Fixing device and projector of optical engine

A technology of optical engines and fixtures, used in optics, projection devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

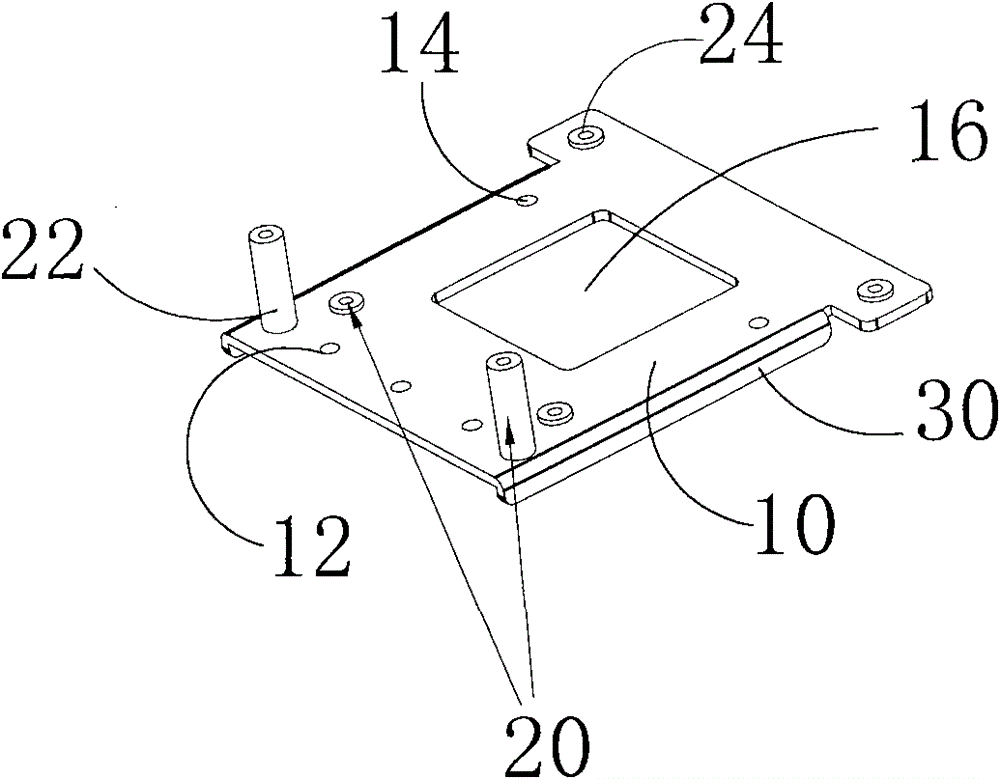

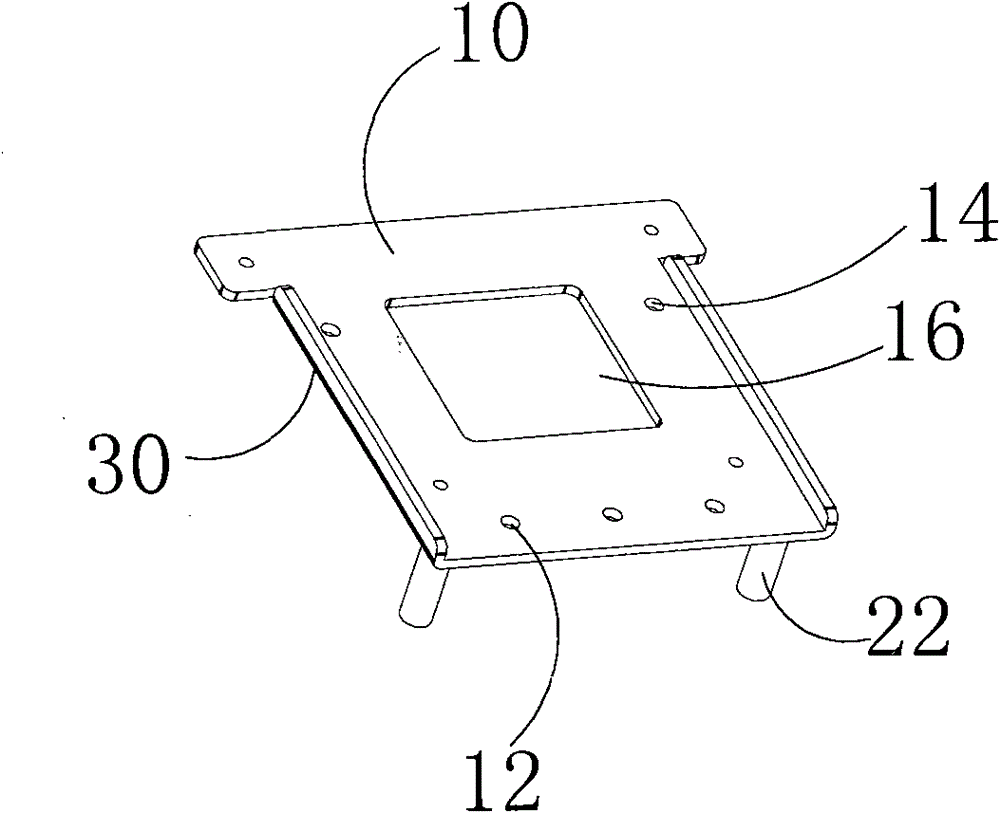

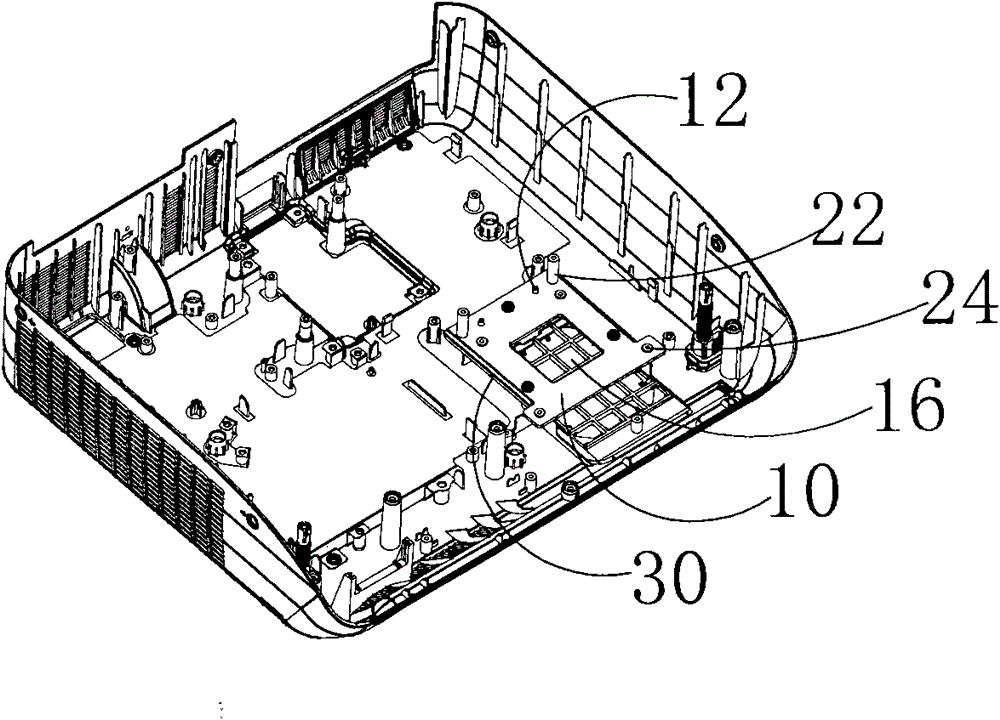

[0019] The substrate 10 is provided with mounting posts 12 and mounting screw holes 14, wherein two mounting posts 12 are provided for positioning during installation of the optical engine fixing device, and 3 mounting screw holes 14 are provided in triangular distribution, and pass through the corresponding Three screws are installed inside the projector housing.

[0020] The studs 20 include elongated studs 22 and flat studs 24 for fixing the optical engine. The folded edges 30 are disposed on both sides of the substrate 10 to enhance the strength of the substrate 10 . Because the two sides of the optical engine fixing device have folded edges for reinforcement, it is difficult to deform in the longitudinal direction, preventing the deformation of the optical engine caused by the deformation of the sheet metal itself.

[0021] like image 3 , Figure 4 As shown, the projector includes a casing 100, an optical engine 200, a liquid crystal panel cooling air duct assembly 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com