Fuse attachment structure for vacuum switch

A vacuum switch and installation structure technology, applied in the configuration/arrangement of fuses, switch devices, switch device settings, etc., can solve the problems of unstable contact points, abnormal heating, contact part offset, etc., to achieve high reliability, The error of contact resistance is small, and the effect of stable energized contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

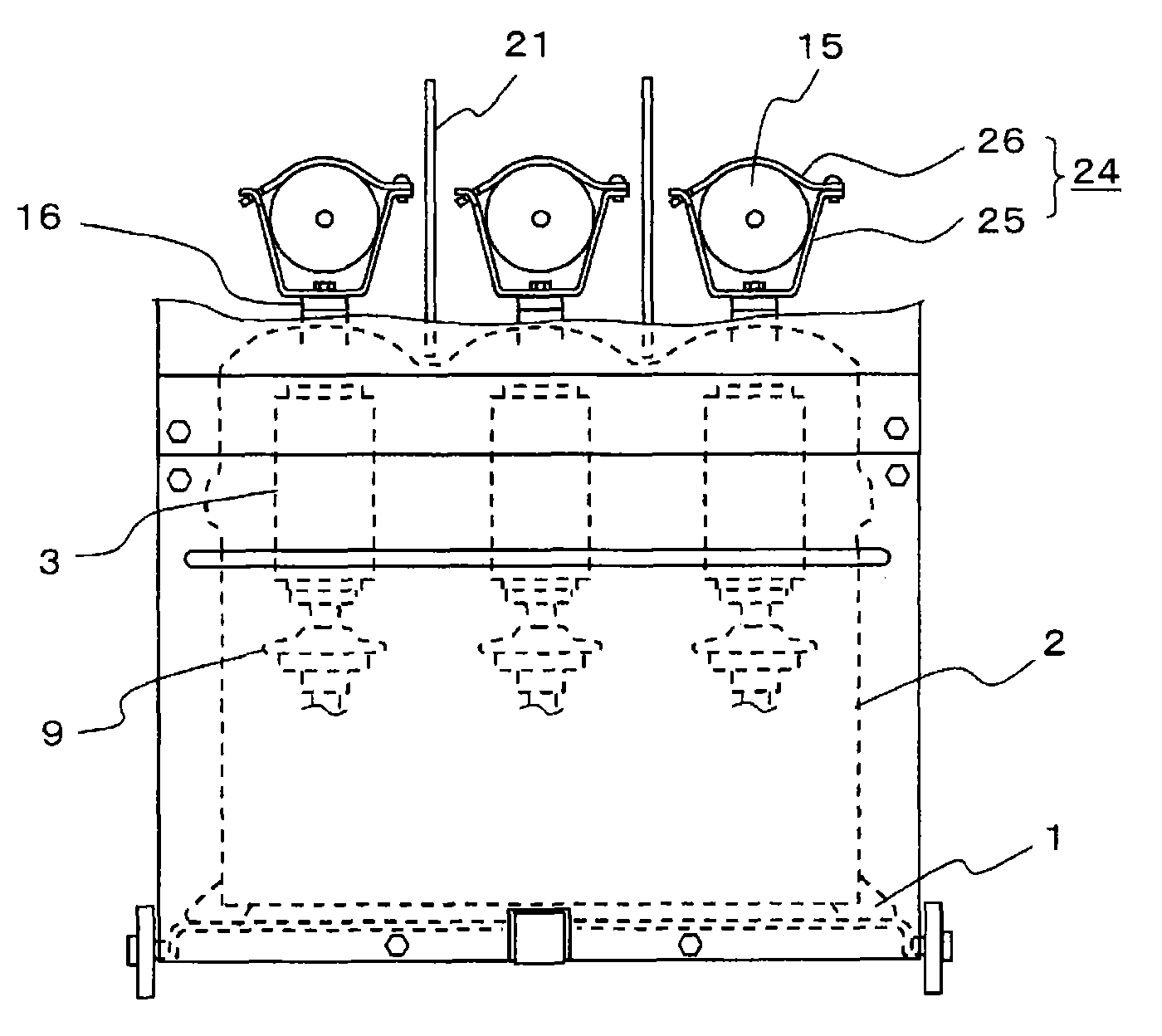

[0051] Hereinafter, the fuse mounting structure of the vacuum switch according to Embodiment 1 of the present invention will be described with reference to the drawings. figure 1 It is a front view of the vacuum switch adopting the fuse mounting structure of Embodiment 1, and shows a state in which a part of the panel on the front side is cut away to see the inside. figure 2 yes figure 1 side view.

[0052] Such as figure 1 and figure 2 As shown, in the insulating frame 2 mounted on the trolley 1, the vacuum interrupters 3 constituting the main circuit contacts of the vacuum switch are arranged in parallel in three phases. The vacuum container of the vacuum interrupter 3 contains a fixed contact 4 and a movable contact 5, the fixed rod 6 is led out from the fixed contact 4, and the movable rod 7 is led out from the movable contact 5 to the outside. The front end side of the fixed rod 6 is connected to the fixed side terminal 8 fixed on the insulating frame 2 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com