Laser pitchometer for ball-screw and measuring method thereof

A ball screw and measuring instrument technology, applied in the field of measurement, can solve problems such as the inability to guarantee the quality of high-precision ball screws and the inability to detect the accuracy of processed products, so as to improve stability and reliability, reduce measurement errors, and avoid The effect of measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

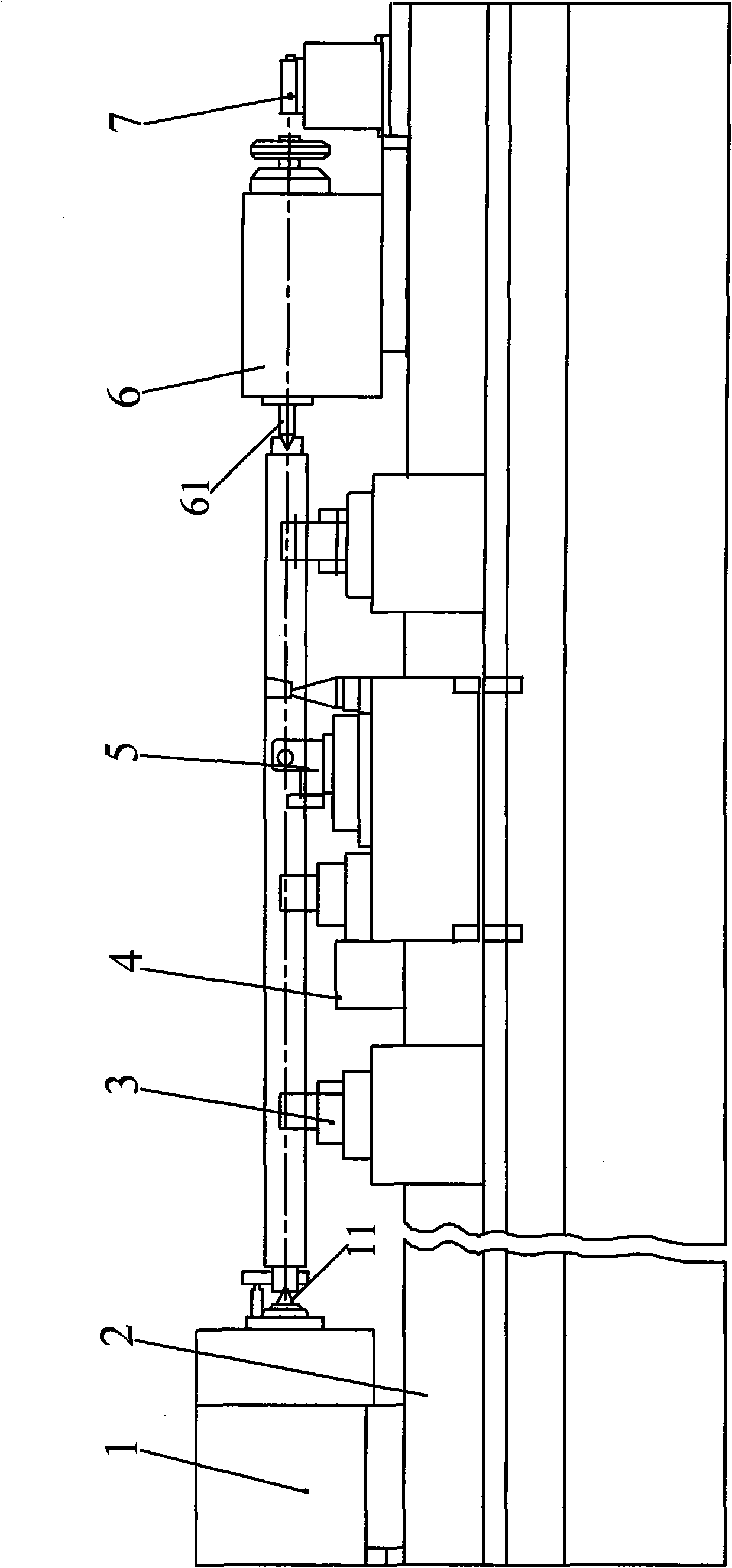

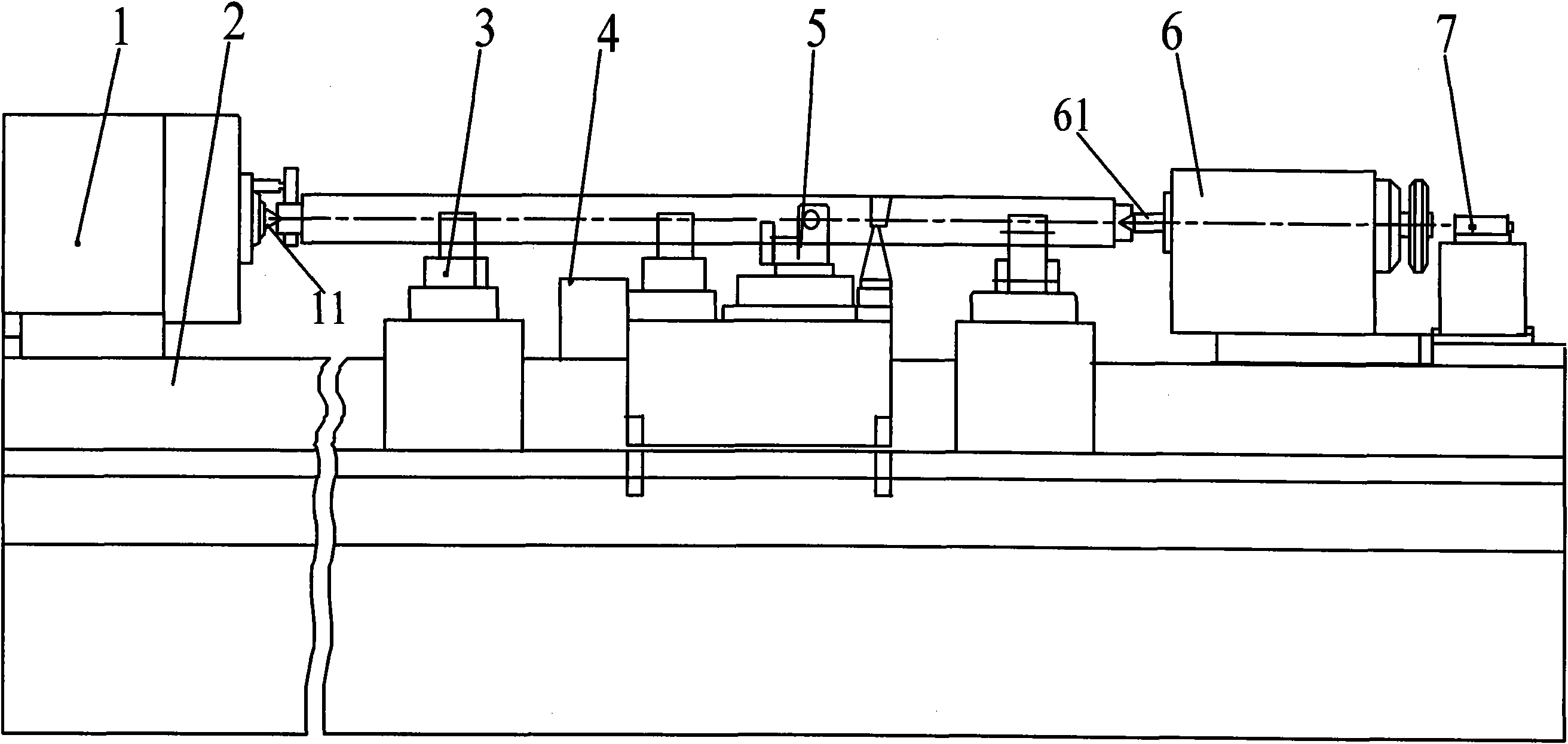

[0026] like figure 1 As shown, the laser pitch measuring instrument of the ball screw of the present invention comprises a spindle box 1, a support 2, a roller support mechanism 3, a damping mechanism 4, a tracking measurement mechanism 5, a tailstock 6 and a laser emitting mechanism 7, the spindle box 1, the tailstock The frame 6 and the laser emitting mechanism 7 are fixed on the machine base 2, and the roller support mechanism 3, the damping mechanism 4 and the tracking measurement mechanism 5 are slidably matched with the machine base 2 through a slide plate, that is, the roller support mechanism 3, the damping mechanism 4 and the tracking measurement mechanism 5 can slide axially relative to the machine base 2, the mutual movement between the machine base 2 and the slide plate is the air-floating static...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com