Brush unit for an electric machine, spring and seal arrangement for the same, and method for the production thereof

A technology of brush sets and brushes, which is applied in the direction of electromechanical devices, electric components, circuits, etc., and can solve problems such as high material costs, increased material costs, and increased loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

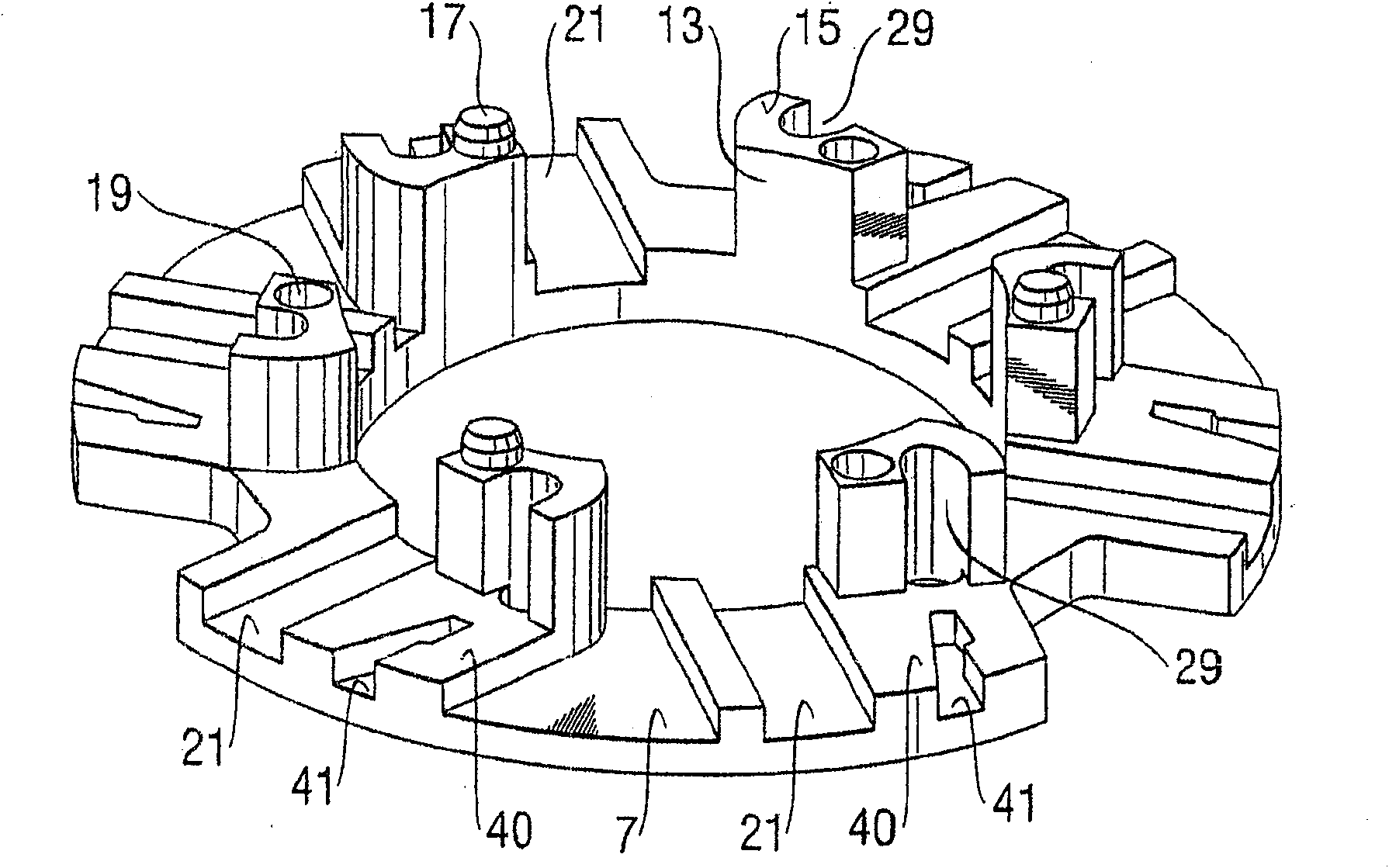

[0011] The supporting structure of the brush group is according to figure 1 It consists of 4 annular plate parts, namely an upper conductive plate 1 and a lower conductive plate 3 and an upper guide plate 5 and a lower guide plate 7 arranged therebetween. Wherein, the upper and lower conductive plates are made of metal plates with appropriate conductivity, while the upper and lower guide plates are made of electrically insulating materials, preferably injection molded parts. In the embodiment described here, the brush set has six brushes 9 , three of which are each electrically connected to the upper and lower conductor plates. The electrical connection is made via a cable 11 which is fastened, preferably by pressing, to the corresponding brush 9 and whose other end 11a is welded to the corresponding conductive plate 1 , 3 .

[0012] The guide plates 5, 7 are made into a plane on one side facing the conductive plates 1, 3, while the opposite two sides respectively have the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com