Accessory belt tensioning device of engine accessory wheel system

A technology of tensioning device and engine, applied in the direction of transmission device, machine/engine, belt/chain/gear, etc., can solve problems such as troublesome adjustment of belt tension, inability to arrange automatic tensioner, and small space for wheel train.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The structure of the present invention is described in detail below in conjunction with accompanying drawing:

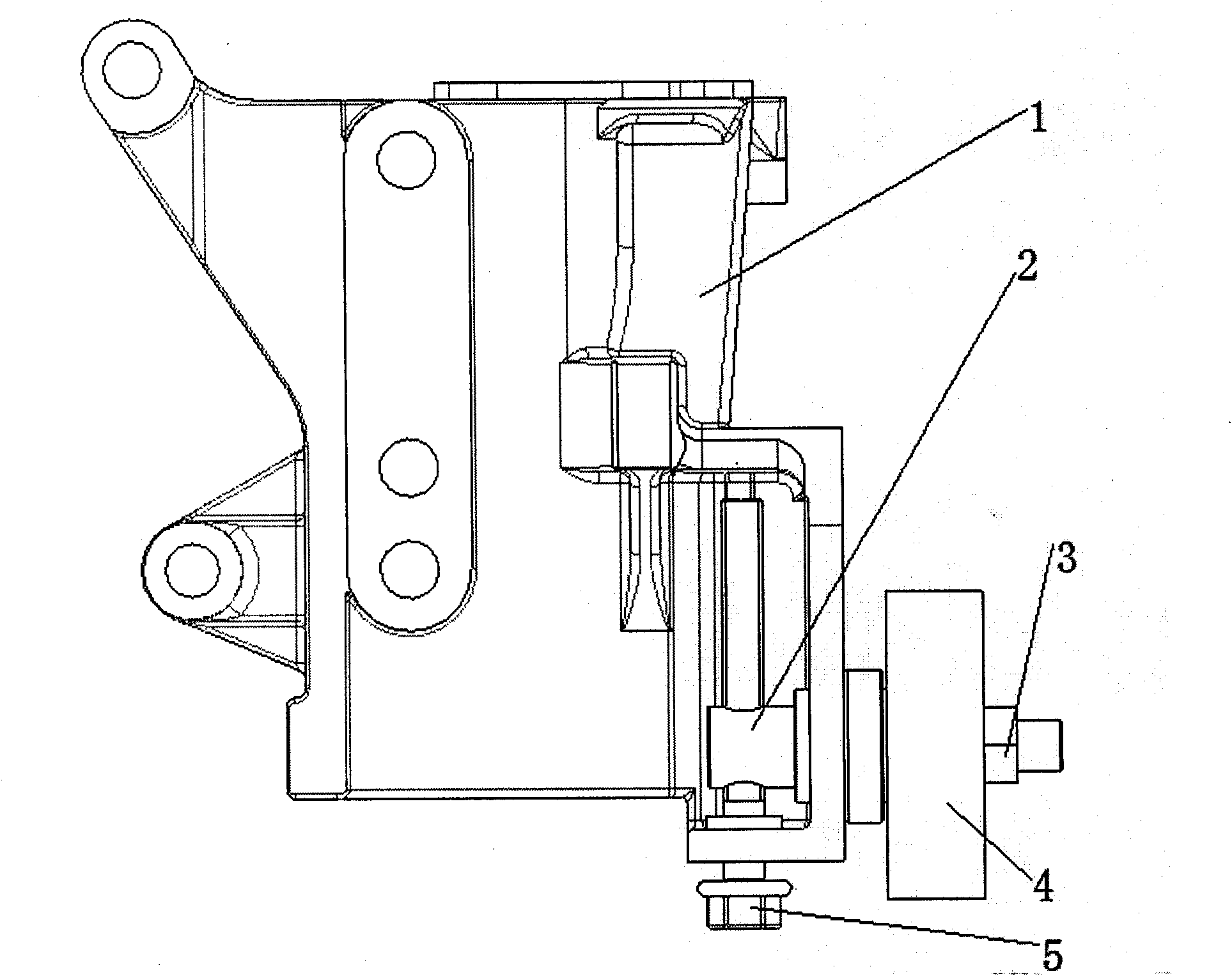

[0019] see figure 1 , the tensioning device is composed of a bracket 1, a shaft bolt 2, a nut 3, a pulley 4 and an adjusting bolt 5, wherein:

[0020] For the structure of bracket 1, see figure 2 , the base frame part of the bracket 1 has a bolt hole 13 connected with the engine body, a pulley installation part 14 is arranged on the bracket 1, and a shaft bolt installation plane parallel to the central plane of the accessory wheel train is arranged on the pulley installation part 14, and The two ends of the belt pulley installation part 14 are provided with an adjusting screw installation part bent 90 degrees inward, a waist-shaped groove 11 is arranged on the shaft bolt installation plane, and a U-shaped slot hole 12 is arranged at the lower end. The effect of waist groove 11 is: 1, limited the adjusting range of belt pulley, the range that axle bolt 2 mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com