Electrode piece loading device for power lithium battery

A lithium battery and pole piece technology, which is applied in the field of pole piece feeding devices, can solve the problems that product quality cannot be guaranteed, manual positioning and feeding cannot meet production capacity requirements, etc., and achieves low cost, improved positioning accuracy, and shortened positioning time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

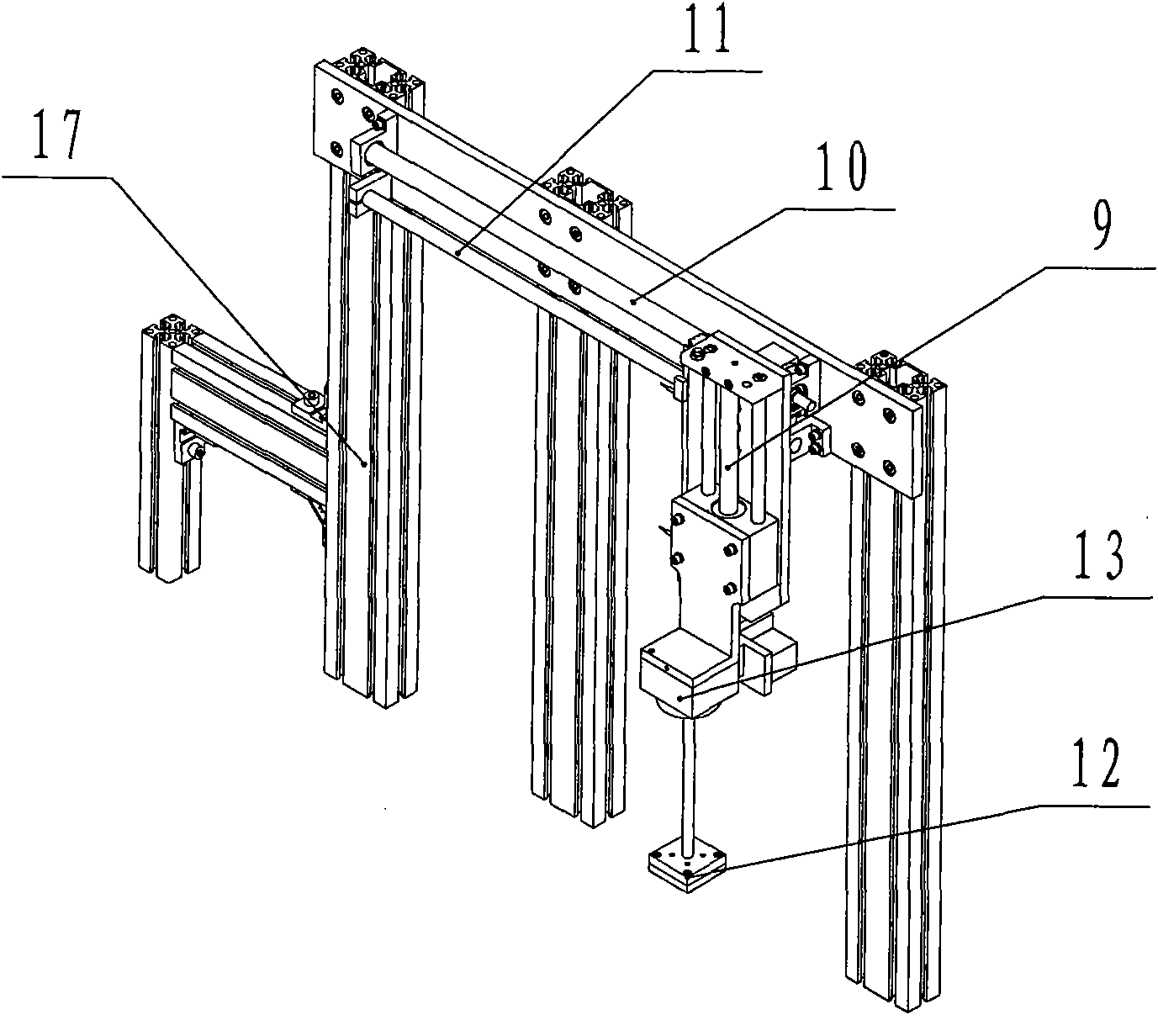

[0014] A pole piece feeding device applied to a power lithium battery, comprising a positive and negative pole piece shaping mechanism and a positive and negative pole piece conveying mechanism, the positive and negative pole piece shaping mechanism includes a bracket 1 and positive and negative poles fixed on the bracket 1 placed in the left and right directions The feeding table 2 of the sheet, under each feeding table 2, there are left and right screw rods 3 in the front and rear directions and left and right directions. The bottom surface of the table 2 is fixed around, and the feeding table 2 is provided with elongated holes 6 at the positions vertically corresponding to the left and right screw rods 3, and the baffle plates 7 positioned at both sides of the left and right screw rods are worn in the elongated holes 6. The plate 7 is fixed with a nut 8 that is sleeved on the left and right screw rods 3; the positive and negative plate conveying mechanism includes a base 17 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com