Pulping method

A technology for pulping and pulping materials, applied in dairy products, milk substitutes, applications, etc., can solve the problems of low content of fishy substances and light beany smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

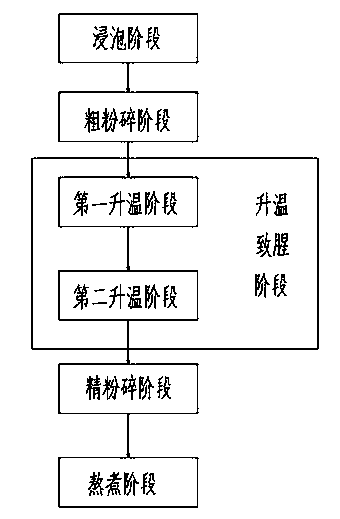

[0019] Such as figure 1 As shown, the pulping method as an embodiment of the present invention includes a soaking stage, a coarse crushing stage, a temperature rise stage, a fine crushing stage, and a boiling stage, wherein the liquid temperature in the coarse crushing stage is T1, and T1≤ 70°C.

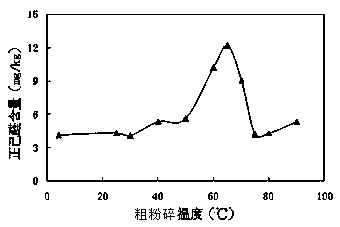

[0020] figure 2 The relationship between the amount of n-hexanal produced in the slurry and the temperature T1 in the coarse pulverization stage is shown. The content of n-hexanal represents the content of fishy substances such as hexanal. Experiments have proved that under certain other conditions, when the liquid temperature T1 is about 65°C, the chemical reaction rate between lipoxygenase and unsaturated fatty acid is the fastest, which is most conducive to the formation of fishy substances such as hexanal. The beany flavor of the soya-bean milk that makes is the strongest. When liquid temperature T1 was greater than 70°C, the chemical reaction rate between lipoxygenase and u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com