Method for undock ballasting in ship building

A technology for ships and large docks, which is applied to berths, ships, transportation and packaging, etc., and can solve problems such as ineffective use of resources and waste of space in large docks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

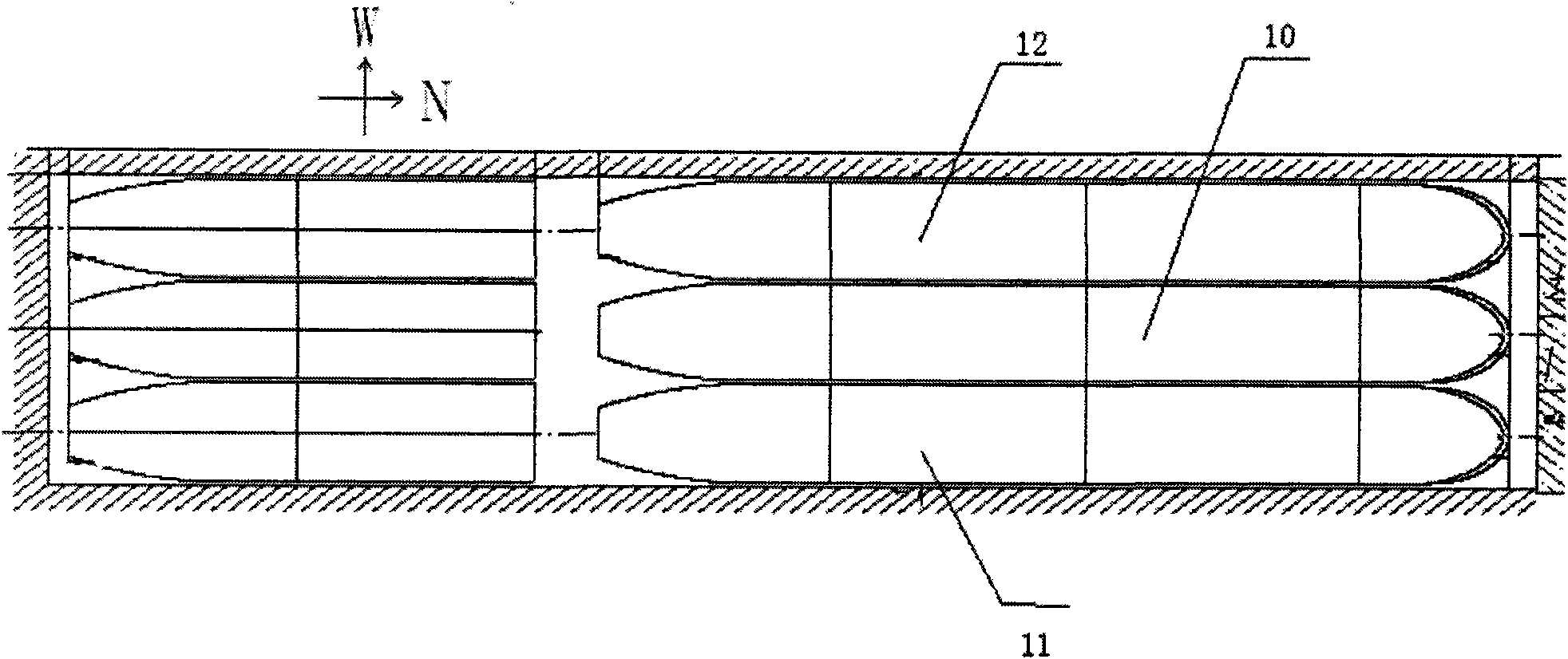

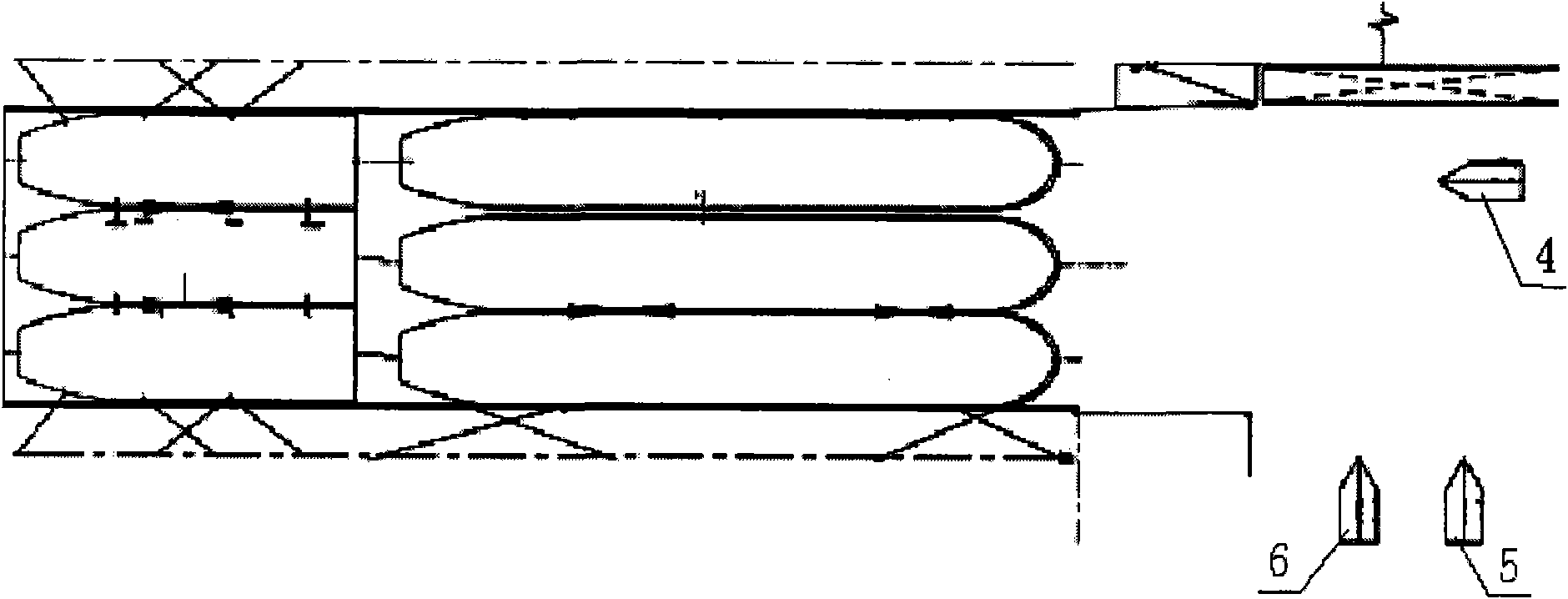

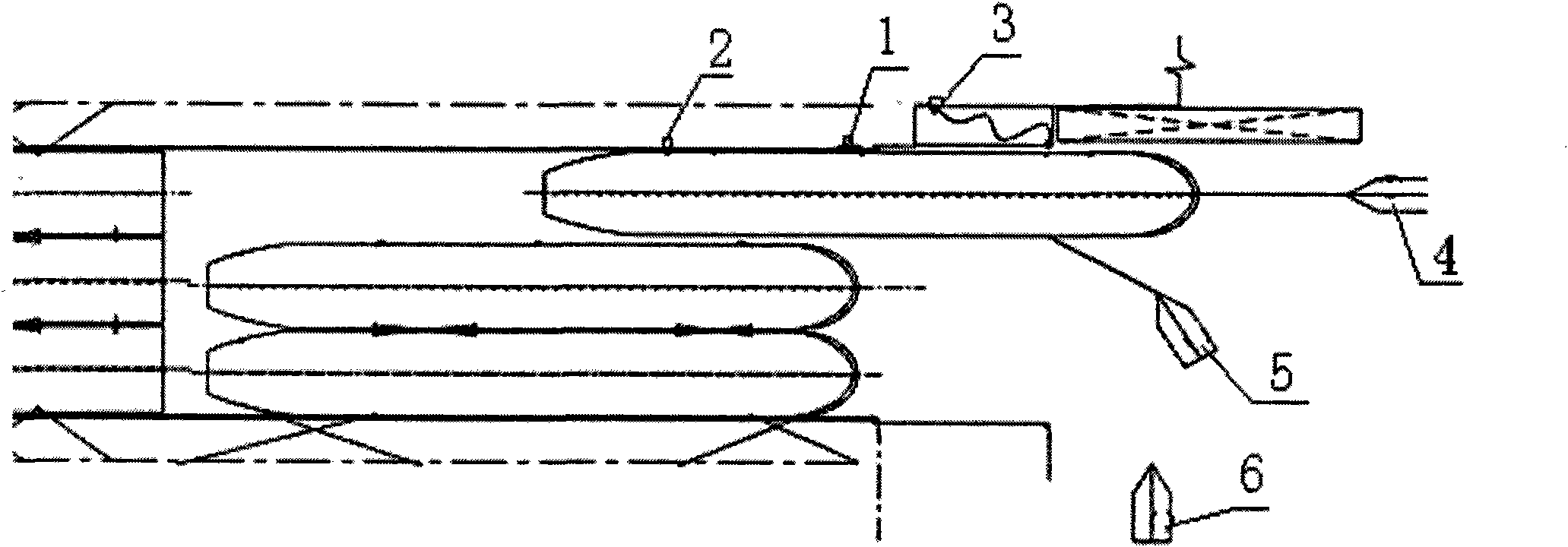

[0096] A kind of ship building method of present embodiment, technical route

[0097] 1. Equipped with technical route

[0098] When the distance between ships is 1.2 meters, determine the precision control during the loading process and how to effectively expand the construction surface.

[0099] 1.1 Improve the production quality of sections, increase the magnitude of control, and implement no-surplus production and no-surplus loading for planar sections with small hull spacing.

[0100] 1.2 Improve the precision control during hoisting, especially for the special and difficult sections of some hoisting parts, research and formulate the hoisting plan, and implement it accurately.

[0101] 1.3 Use methods such as hanging blue construction to solve the problem of unfavorable expansion of the working face when the spacing is small.

[0102] 2. Coating technology route

[0103] In the "3+3 ship building method", ship painting is required to be applied at small intervals.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com