Full-load static characteristic test device and test method of bolt joint surface unit

A technology of bolt joint surface and test device, which is applied in the direction of measuring device, strength characteristic, material inspection product, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

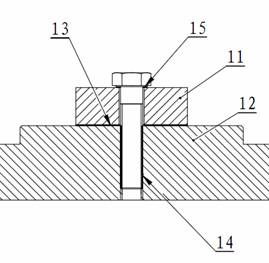

[0041] Such as figure 1 As shown, the unit properties of the bolt joint surface consist of the joint surface of two components A11 and component B12 (joint surface A13), the threaded joint surface of the bolt and one of the member B12 (joint surface B14), and the joint surface of the bolt and the other member A11 (Joining surface C15) is determined by the characteristics of the three-part joint surface.

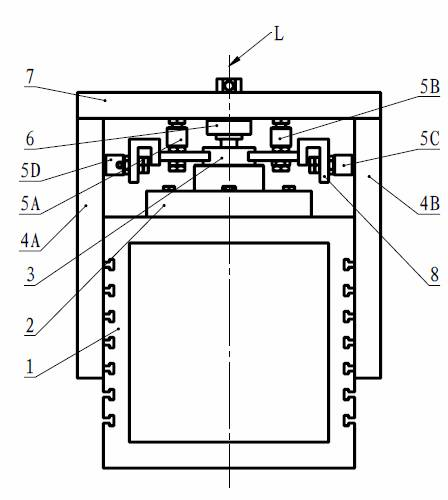

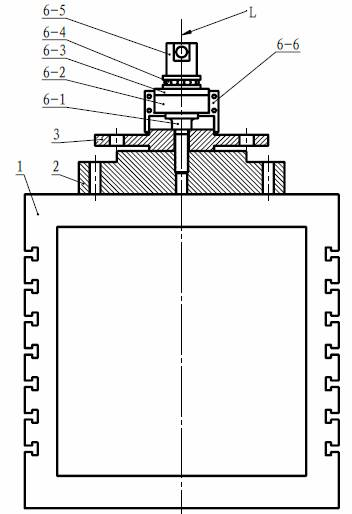

[0042] Such as figure 2 As shown, the structure of the experimental device of the present invention is to include a box body 1, a crossbeam 7 is arranged above the box body 1, and the crossbeam 7 is fixedly connected with the box body 1 by the left column 4A and the right column 4B; There is a lower test piece 2, and an upper test piece 3 is placed on the lower test piece 2, and a preload assembly 6 is arranged between the upper test piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com