Cylinder head for piston refrigeration compressor, compression unit including such cylinder head, and piston refrigeration compressor including said compression unit

A technology for refrigeration compressors and compression units, which is applied to the components of pumping devices for elastic fluids, machines/engines, liquid volumetric machines, etc., can solve problems such as bulkiness, reduce processing time, improve performance, The effect of precise geometric dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

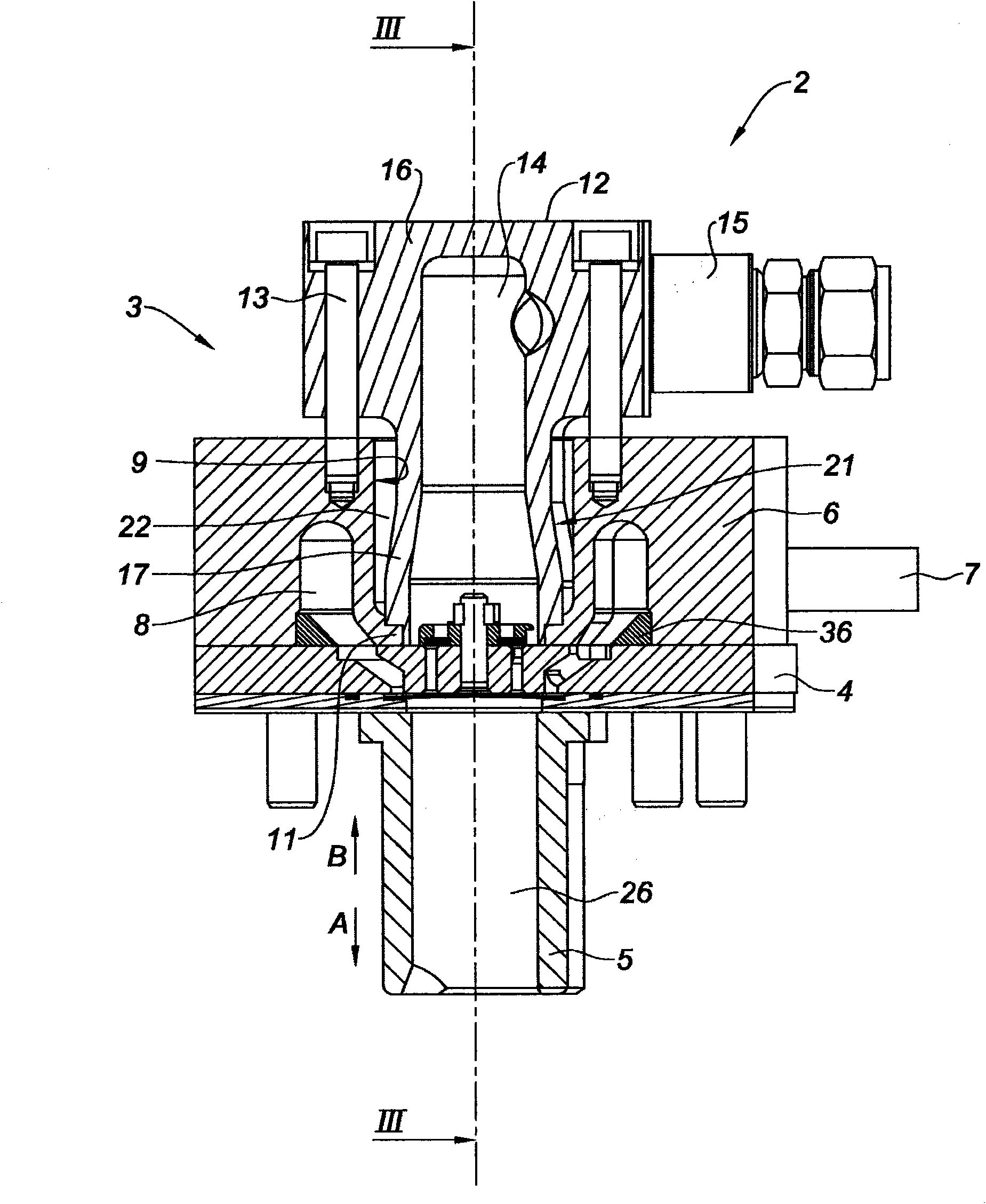

