System implementing pipeline leak detection by utilizing infrasonic wave

A pipeline leakage and infrasound technology, which is used in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problem that the sudden detection of pressure waves is difficult to meet the practical application and difficult to adapt to the requirements of pipeline leakage detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The system for realizing pipeline leakage detection using infrasonic waves according to the present invention has a preferred embodiment as follows:

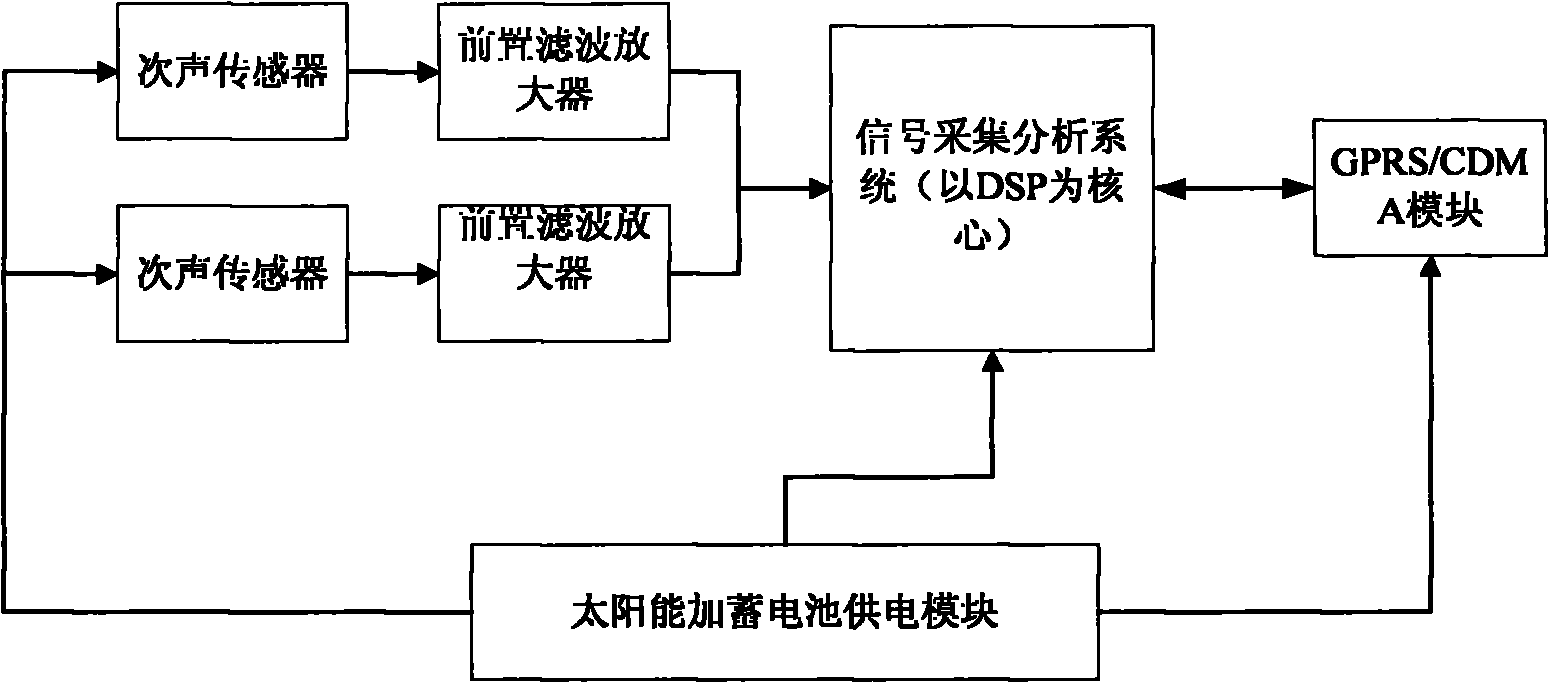

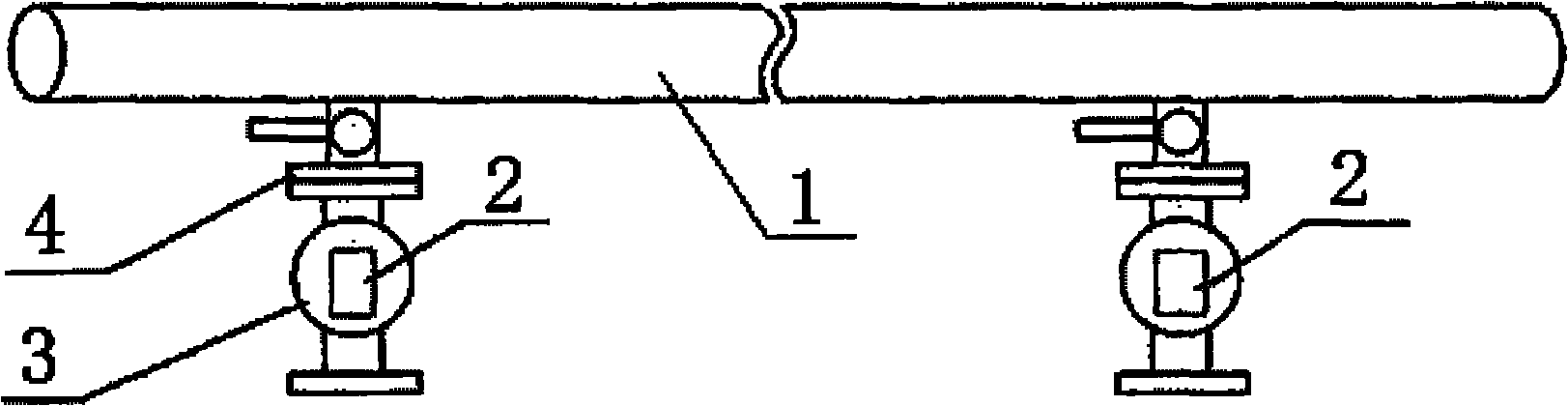

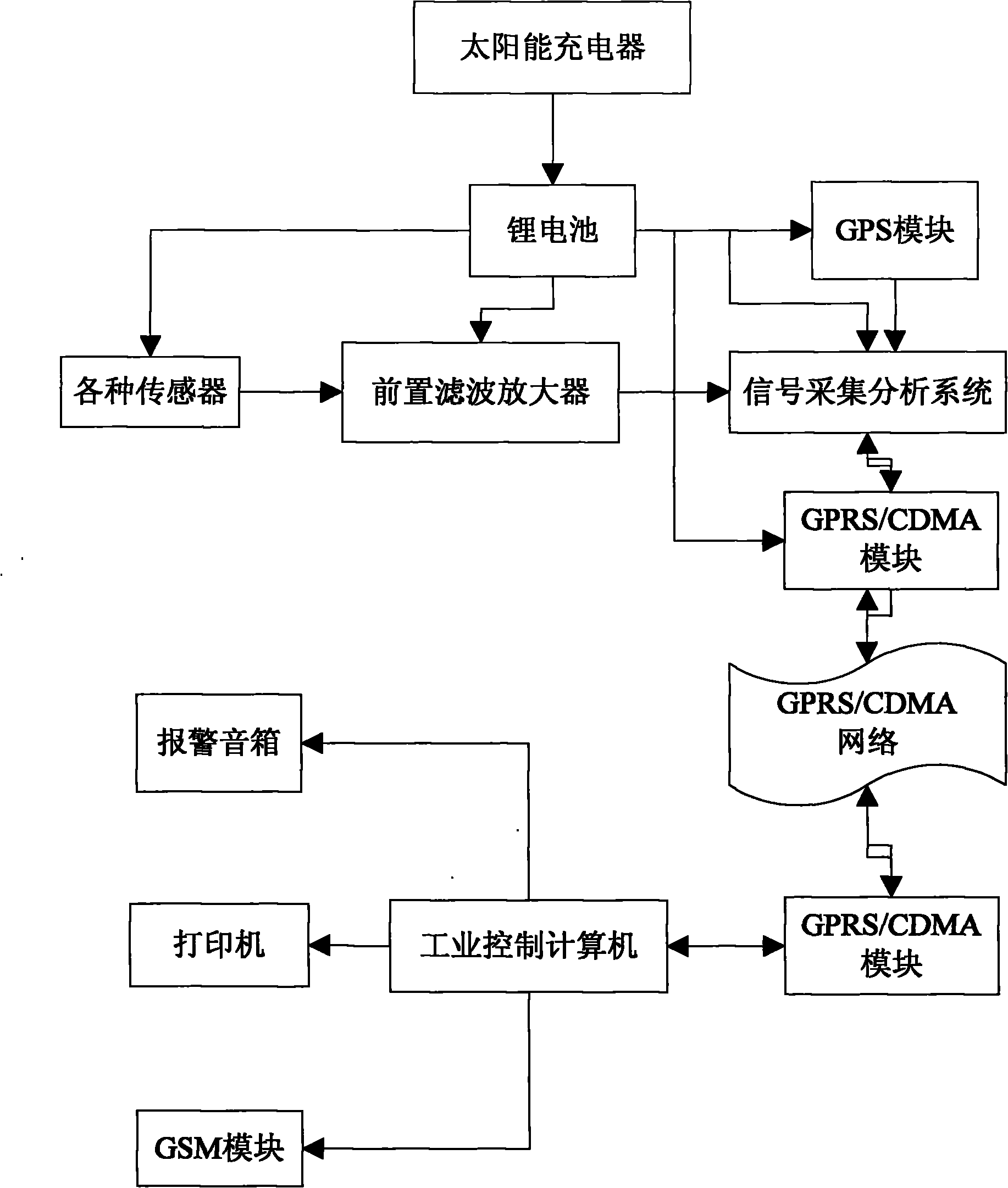

[0017] An upstream detection point and a downstream detection point are set on the pipeline to be detected, and at least one infrasonic wave sensor is respectively installed at the upstream detection point and the downstream detection point, and the infrasonic wave signal collected by the infrasonic wave sensor due to pipeline leakage is input to the Signal acquisition and analysis system;

[0018] The signal acquisition and analysis system determines the location of the leak according to the time difference between the arrival of the infrasound signal at the upstream detection point and the downstream detection point multiplied by the propagation speed of the sound wave in the fluid, and exchanges information with the outside through the communication module.

[0019] The frequency response range of the infrasonic sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com