Variable-height continuous steel truss girder railway bridge inspection vehicle

A steel truss girder and variable height technology is applied in the field of inspection vehicles of variable height continuous steel truss girder railway bridges, which can solve problems such as difficulty in maintenance, lack of climbing function, and difficulty in stable lifting and lowering of the maintenance gondola during safe operation.

Active Publication Date: 2010-11-24

CHINA RAILWAY ERYUAN ENG GRP CO LTD

View PDF5 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The bridge maintenance vehicles widely used in China at this stage are mainly used for flat-chord steel beams and do not have the function of climbing

The upper chord of the Ganjiang East New Super Bridge is in the form of variable-height continuous steel truss girders. The basic truss height is 19m, the maximum truss height exceeds 35m, and the slope reaches 35%. According to the structure type of the bridge, its maintenance equipment can not only move on the flat chord , must also have the ability to climb slopes. Such a large truss height and slope make it very difficult for safe operation and stable lifting of the inspection gondola. Moreover, the inspection range of the upper-string inspection vehicle is very large, and it is very difficult to inspect all positions.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

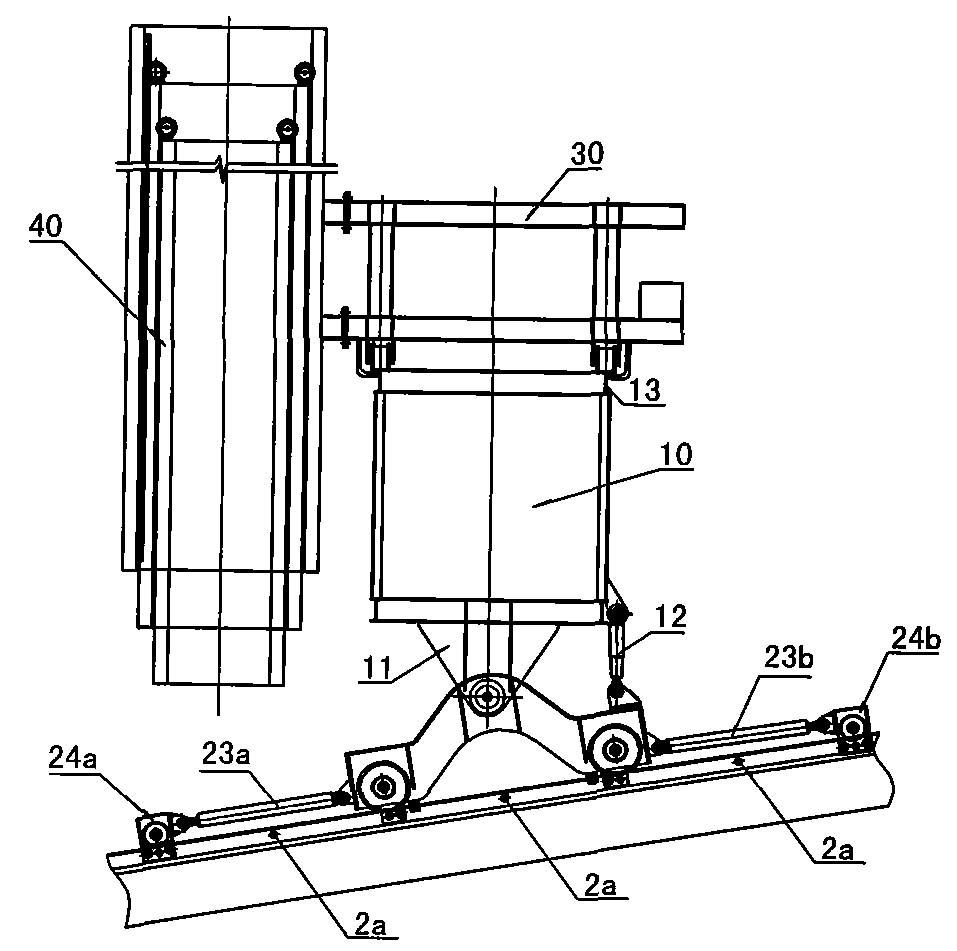

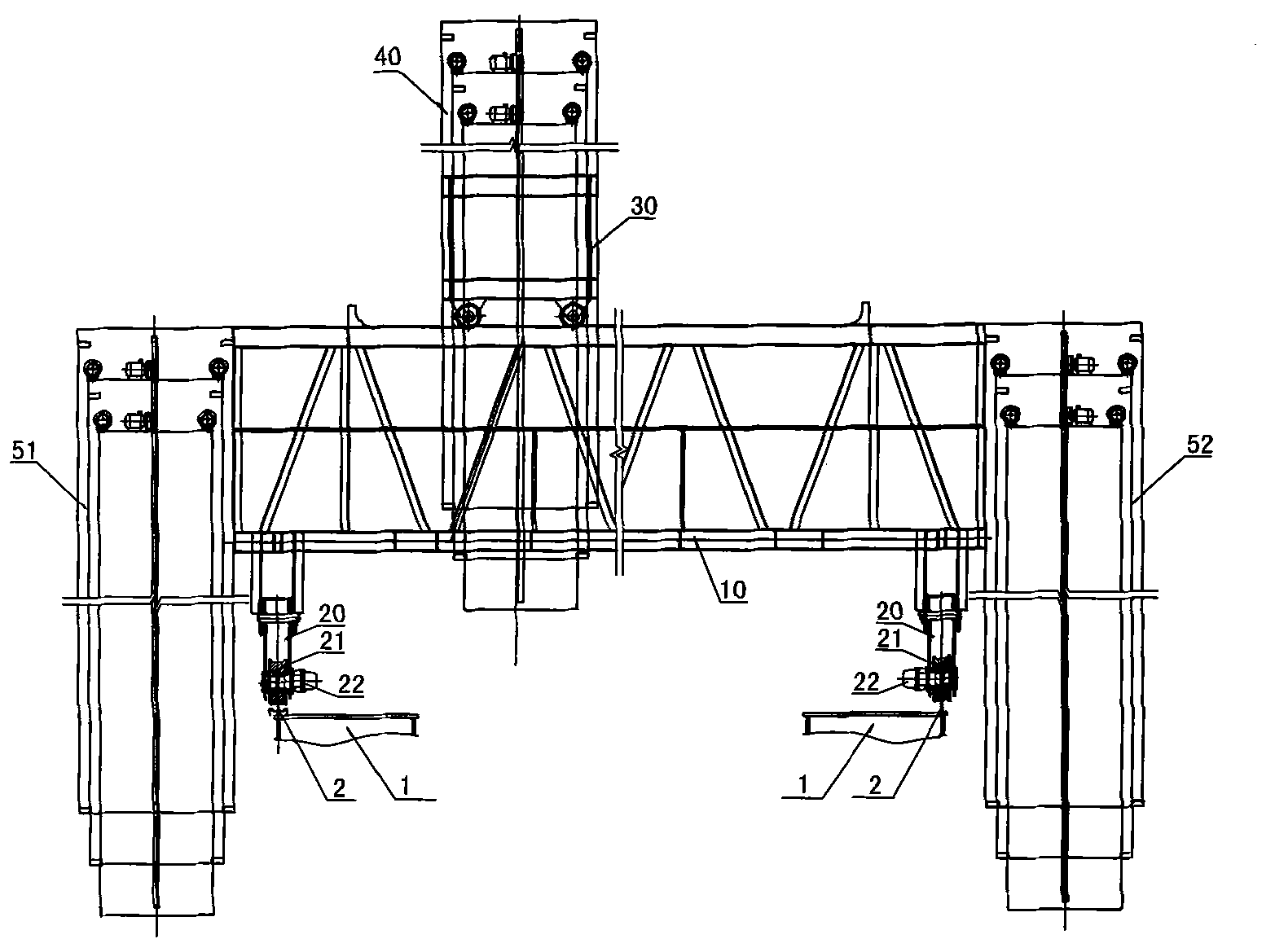

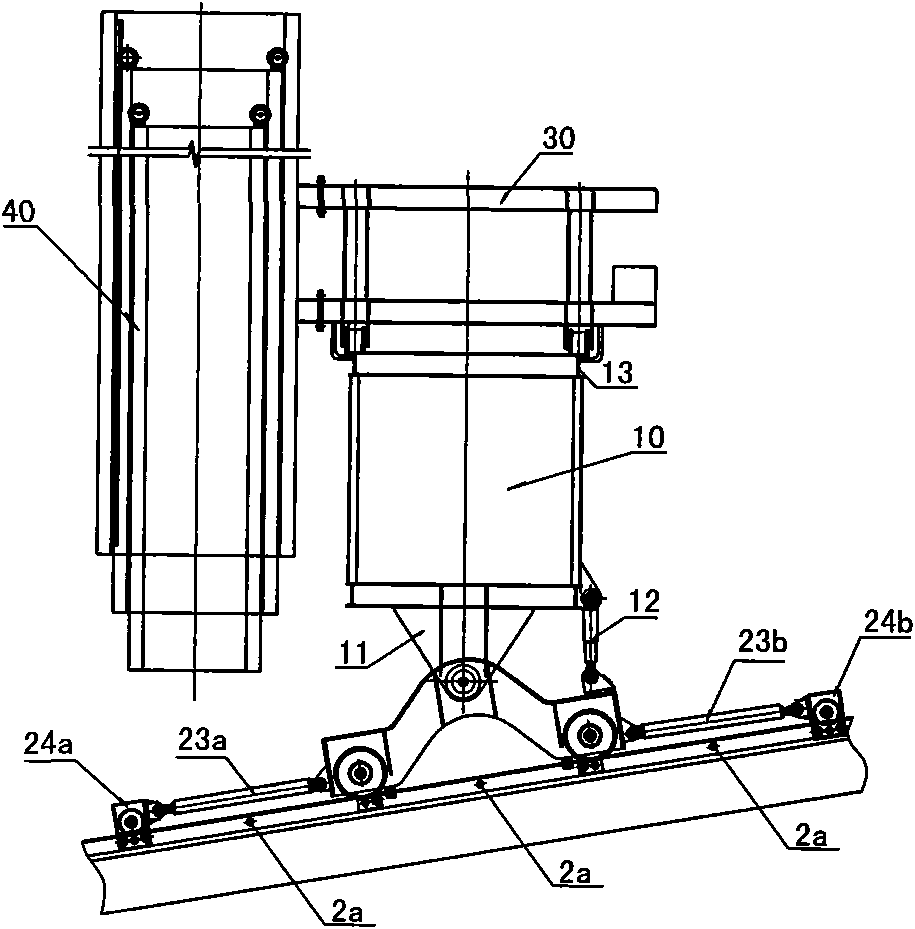

The invention discloses a variable-height continuous steel truss girder railway bridge inspection vehicle, aiming at realizing arch climbing and straddle walk and conveniently inspecting and repairing each part of a girder. The railway bridge inspection vehicle comprises a repair main truss (10) which steps over a steel truss girder cross the surface of a bridge and a running gear which drives the repair main truss (10) to move along rails (2) which are paved on top booms (1) of the steel truss girder in the direction of the bridge, wherein a repair workbench is arranged on the repair main truss (10), the running gear is formed by combining a motor-driven running gear and a hydraulic-driven walking type running gear, and locking devices are respectively arranged between the motor-driven running gear or the hydraulic-driven walking type running gear and the rails (2). The railway bridge inspection vehicle can realize the arch climbing and straddle walk, and the repair work of the whole bridge can be finished only by one inspection vehicle, thereby providing guarantee for daily inspection and maintenance. The inspection vehicle has simple structure, novel form, safety and reliability and higher automation, prevents operation staffs from operating on the top booms as much as possible, and greatly increases the safety of construction operations.

Description

Variable height continuous steel truss girder railway bridge inspection vehicle technical field The invention relates to a railway bridge inspection vehicle, in particular to an inspection vehicle for a variable-height continuous steel truss girder railway bridge. Background technique In order to ensure the safety of bridges and traffic, bridge maintenance and repair is an essential work, and the related supporting maintenance equipment is an important guarantee for maintenance and repair construction. Safe and reliable maintenance equipment can properly solve bridge inspection and maintenance problems, and provide safe and reliable construction and maintenance methods for bridges in the later stage of construction and after they are put into operation. At present, the general maintenance method in foreign countries is to occupy the line and use large-scale maintenance equipment to repair the bridge. However, in my country, the railway traffic density is high, especially ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B61D15/08E01D22/00

Inventor 马庭林鄢怀斌陈思孝王员根戴胜勇杨善奎袁明艾宗良胡步毛童登国刘名君唐向东朱东明梁辉

Owner CHINA RAILWAY ERYUAN ENG GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com