Three-way pipe used in control pipelines for evaporation emission of fuel oil

An evaporative emission and pipeline control technology, which is applied in the field of three-way pipes to avoid air blockage, work reliably and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

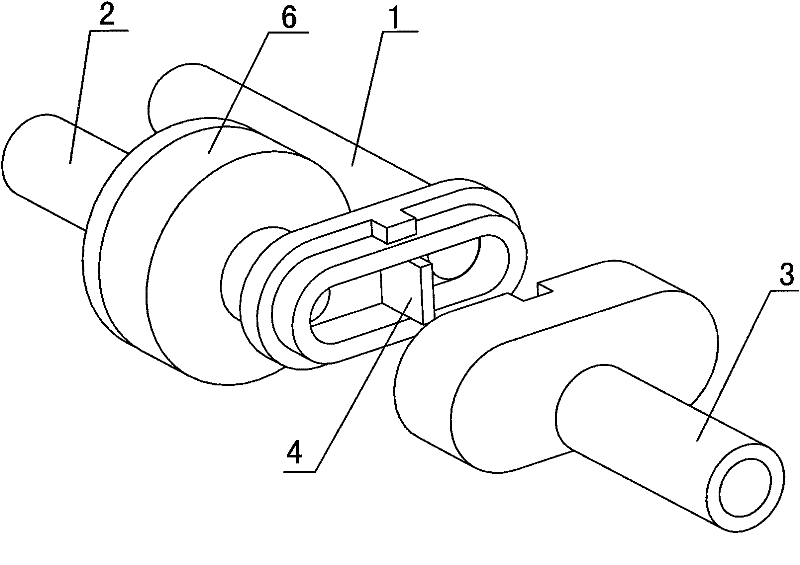

[0020] Such as Figure 1 to Figure 4 As shown, the tee pipe used in the fuel evaporative emission control pipeline has three branch pipes connected as a whole, which are respectively the first branch pipe 1, the second branch pipe 2 and the third branch pipe 3, wherein the first branch pipe 1, the second branch pipe The second branch pipe 2 is formed as the double end of the three-way pipe, and the third branch pipe 3 is the single end of the three-way pipe. There is a baffle 4, and the baffle 4 is located between the interfaces of the inner cavities of the two branch tubes at the double-head end. The baffle plate 4 can stop the liquid gasoline from entering into another branch pipe connected with the one-way valve from one of the pipes at the double end, so as to avoid the air blockage caused by the accumulation of gasoline in the branch pipe. The bottom of the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com