature or rotor winding 49 arranged in slots 46 . The armature core 43 is pressed against the drive shaft 44 . Also mounted on the end of the drive shaft 44 remote fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com