Method for preparing ordered nano cuprous oxide polycrystalline powder

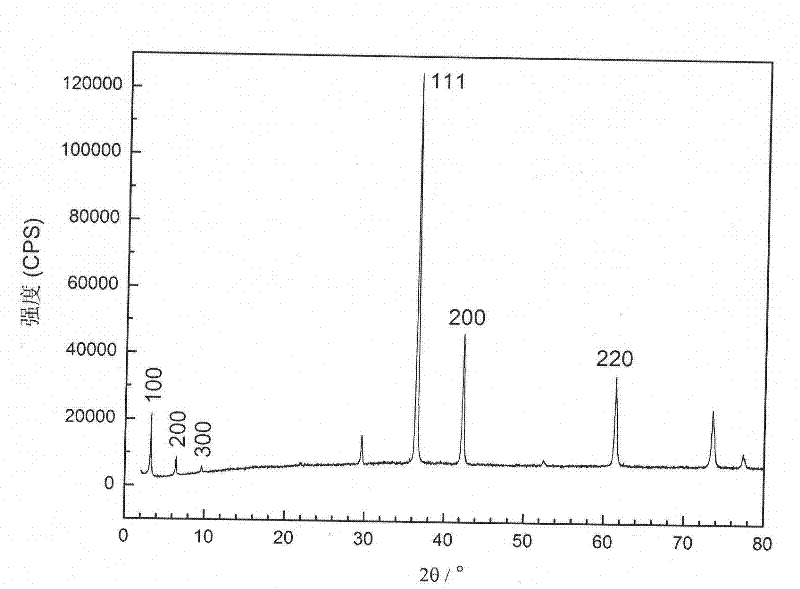

A technology of nano-cuprous oxide and polycrystalline powder, which is applied in the direction of copper oxide/copper hydroxide, etc., can solve the problems of inaccessibility, and achieve the effect of good crystallinity and clear diffraction peaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Dissolve 0.02mol copper chloride in a beaker containing 30mL of water, and dissolve 1g of sodium dodecylsulfonate and 2.4g of glucose in a beaker containing 20mL of ethanol solution to obtain dodecylsulfonate Natrate glucose ethanol solution mixture, then preheat and dissolve it, mix it, put it into a flask with a reflux device, stir evenly, and keep it warm for later use.

[0034] (2) Dissolve 1.6g of sodium hydroxide in 30mL of water, then add 10mL of ethanol to prepare a sodium hydroxide-ethanol-water-alcohol mixture for use.

[0035] (3) Preheat and dissolve the mixed solution prepared in step (2), quickly add it to the flask in step (1), raise the temperature to reflux temperature under nitrogen protection, reflux for 48 hours, stop stirring and heating.

[0036] (4) Let the product obtained in the previous step stand at room temperature for 15 hours to obtain a brick-red precipitate, then wash it with deionized water three times, and then filter it with suctio...

Embodiment 2、 example 3、 example 4、 example 5

[0040] Change the time of reflux to 7h, 12h, 24h, 36h respectively in the operation in the step (3) in the embodiment 1, other each operation is all the same with the embodiment 1, obtains the product with the embodiment 1.

Embodiment 6

[0042] Step (1) C in embodiment 1 6 h 12 o 6 Change the consumption of 1.8g into 1.8g, other steps are with embodiment 1, obtain product with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com