Simple method for measuring starch retrogradation degree

A determination method and technology of starch, applied in the direction of color/spectral property measurement, etc., to achieve the effect of simple and easy operation, high accuracy and short determination time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

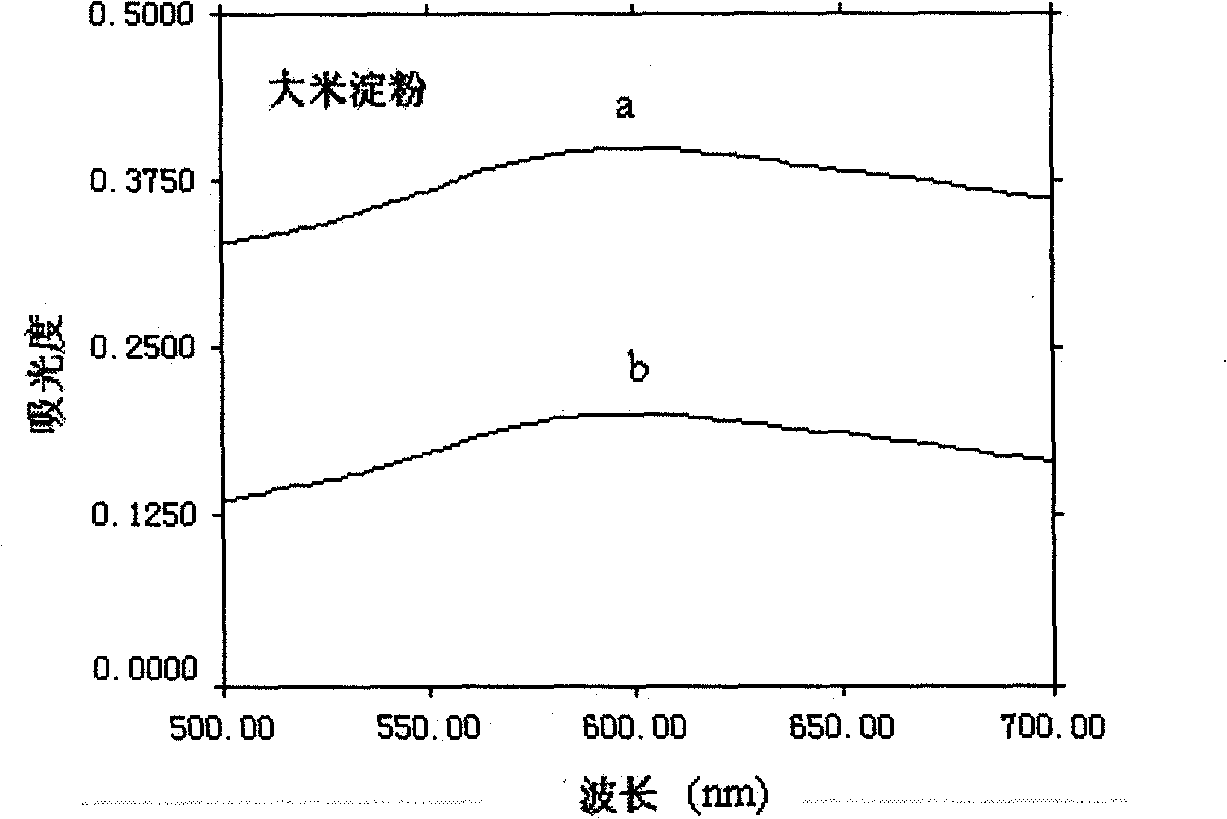

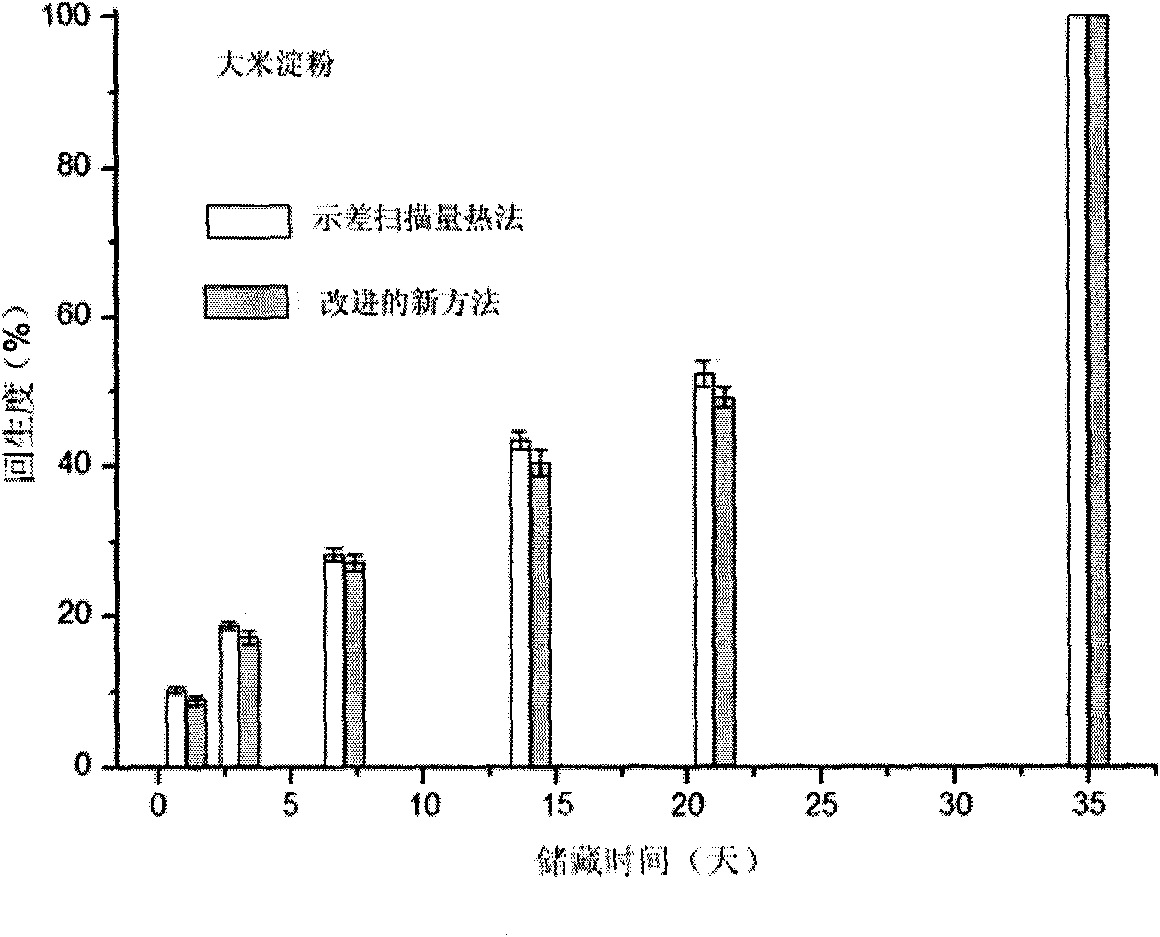

[0019] Determination of retrogradation of rice starch. Dry and prepare a series of rice starch retrograde samples at low temperature (32°C), crush them through 80 meshes; weigh 25 mg of crushed starch samples stored for 0, 1, 3, t, ..., 35 days; use 5 mL, 0.01 mol / Disperse and dissolve the sample in L sodium hydroxide solution, adjust the pH to neutral with hydrochloric acid solution (0.01mol / L) and dilute to 50mL with deionized water to obtain a dilution; take a certain volume of dilution (5mL) and add 2mL of standard KI Solution (w / w, 0.2% I 2 -2% KI), adjust the pH to 4 with acetate buffer, and make the volume to 50mL with deionized water; wait for the solution to react at 25°C for 15 minutes, at 600nm (by figure 1 visible) to measure the absorbance of each starch retrogradation sample; calculate the retrogradation degree according to the formula (compared with the differential scanning calorimetry measurement results see figure 2 ).

Embodiment 2

[0021] Determination of staleness of bread. Weigh each 3g of bread crumbs with different storage time, and dry them in a 32°C incubator until the moisture content is about 14% (w / w). The dried samples were pulverized through 80 mesh. Take a quantitative sample (25 mg) and disperse and dissolve the sample with 3 mL of sodium hydroxide solution (0.01 mol / L), adjust the pH to neutral with hydrochloric acid solution (0.01 mol / L) and dilute to 50 mL with deionized water to obtain a dilution; Take a certain volume of diluent (5mL), add 2mL of standard KI solution (w / w, 0.2% I 2 -2% KI), adjust the pH to 4 with acetate buffer and dilute to 50mL with deionized water; react the solution at 25°C for 15 minutes, measure the absorbance of the sample at 600nm; calculate the degree of retrogradation according to the formula.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com