Composite calcium-based lubricating grease and preparation method thereof

A complex calcium-based, grease technology, used in lubricating compositions, petroleum industry, additives, etc., can solve problems such as surface hardening, and achieve the effect of improving surface hardening performance, improving arrangement and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

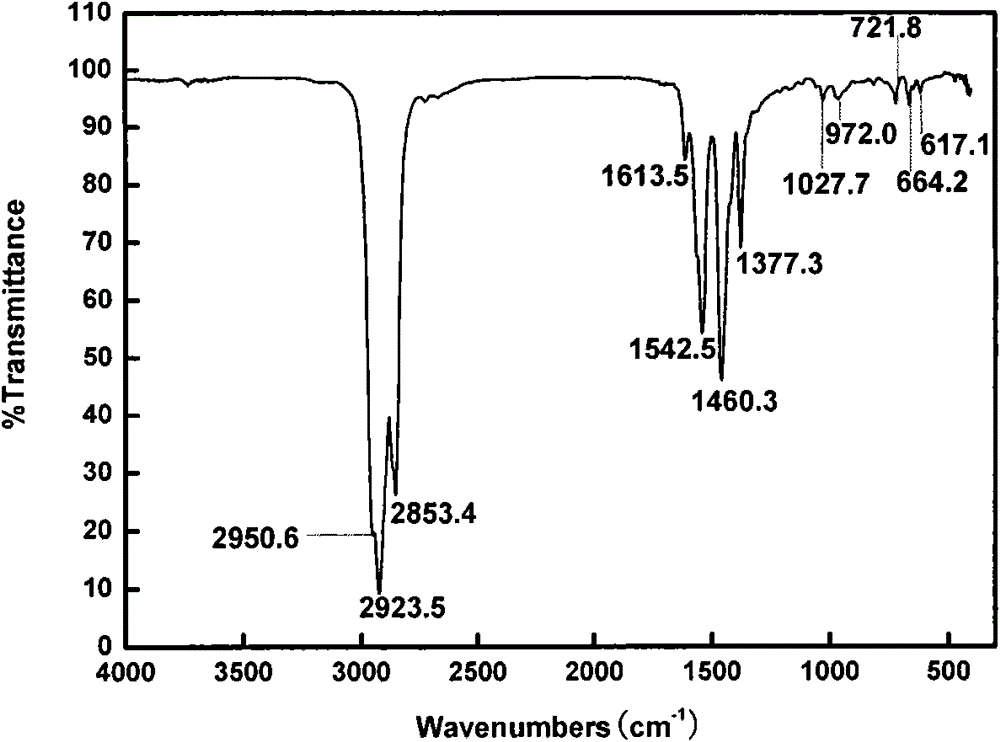

Image

Examples

Embodiment 1

[0030] Embodiment 1, the preparation of the complex calcium-based lubricating grease that is made up of minus second-line base oil, complex calcium-based thickener and surfactant

[0031] Using naphthenic base oil (at 100°C, the kinematic viscosity is 19.98mm 2 / s) as a grease base oil. Get 23.4g of stearic acid, 85g of naphthenic base oil, lime emulsion containing 3.3g of calcium hydroxide and 2g of cetyltrimethylammonium bromide into the reactor, stir and gradually heat up to 105 Saponification at constant temperature for 4 hours. Get 12g of glacial acetic acid and 7.4g of calcium hydroxide to prepare 10% calcium acetate solution, let stand and filter. After the saponification is completed, the temperature is raised, and the prepared calcium acetate solution is slowly added at 130°C for compounding. After feeding, continue to raise the temperature, and slowly add 90g of naphthenic base oil to dilute at 170°C. After the dehydration is complete, continue to heat up to 220°C...

Embodiment 2

[0032] Embodiment 2, the preparation of the complex calcium-based lubricating grease that is made up of reducing second-line base oil, complex calcium-based thickener and surfactant

[0033] Using naphthenic base oil (at 100°C, the kinematic viscosity is 8.01mm 2 / s) as a grease base oil. Get 23.4g stearic acid, 85g cycloalkyl minus second-line base oil, lime emulsion containing 3.3g calcium hydroxide and 1g didecyl dimethyl ammonium chloride, drop in the reactor, stir and gradually heat up, rise to Saponification at constant temperature at 101°C for 4 hours. Get 12g of glacial acetic acid and 7.4g of calcium hydroxide to prepare 10% calcium acetate solution, let stand and filter. After the saponification is completed, the temperature is raised, and the prepared calcium acetate solution is slowly added at 115°C for compounding. After feeding, continue to raise the temperature, and slowly add 90g of naphthenic base oil to dilute at 162°C. After dehydration is complete, conti...

Embodiment 3

[0034]Embodiment 3, the preparation of the complex calcium-based lubricating grease that is made up of reducing second-line base oil, complex calcium-based thickener and surfactant

[0035] Using naphthenic base oil minus the second line (at 100 ℃, the kinematic viscosity is 25.46mm 2 / s) as a grease base oil. Get 23.4g of stearic acid, 85g of naphthenic base oil, lime emulsion containing 3.3g of calcium hydroxide and 2g of cetyltrimethylammonium bromide into the reactor, stir and gradually heat up to 102 Saponification at constant temperature for 4 hours. Get 12g of glacial acetic acid and 7.4g of calcium hydroxide to prepare 10% calcium acetate solution, let stand and filter. After the saponification is completed, the temperature is raised, and the prepared calcium acetate solution is slowly added at 120°C for compounding. After feeding, continue to raise the temperature, and slowly add 90g of naphthenic base oil to dilute at 164°C. After the dehydration is complete, cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com