Control device of rolling machine and control method thereof

A technology of a control device and a control method, which is applied to the rolling mill control device, metal rolling, metal rolling, etc., can solve the problems of large fluctuation and large time constant of the plate thickness change on the delivery side, and achieve the effect of suppressing the plate thickness fluctuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

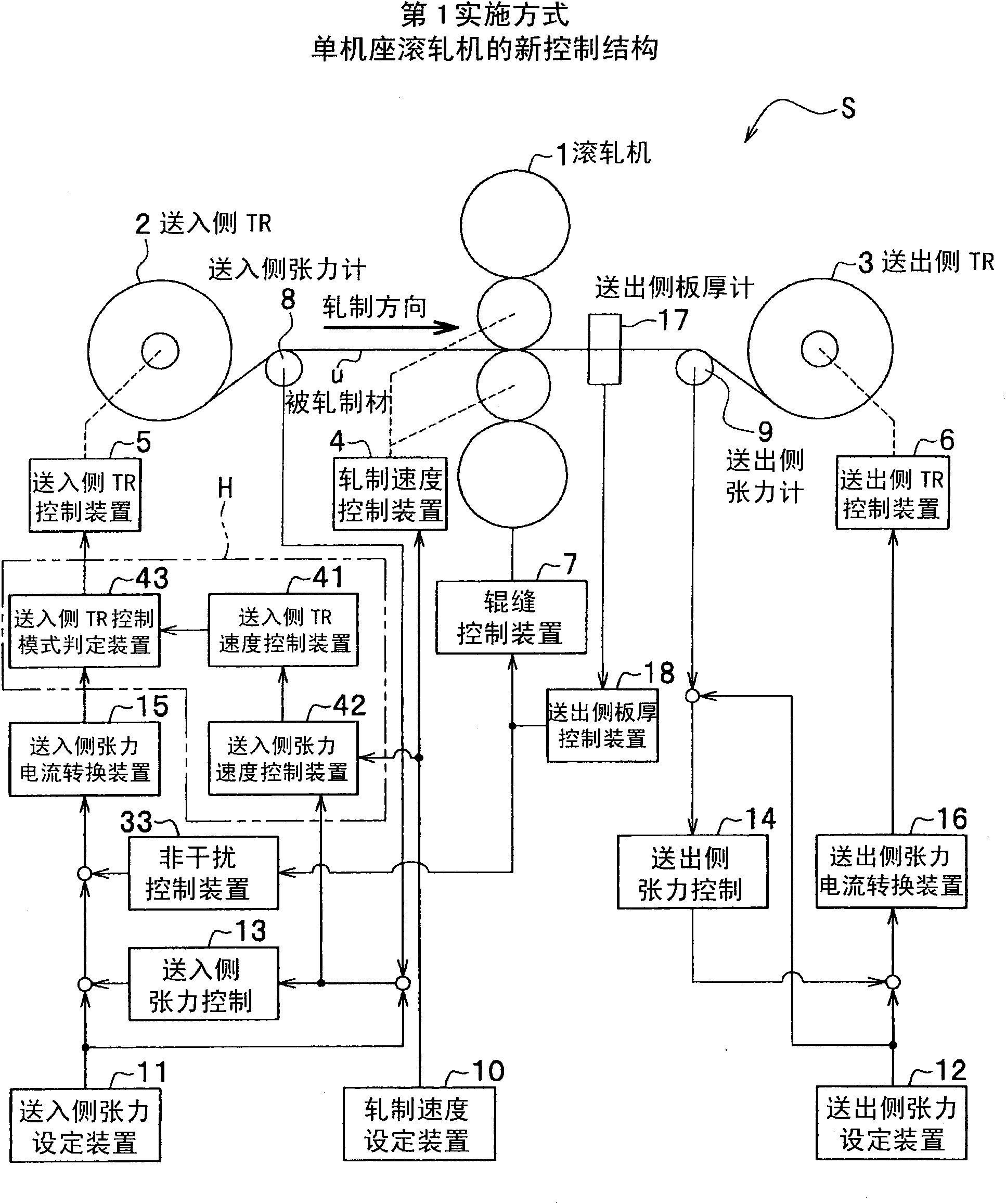

[0080] (Outline of Single Stand Rolling Mill S)