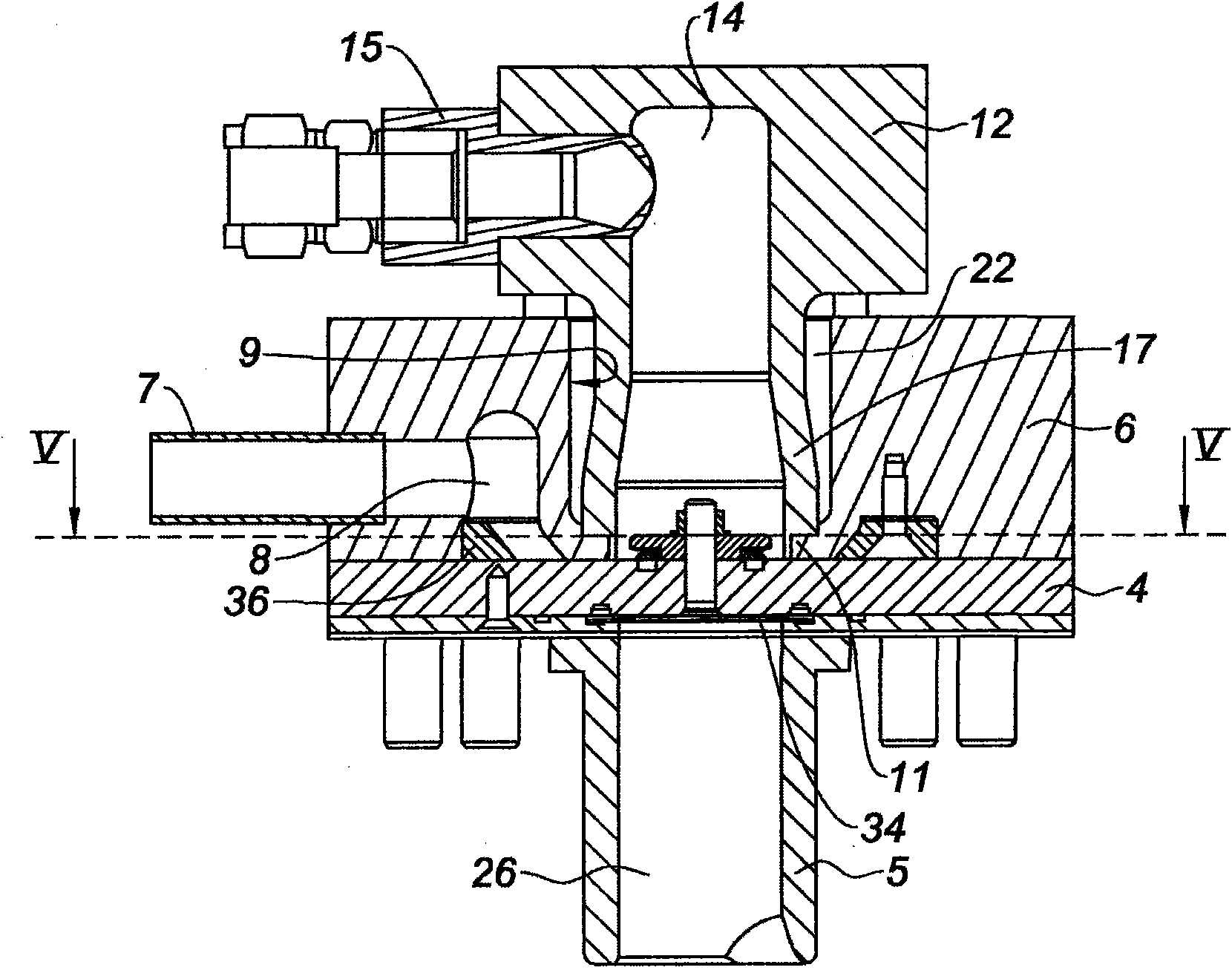

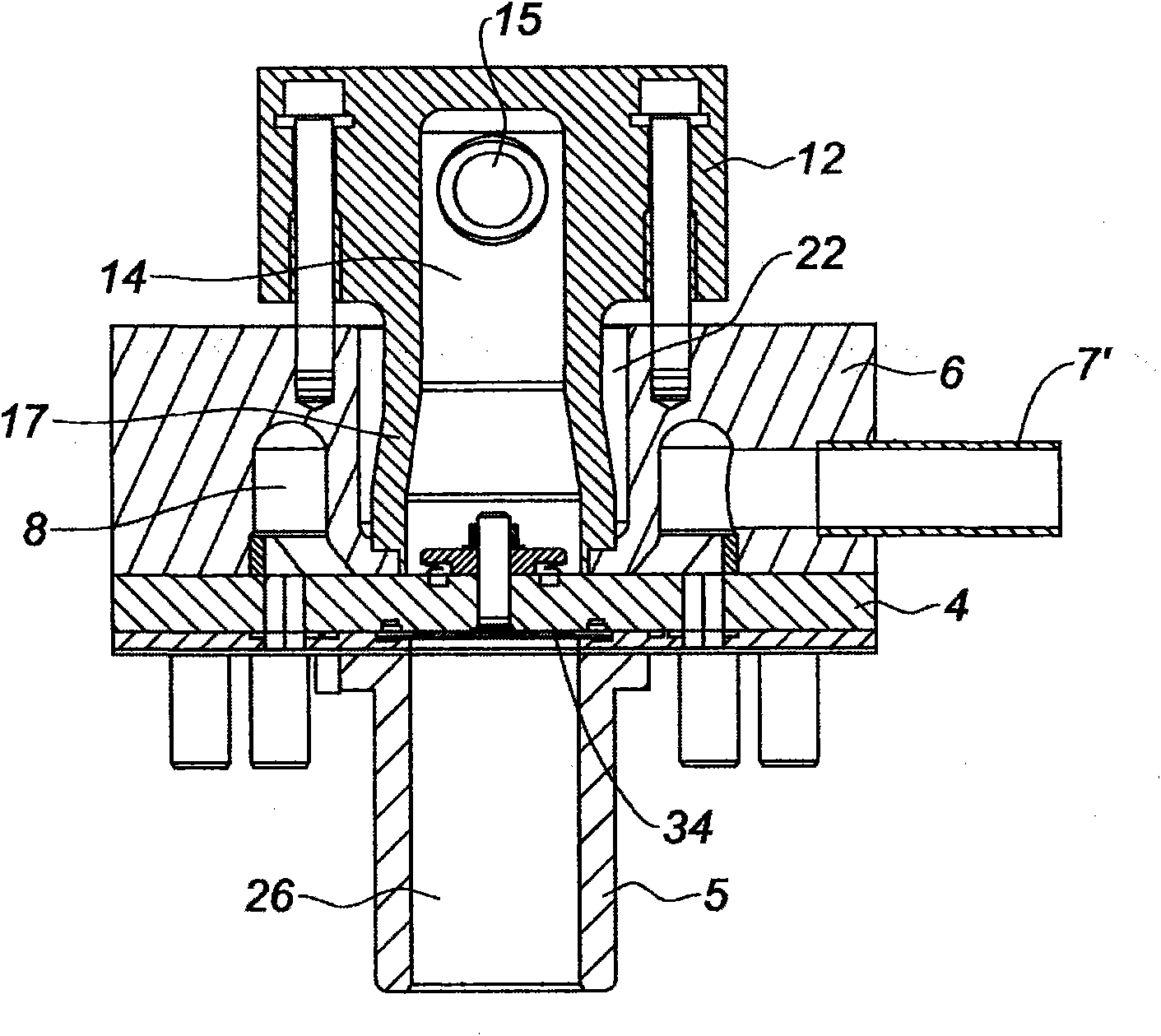

[0029] The compression unit 2 includes a cylinder head 3, a valve plate 4 and a cylinder block 5, only the cylinder block 5 is shown in the figure.

[0030] The cylinder head 3 comprises a first substantially cylindrical part 6 . The first part 6 is fastened to the valve plate 4 . The first part 6 comprises two radial cooling gas inlets 7, 7' and defines a generally annular cooling gas suction chamber 8, to which the radial cooling gas inlets 7, 7' communicate.

[0031] The first part 6 comprises an axial channel 9 delimited by the cylindrical surface.

[0032] On its surface facing the valve plate 4 , the first part 6 has a radial flange 11 , which is directed towards the inside of the channel 9 , the flange 11 extending over the entire circumference of the channel 9 .

[0033] The cylinder head 3 comprises a second part 12 axially fastened to the first part 6 by means of screws 13 . The assembly by fastening the second part 12 on the first part 6 enables a certa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com