Integrated push rod seal assembly

A sealing component and integrated technology, applied in the field of industrial regulating valve actuator sealing components, can solve the problems of difficult O-ring replacement, valve failure, easy aging of fluorine rubber, etc., to achieve safe and reliable sealing structure, reduced accident rate, The effect of improved adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

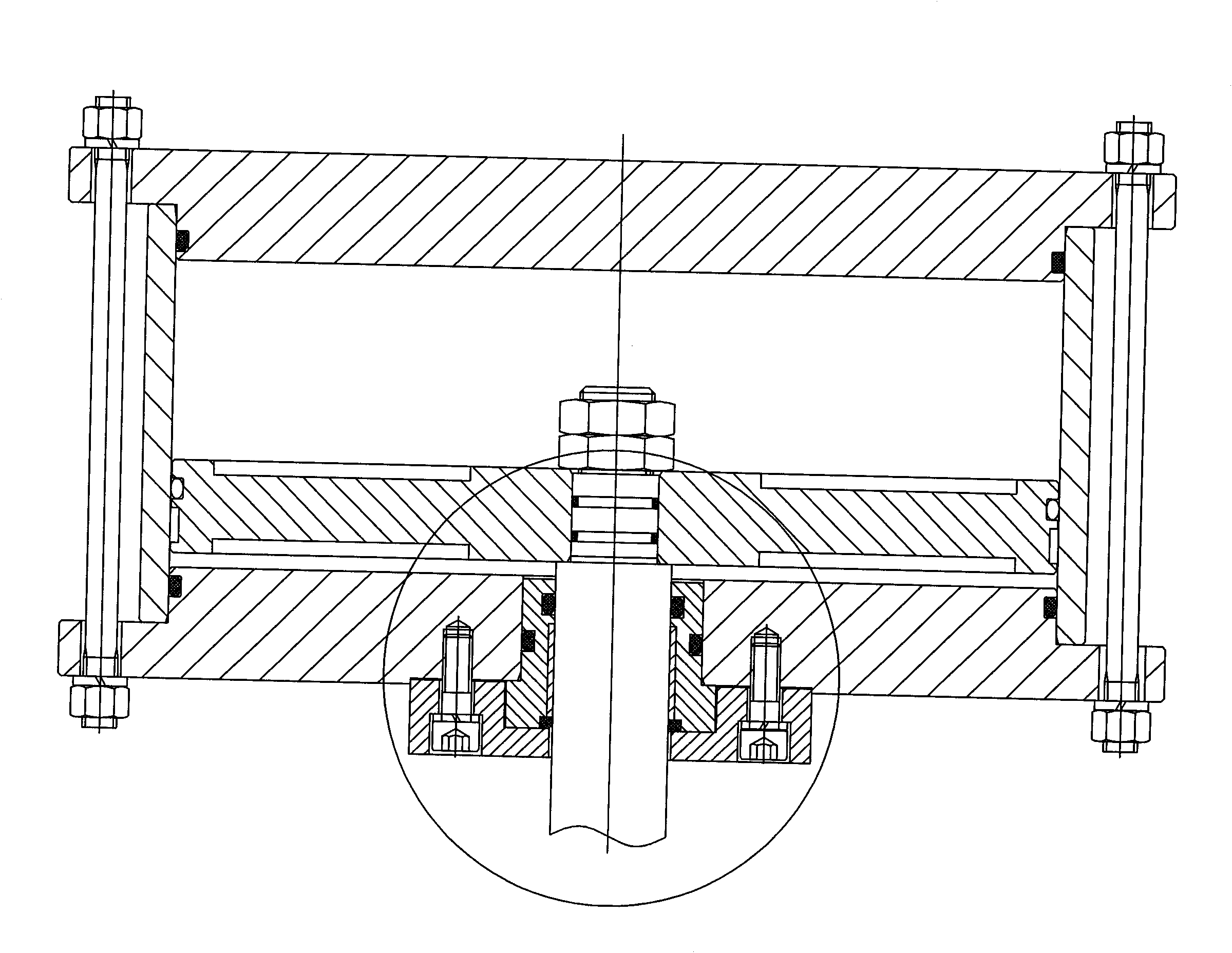

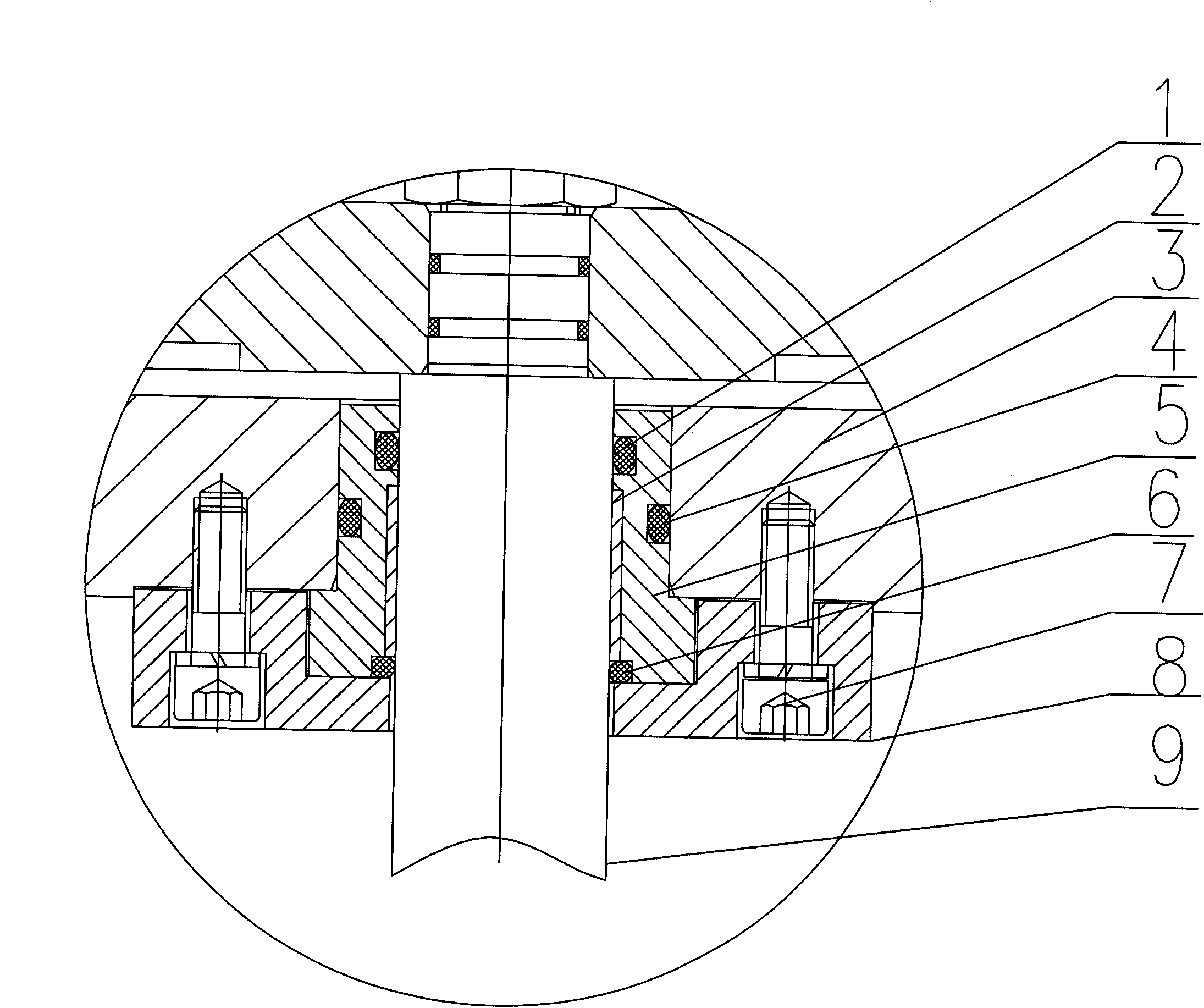

