Electrostatic spinning preparation method of ceramic nanometer composite fibers

A nano-composite fiber and electrospinning technology, which is applied in the field of material manufacturing, can solve the problems of not being able to meet the diversity of scientific research and production, fewer types of ceramic nano-composite fibers, and more restrictions on the selection of raw materials, so as to meet the requirements of scientific research and production diversity. requirements, wide selection conditions, and a wide range of options

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

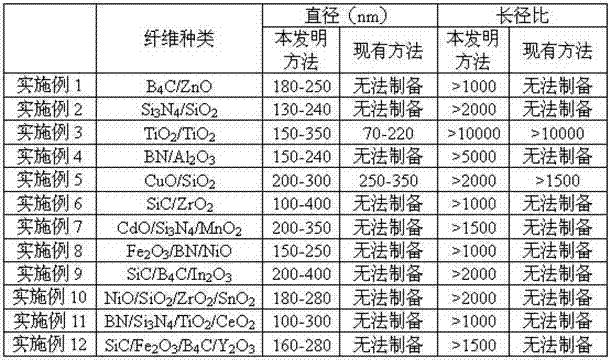

Examples

Embodiment 1

[0030] By volume percentage, take the boron carbide (B 4 C) 3% of nanoparticles, 15% of zinc acetate, 10% of polyvinyl alcohol (referred to as PVA), 72% of deionized water, and 100% of the total volume. PVA is added into deionized water, heated in a water bath and magnetically stirred to obtain a PVA solution with a certain viscosity. Then dissolve zinc acetate in the PVA solution, heat, stir and age for 2 hours to obtain a zinc acetate / PVA solution with uniform composition. then B 4 C nanoparticles were added to the zinc acetate / PVA solution, stirred continuously for 1h, and then the mixed solution was ultrasonically dispersed for 0.5h, and swelled at constant temperature for 0.5h to form B with uniform composition. 4 C / zinc acetate / PVA spinning solution. The spinning solution was poured into a syringe, and the flattened injection needle was used as a capillary for jetting fine flow. During the electrospinning process, the voltage was 40kV, the collection distance was 10cm...

Embodiment 2

[0033] By volume percentage, silicon nitride (Si) with a particle size of 300nm 3 N 4) nanoparticles 4%, tetraethyl orthosilicate 8%, polyvinylpyrrolidone (PVP) 5%, isopropanol 83%, the total volume is 100%. Add polyvinylpyrrolidone (PVP) into isopropanol, heat in a water bath and stir magnetically to prepare a PVP solution with a certain viscosity. Then dissolve ethyl orthosilicate in PVP solution, heat, stir and age for 12 hours to obtain ethyl orthosilicate / PVP solution with uniform composition. Si 3 N 4 Add the nanoparticles into the solution, keep stirring for 1 h, then ultrasonically disperse the mixed solution for 0.5 h, and swell at constant temperature for 0.5 h to form Si with uniform composition. 3 N 4 / tetraethyl silicate / PVP spinning solution. Pour the spinning solution into the syringe, and use the flattened injection needle as the capillary for jetting fine flow. During the electrospinning process, the voltage is 10kV, the collection distance is 30cm, the ...

Embodiment 3

[0036] By volume percentage, titanium oxide (TiO) with a particle size of 30nm 2 ) nanoparticles 8%, butyl titanate 12%, polyvinyl butyral (PVB) 30%, methylene chloride 50%, the total volume is 100%. Add polyvinyl butyral (PVB) into dichloromethane, heat in a water bath and stir magnetically to prepare a PVB solution with a certain viscosity. Then, butyl titanate was added into the PVB solution, heated and stirred and aged for 4 hours to obtain a butyl titanate / PVB solution with uniform composition. TiO 2 The nanoparticles were added to the butyl titanate / PVB solution, stirred continuously for 2 hours, then the mixed solution was ultrasonically dispersed for 0.5 hours, and swelled at a constant temperature for 0.5 hours to form a uniform TiO 2 / Butyl titanate / PVB spinning solution. Pour the spinning solution into the syringe, and use the flattened injection needle as the capillary for jetting fine flow. During the electrospinning process, the voltage is 30kV, the collection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com