An Automatic Loading System for Weighing Apparatus Type Evaluation

An automatic loading and type technology, applied in the direction of weighing equipment testing/calibration, etc., can solve the problems of accuracy impact, parts are easily damaged, and affect measurement accuracy, so as to reduce the impact and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

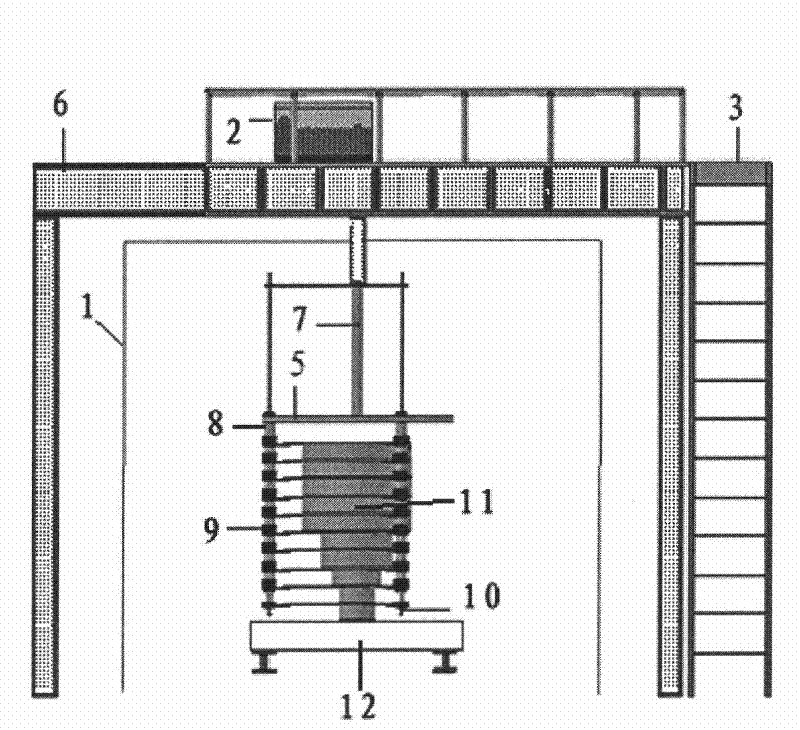

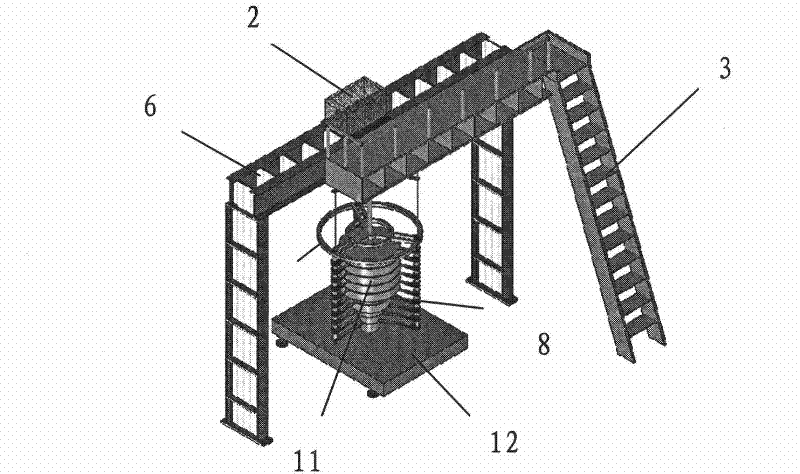

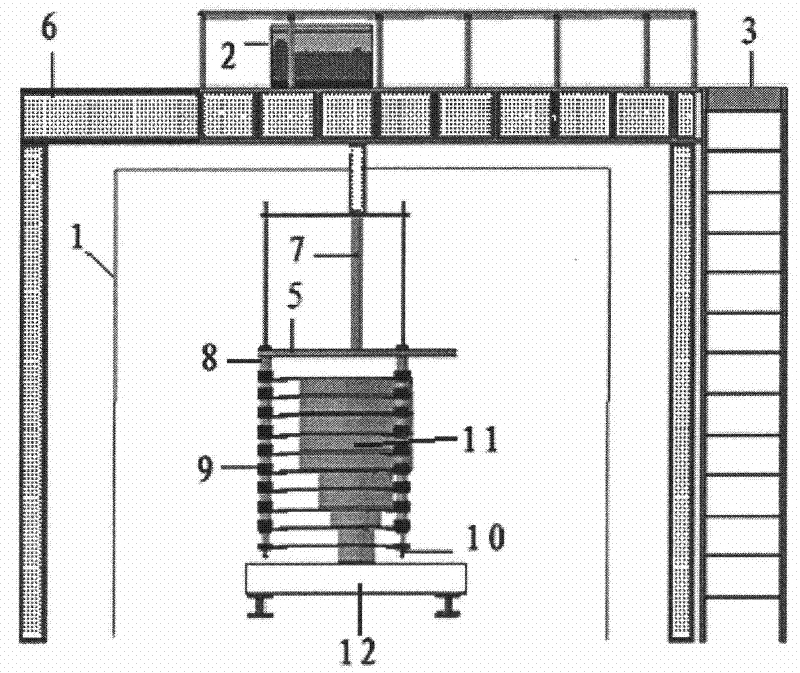

[0026] figure 1 It is a structural schematic diagram and an automatic loading system for weighing apparatus type evaluation of the present invention figure 2 It is a schematic diagram of the side structure of the present invention;

[0027] In the figure, an automatic loading system for weighing apparatus type evaluation, the system includes a driving mechanism 2, a loading mechanism and a loading support structure; the system also includes a load transfer component, and the drive mechanism 2 communicates with the load transfer component The loading mechanism is connected;

[0028] The driving mechanism 2 includes a motor for generating driving force; the load transmission component includes a screw 7, through which the driving force is transmitted to the loading mechanism to drive the loading action; the supporting loading structure includes a The beam frame 6 is used to support the loading mechanism.

[0029] In order to realize the loading process, the loading mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com