Down-hole pumping ring and down-hole pumping device

A pumping ring and pumping technology, which is used in wellbore/well components, production fluids, earth-moving drilling, etc., can solve the problem of increasing the time for staged fracturing of oil and gas wells, low pumping efficiency, and affecting pumping bridge plugs. Speed and other issues to achieve the effect of improving pumping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

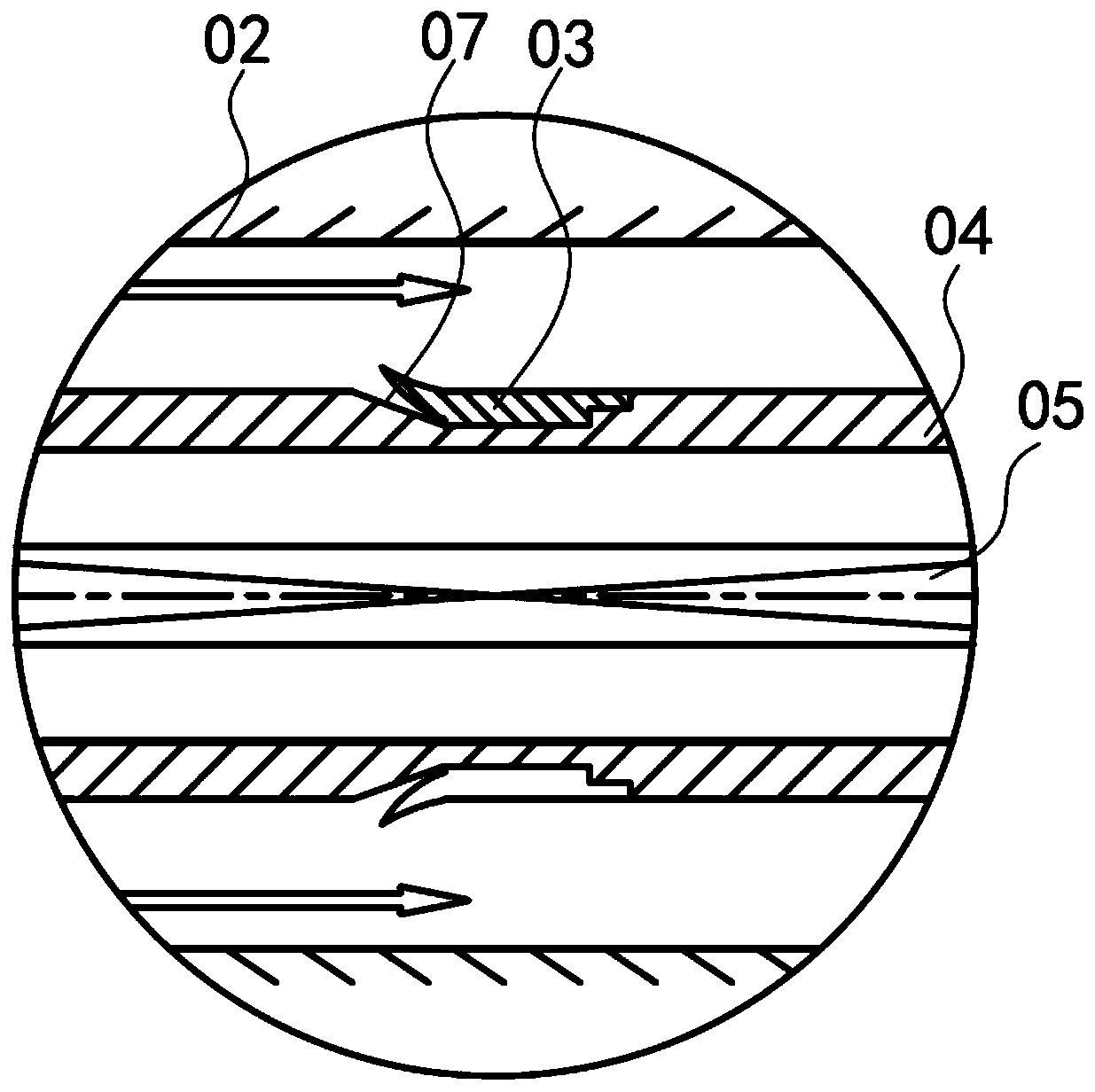

[0036] Embodiment 1 of the present invention shows a cross-sectional view of the downhole pumping ring arranged on the main body of the pumping part, see figure 1 with figure 2 ,

[0037] The pumping part main body 04 is connected with the bridge plug 06, wherein the pumping part main body 04 is a hollow cylinder, one end of the hollow cylinder 04 is used to connect with the bridge plug 06, and one end of the hollow cylinder 04 is used for For connecting with the cable tool 01, the interior of the hollow cylinder 04 is used for the passage of the sealing adapter 05. The pumping ring 03 is a ring-shaped main body with a ring structure as a whole. The inner surface of one end of the ring-shaped main body is in the shape of a truncated cone. The ring-shaped 03 main body is sleeved on the outer surface of the main body of the pumping part 04 and is flush with the outer surface The inner surface of one end of the annular 03 body and the outer surface of the pumping element body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com