Sand-stone separator

A technology of sand and gravel separator and separation cylinder, which is applied in the field of sand and gravel separator, can solve the problems of limited separation effect, environmental pollution, low export, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

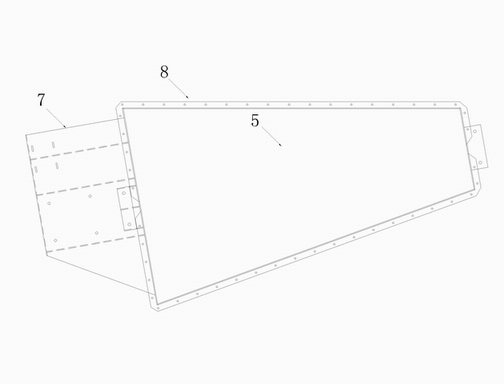

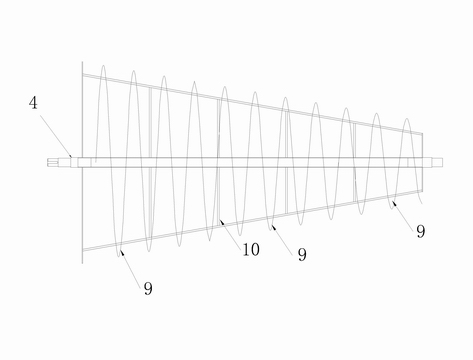

[0031] A sand and gravel separator, comprising a drive motor 1, a conical separation cylinder 5 and a spiral blade 9, the drive motor 1 is connected to one end of the blade shaft 4 through a reduction device 2, and the other end of the blade shaft 4 is connected to the conical separation cylinder 5 rotating connection, the blade shaft 4 is provided with a plurality of helical blades 9 that are conical as a whole, the helical blades 9 are gradually narrowed in the direction of advancement, and the outer cover of the helical blades 9 is provided with a conical separation cylinder 5; the conical separation cylinder 5 The outlet at the front end is connected with the inlet at the rear end of the screening drum 14 correspondingly. The sieving cylinder 14 is a grid-shaped cylinder, and its outlet is placed inclined downwards.

[0032] The cylinder wall rear end feed inlet of sep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com