Tandem shipbuilding method for chemical tanker

A chemical tanker and shipbuilding technology, applied in ship construction, ship parts, ships, etc., can solve the problems of the center line of the hull deviate from the center line of the slipway, difficult to meet the requirements, etc., to achieve the convenience of moving the ship, improve the utilization rate and production cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

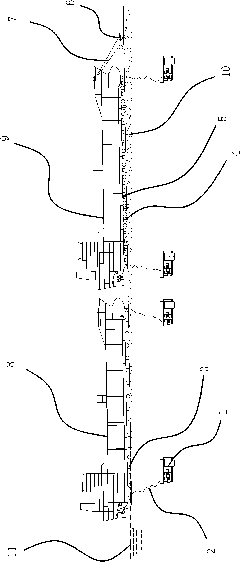

[0042] Such as figure 1As shown, the equipment involved in the present invention includes a berth 10 with a slope that can accommodate more than one ship. The berth 10 is provided with an air compressor 1 and a gantry crane, and is provided with an air bag 3 and a traction mechanism for displacement. A positioning mechanism for positioning the hull is also provided, and the positioning mechanism includes a manual jack 12, a steel pier 4, a wooden wedge 5 and a laser theodolite 13. The traction mechanism includes a winch 6 fixed on the berth 10 and positioned at the front of the bow, and a wire rope 7 is connected between the winch 6 and the hull. One end of the wire rope 7 is coiled on the winch 6, and the other end is connected with the hull, and the speed of the hull movement is controlled by controlling the release amount of the wire rope 7.

[0043] When the No. 1 ship 8 is built near the launching channel 11 at the front end of the berth 10, the stern section of the No. ...

Embodiment 2

[0051] The general content of this embodiment is the same as that of Embodiment 1, the difference is that in this embodiment, the second ship 9 only includes the stern section.

Embodiment 3

[0053] The general content of this embodiment is the same as that of Embodiment 1, and the difference is that the positioning mechanism in this embodiment includes a laser theodolite 13 positioned on one side of the hull and a steel pier 4 between the bottom of the hull and the ground, and the steel pier 4 There is a hydraulic buttress that can adjust its own height between the ship and the bottom of the hull. The hydraulic buttress includes a support with a screw that can be lifted and lowered. The screw is driven by a hydraulic device. There is a self-locking between the screw and the support. structure. The top of the screw rod is in contact with the bottom of the hull, and the bottom surface of the support is in contact with the top of the steel pier 4 . When it is necessary to position the hull section or the whole ship, at first the hydraulic support pier is placed on the steel pier 4, and the height of the hull is measured with the laser theodolite 13, and the protrusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com