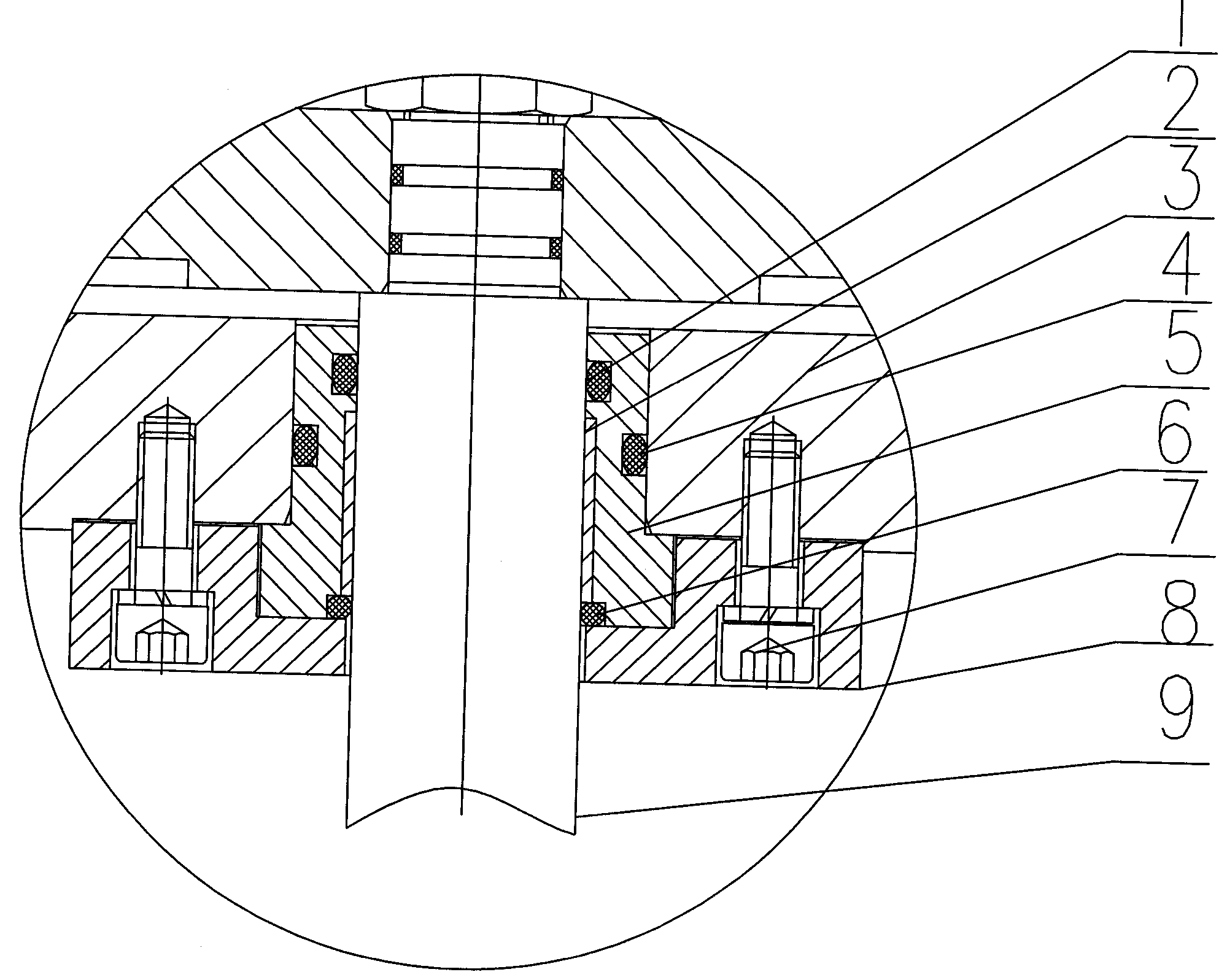

[0012] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

[0013] Such as figure 2 As shown, the integrated push rod seal assembly is composed of inner O-ring 1, sliding bearing 2, cylinder head 3, outer O-ring 4, shaft sleeve 5, dust-proof ring 6, screw 7, pressure plate 8 and push rod 9 components .

[0014] The inner O-ring 1, sliding bearing 2, and outer O-ring 4 of the sealing assembly are embedded in the shaft sleeve 5 in an integrated manner, assembled into the cylinder head 3 as a whole, and the dustproof ring 6 is installed, and the shaft is pressed by the pressure plate 8 Set 5, use screw 7 to fix the pressure plate 8 on the cylinder head 3,

[0015] The sealing system of the sealing assembly is assembled by three sealing structures of an inner O-ring 1 , an outer O-ring 4 and a dustproof ring 6 . The inner O-ring 1 is installed between the shaft sleeve 5 and the push rod 9, which is the first se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com