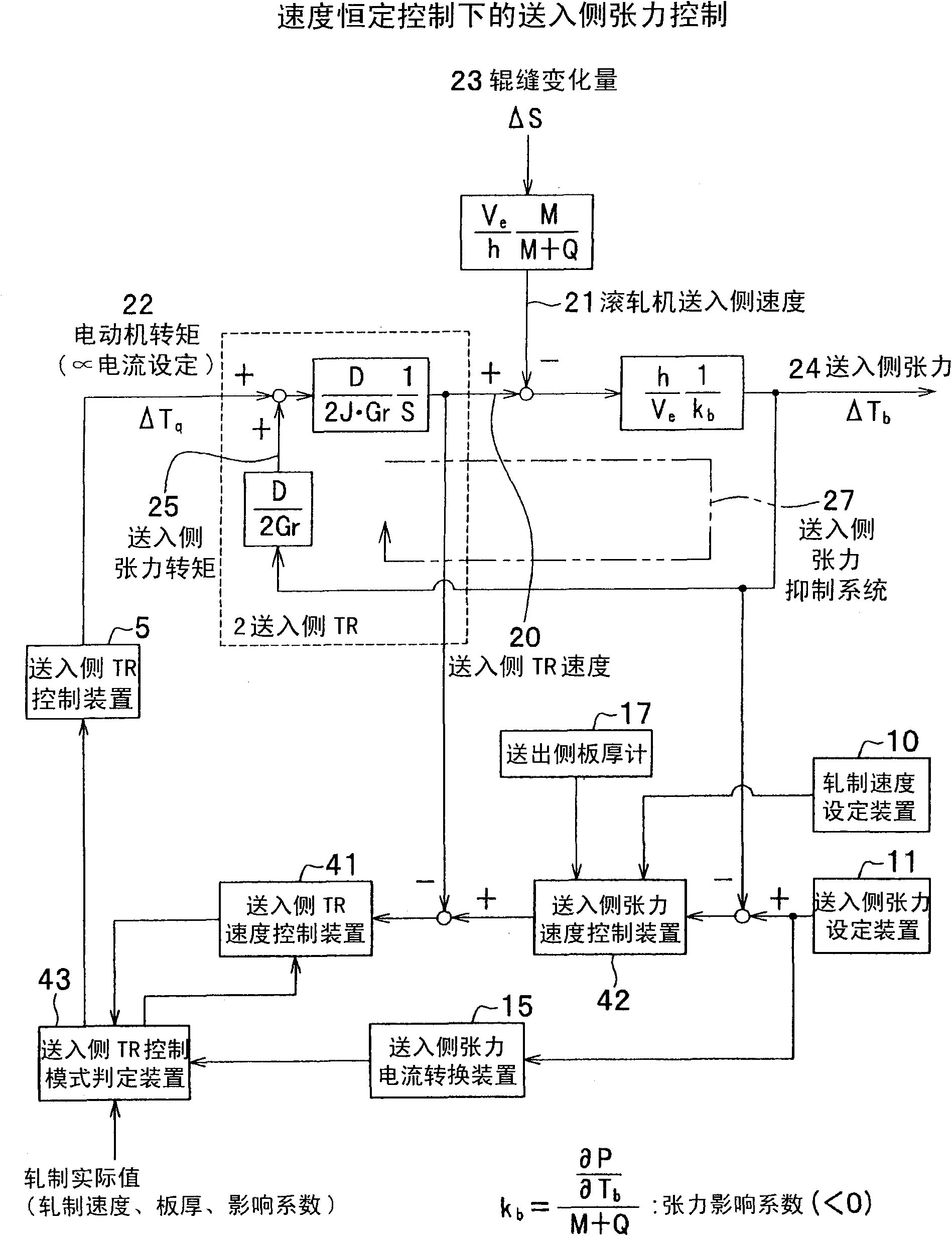

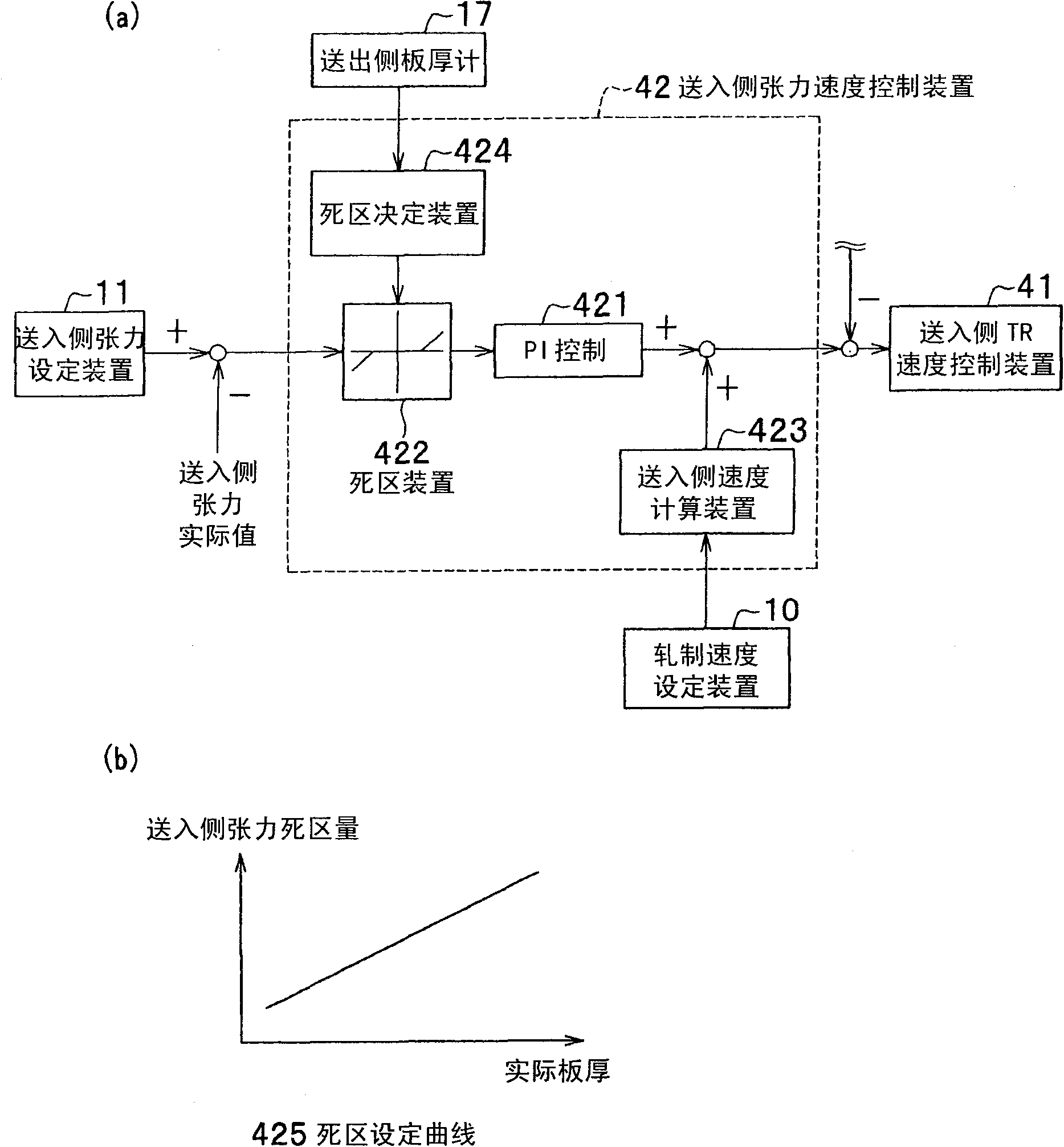

[0081] In the single-stand rolling mill S of the first embodiment, the tension reel on the sending side (hereinafter referred to as the sending side TR2) is controlled by constant speed control, and the rolling machine is controlled by the tension control with the speed of the tension reel as the control end. 1 The tension of the rolled material u on the feeding side is controlled. In this tension control, a dead band is provided in the tension deviation to be controlled to control the speed variation of the delivery side TR2 so as to minimize the thickness deviation of the delivery side of the rolled material u.

[0082] That is, the sending-side TR2 is controlled at a constant speed, and the speed of the sending-side TR2 is suppressed from fluctuating with tension fluctuations.

[0083] In addition, when the thickness variation (product thickness variation) of the delivery side of the rolled material u is large, the constant...

no. 2 Embodiment approach

[0132] Next, use Figure 6 A single-stand rolling mill according to a second embodiment will be described.

[0133] in addition, Figure 6 It is a diagram showing the control structure when the entry TR2 is controlled by the entry TR speed 20 in the single-stand rolling mill having no tensiometers on the entry side and the exit side of the rolling mill according to the second embodiment.

[0134] In the single-stand rolling mill of the second embodiment, the feeding-side / delivery-side tensiometers 8, 9 for measuring the actual tension are not provided on the feeding-in side and the sending-out side of the rolling mill 1 (refer to figure 1 )Case.

[0135] There is no tension meter for measuring the actual tension on the feed-in side and the send-out side of the single-stand rolling mill, such as Figure 6 As shown, because at the moment when the motor torque 22 is consistent with the tension torque 25 of the feeding side, the change of the TR speed 20 of the feeding side is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com